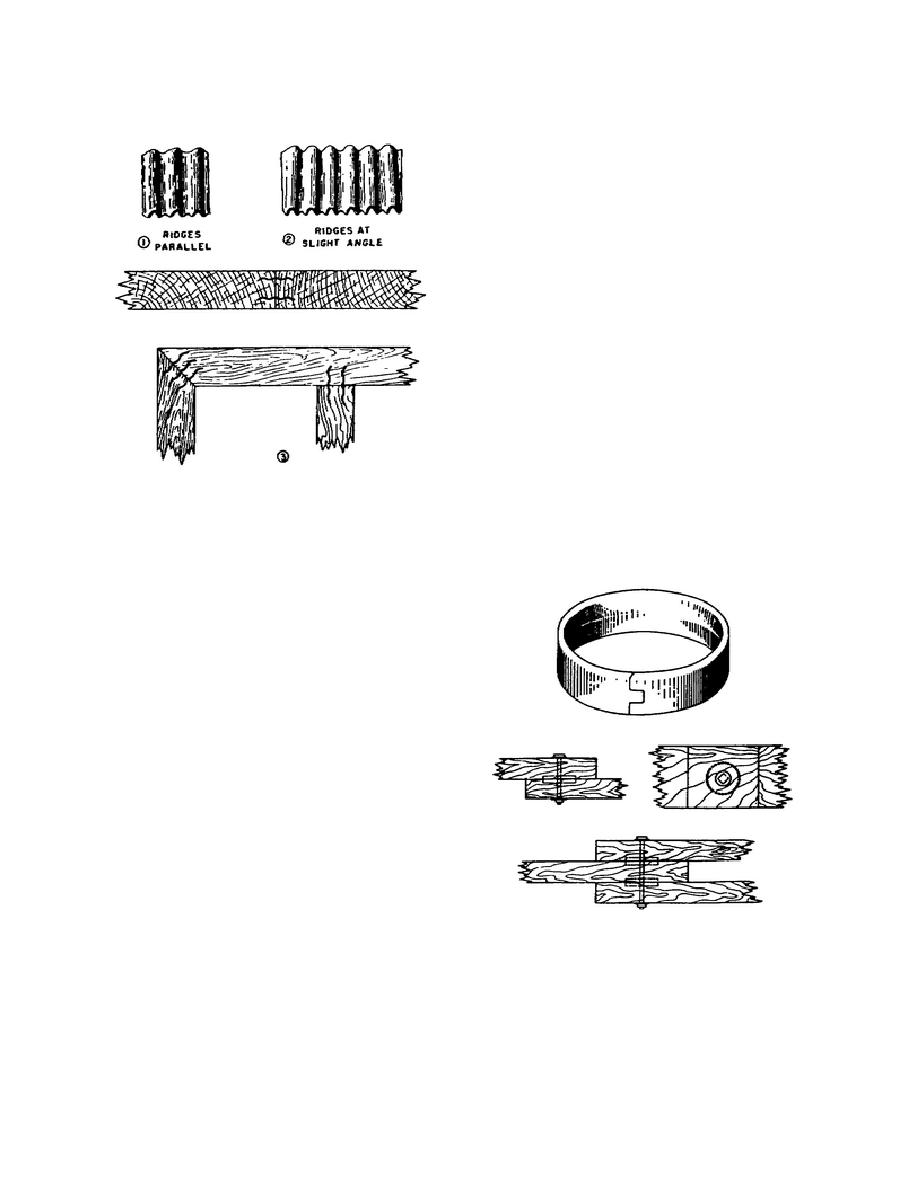

timber faces. (fig. 1-22). The grooves are made with

a special bit used in an electric, air, or hand drill. The

tongue-and-groove split in the ring permits

simultaneous ring bearing against the cone wall and

outer wall of the groove into which the ring is placed.

The inside bevel and mill edge facilitates installation

into and removal from the groove.

(2) Toothed rings. Toothed rings are

corrugated and toothed on both edges and are made

from 16-gage-plate low-carbon steel (fig. 1-23).

They are used between two timber framing members

in comparatively light construction and are embedded

into the contact faces of the joint members by means

of pressure.

1-26. EXCAVATIONS

In the theater of operations, there is little

excavation for building, but any excavating that is

done requires a set procedure. In excavating for a

building with earth floors, all that is necessary is a

Figure 1-21. Corrugated fasteners and their uses.

small trench to contain the sill (fig. 1-24). The

building may then be constructed and the grading on

nails in small timber. 3, figure 1-21 shows the proper

the inside done later, if necessary. In small buildings

method of inserting the fasteners.

where there are no wood floors, the earth should be

thrown on the inside to raise the

1-25. TIMBER CONNECTORS

a. General. Timber connectors are metal

devices used for increasing the joint strength in

timber structures. Efficient connections for either

timber-to-timber joints or timber-to-steel joints are

provided by the several types of timber connectors.

The appropriate type for a specific structure is

determined primarily by the kind of joint to be made

and the load to be carried. These connectors

eliminate much complicated framing of joints. Some

of the important advantages are that they simplify the

design of heavy construction provide greater

efficiency of material, reduce the amount of timber

and hardware used, and save time and labor. Many

types are used; however, the most common are split

rings and toothed rings.

b. Types and uses.

(1) Split rings. Split rings are made of

low-carbon steel in sizes of 2 1/2- and 4-inch

diameters. They are used between two timber faces

Figure 1-22. Split ring and its installation.

for heavy construction. They fit into grooves which

are cut half the depth of the ring into each of the

1-27

Previous Page

Previous Page