Example Problem

Design the form for the roof of a concrete water tank to be 6 inches thick, 20 feet wide, and 30 feet long. The slab

will be constructed 8 feet above the floor (to the bottom of the slab). Available materials are 3/4-inch plywood

and 4- by 4-inch S4S (surfaced on four sides) lumber. Mechanical buggies will be used to place concrete.

Step 1. Specify the materials for construction. Sheathing 3/4-inch plywood (strong way); joists, 4- by 4-inch

(S4S) shores, 4- by 4-inch (S4S); stringers, and 4- by 4-inch (S4S) lumber.

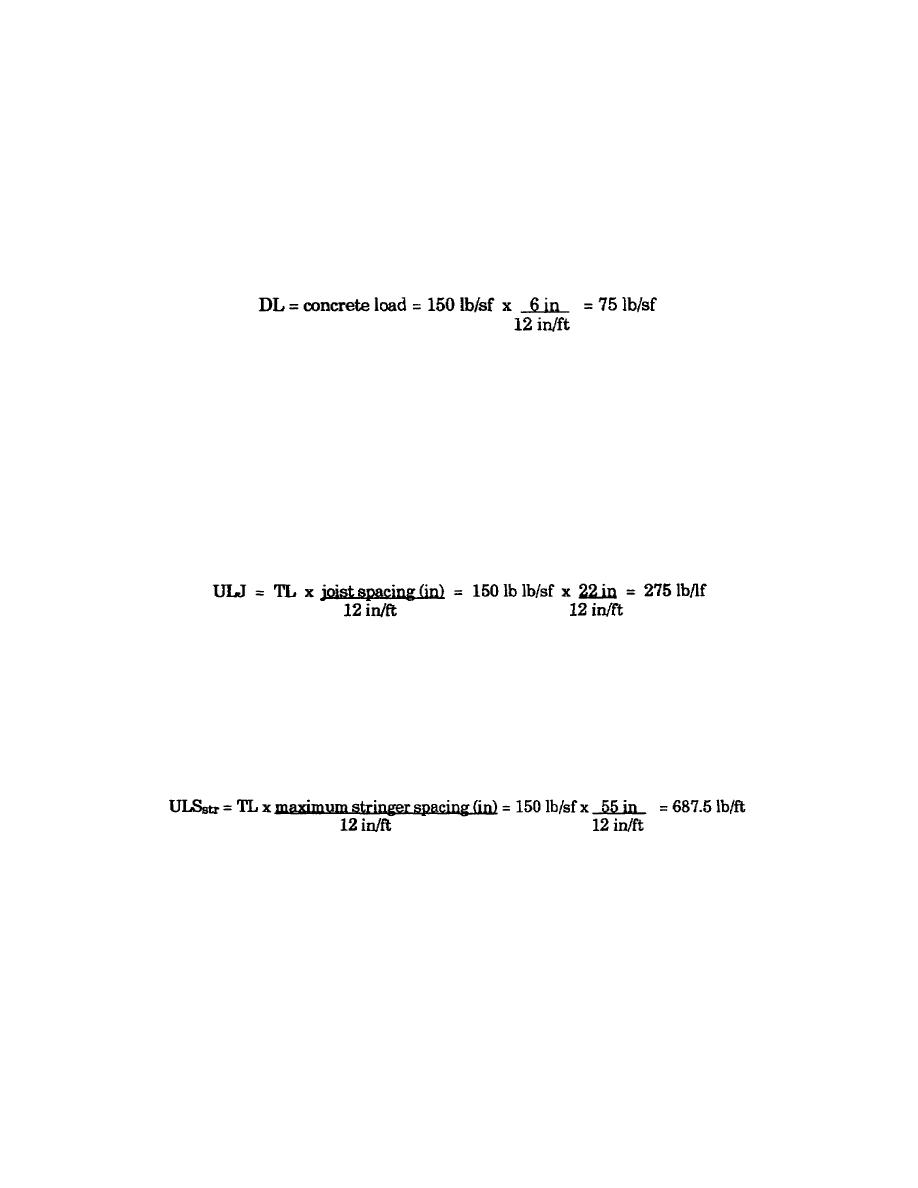

Step 2. Determine the maximum total load.

LL- = personnel and equipment = 75 lb/sf

TL = DL + LL = 75 lb/sf + 75 lb/sf = 150 lb/sf

Step 3. Determine the maximum joist spacing. Use Table 3-2 on page 3-7.

3/4-inch plywood (strong way) and TL = 150 lb/sf

Joist spacing = 22 inches

Step 4. Calculate the ULJ.

Step 5. Determine the maximum stringer spacing. Use Table 3-3 on page 3-9.

Load

= 275 lb/lf

Joist material

= 4- by 4-inch

Maximum stringer spacing

= 55 inches

Step 6. Calculate the uniform load on the stringer (ULSstr).

Step 7. Determine the maximum shore spacing (use Table 3-3). Spacing is based on stringer strength. (Use

Table 3-4 on page 3-11.)

Load

= 687.5 lb/lf (round up to 700 lb/lf)

Stringer material

= 4- by 4-inch (S4S)

Maximum shore spacing

= 35 inches

Spacing based on the shore strength and end bearing of the shore on the stringer. Use Table 3-7 on page 3-21 and

Table 3-8.

Allowable load based on shore strength (see Table 3-7).

3-2

EN5466

Previous Page

Previous Page