special-purpose screws are made of brass aluminum,

b. Screw sizes. Wood screws vary in

or stainless steel. Ordinary soft-steel screws may be

length from 1/4 inch to 6 inches. Screws up to 1 inch

bright finished or blued or they may be zinc,

in length increase by eighths of an inch screws from

cadmium, brass, or chrome plated. Wood screws

1 to 3 inches by quarter inches, and screws from 3 to

have gimlet points and are threaded for

5 inches by half inches. There are also 6-inch

approximately two-thirds of their length.

screws. Each length is made in a number of shaft

sizes indicated by an arbitrary number that represents

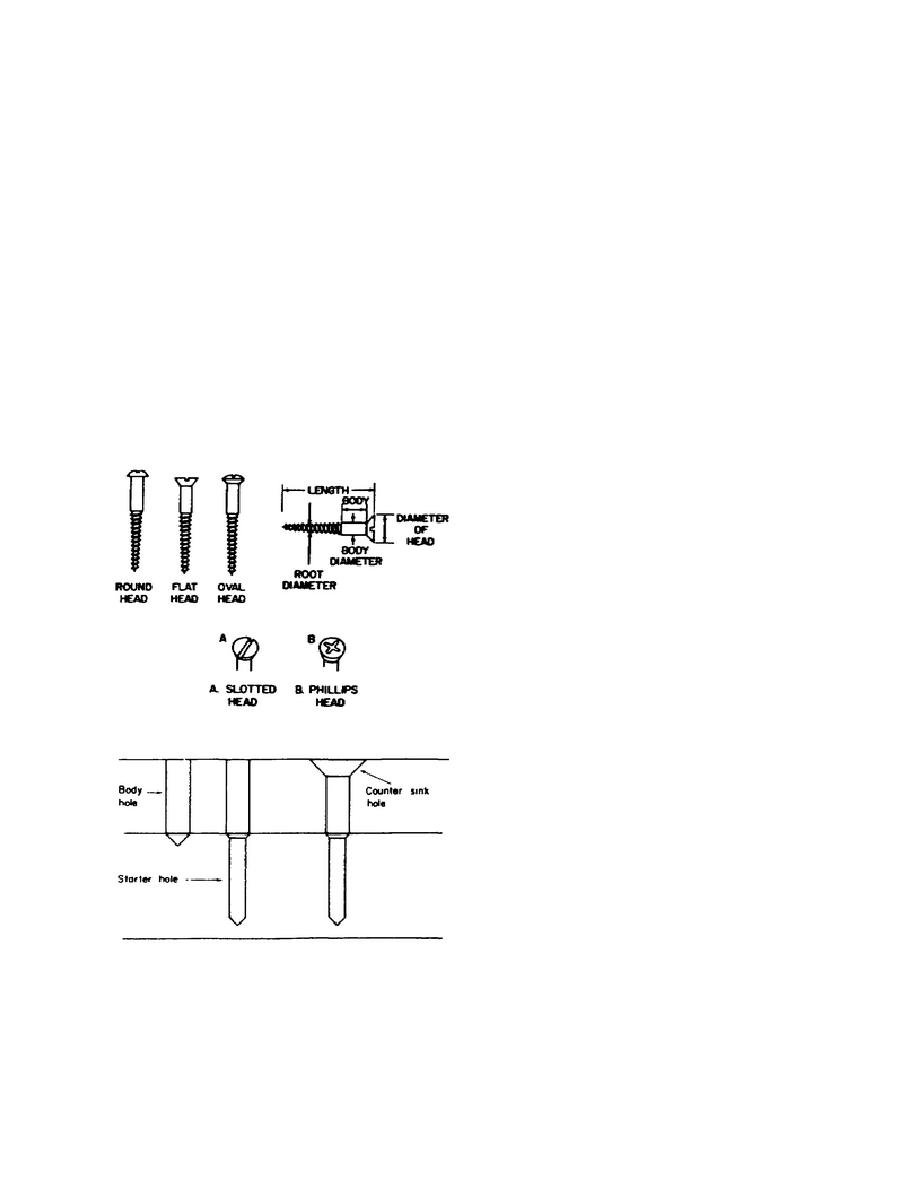

a. Types of wood screws. Wood screws

no particular measurement but indicates relative

are designated according to head styles as shown in

diameters. Tables 1-5 and 1-6 provide size, length,

figure 1-16.

The types commonly used in

gage, and applicable drill and bit sizes for screws.

construction are: slotted flathead, oval head, round

head, and Phillips head. To prepare wood for screws,

c. Lag screws. The proper name for lag

as shown in figure 1-17, bore a pilot or body hole the

screws in the nomenclature of the Army supply

diameter of the screw that is to be used through the

system is bolt, lag, wood-screw type. These screws

piece of wood that is to be fastened on. Then bore a

are sometimes required in frame construction. They

smaller starter or lead hold in the piece that is to be

are longer and much thicker bodied than common

fastened to, to avoid hard turning and the possibility

wood screws and have coarser threads which extend

of splitting the wood. If flatheaded screws are to be

from a cone or gimlet point slightly more than half

used the pilot or body hole should be countersunk.

the length of the screw. Both square- and hexagon-

headed lag screws are usually driven by a wrench.

Combined with expansion shields or anchors they are

used to attach timbers to existing masonry.

d. Expansion shields. Expansion shields,

or anchors as they are sometimes called, are inserted

in a predrilled hole. After the expansion shield is

inserted, the bolt or occasionally another type of

fastener such as a screw or even a nail is driven into

the shield, causing it to expand and become firmly

wedged in place (fig. 1-18).

1-22. BOLTS

a. General. Bolts are used in construction

when great strength is required or when the work

under construction must be frequently disassembled.

Figure 1-16. Types of wood screws.

Their use usually requires nuts for fastening and

washers to protect the surface of the material to be

fastened. Bolts are selected according to specific

requirements in terms of length, diameter, threads,

style of head, and type. Proper selection of head

style and type of bolt will result in good appearance

as well as good construction. The use of washers

underneath the nut or underneath both the nut and the

bolt head will avoid marring wood surfaces and

permit additional torque in tightening.

Figure 1-17. Method of preparing wood for screws.

1-23

Previous Page

Previous Page