metal applications. If used for wood to metal

application, the head should be fitted to the wood

members. Metal surfaces are sometimes predrilled

and countersunk to permit the use of carriage bolts

metal to metal. Carriage bolts can be obtained from

1/4 inch diameter to 1 inch diameter, and up to 20

inches long. A common flat washer should be used

with carriage bolts between the nut and the wood

surface.

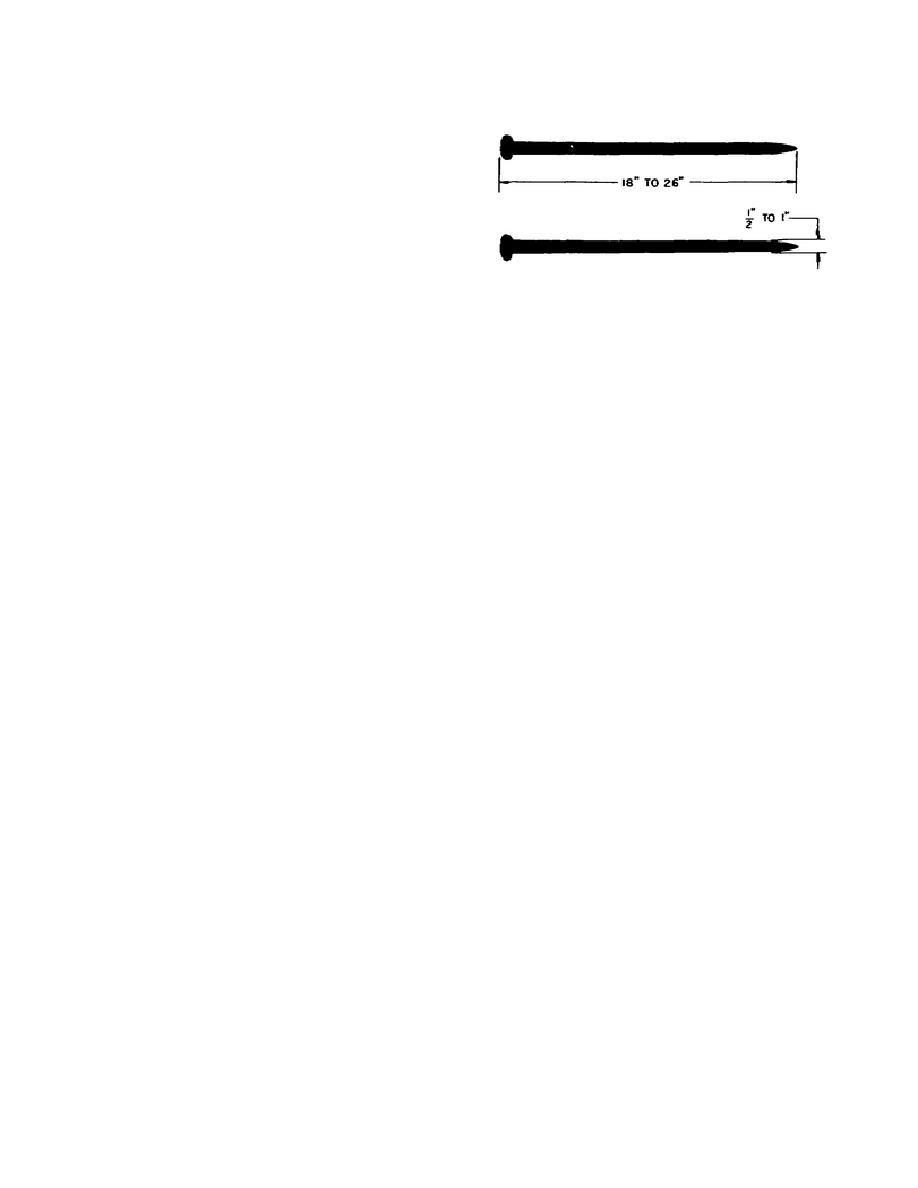

Figure 1-20. Driftpins (driftbolts).

(2) Machine bolts. Machine bolts are

made with cut National Fine or National Coarse

diameter from 1/2 to 1 inch, and in length from 18 to

threads extending in length from twice the diameter

26 inches. To use a driftpin, a hole slightly smaller

of the bolts plus 1/4 inch (for bolts less than 6 inches

than the diameter of the pin is made in the timber.

in length) to twice the diameter of the bolt plus 1/2

The pin is driven into the hole and held in place by

inch (for belts more than 6 inches in length). They

the compressive action of the wood fibers.

are precision made and generally applied metal to

1-24. CORRUGATED FASTENERS

metal where close tolerance is desirable. The head

may be square, hexagon, double hexagon, rounded,

a. General. Corrugated fasteners are one

or flat countersunk. The nut usually corresponds in

of the many means by which joints and splices are

shape to the head of the bolt with which it is used.

fastened in small timber and boards. They are used

Machine bolts are not slotted for screwdrivers.

particularly to strengthen miter joints. Corrugated

Selection of the proper machine bolt is made on the

fasteners are normally made of sheet metal of 18 to

basis of head style, length, diameter, number of

22 gage with alternate ridges and grooves. The

threads per inch, and coarseness of thread. The hole

ridges vary from 3/16 to 5/16 inch, center to center.

through which the bolt is to pass is bored to the same

One end is cut square; the other end is sharpened

diameter as the bolt and may, in some cases, be

with beveled edges.

slightly larger. Machine bolts are made in diameters

b. Types.

There are two types of

from 1/4 inch to 3 inches and may be obtained in any

corrugated fasteners: one with the ridges running

length desired.

parallel (1, fig. 1-21), the other with ridges running at

(3) Stove bolts. Stove bolts are less

a slight angle to one another (2, fig. 1-21). The latter

precisely made than machine bolts. They are made

type has a tendency to compress the material since

with either flat or round slotted heads and may heave

the ridges and grooves are closer at the top than at the

threads extending over the full length of the body,

bottom.

over part of the body, or over most of the body. They

c. Size. These fasteners are made in

are generally used with square nuts and applied metal

several different lengths and widths. The width

to metal, wood to wood, or wood to metal. If flat

varies from 5/8 to 1-1/8 inches, while the length

headed, they are countersunk; if round headed, they

varies from 1/4 to 3/4 inch. The fasteners are also

are drawn flush to the surface. Either type may be

made with different numbers of ridges, ranging from

driven with a screwdriver, or may be held with a

three to six ridges per fastener.

screwdriver while a wrench is used on the nut.

d. Use. Corrugated fasteners are used in a

1-23. DRIFTPINS (fig. 1-20)

number of ways: to fasten parallel boards together,

Driftpins, sometimes called driftbolts, are long,

such as in fashioning table tops; to make any type of

heavy threadless pins used to hold heavy pieces of

joint; and to replace nails when nails might split the

timber together. Driftpins have heads and vary in

timber. The fasteners have a greater holding power

than

1-26

Previous Page

Previous Page