h = 10 ft (from example problem)

y = 6 feet (from example problem)

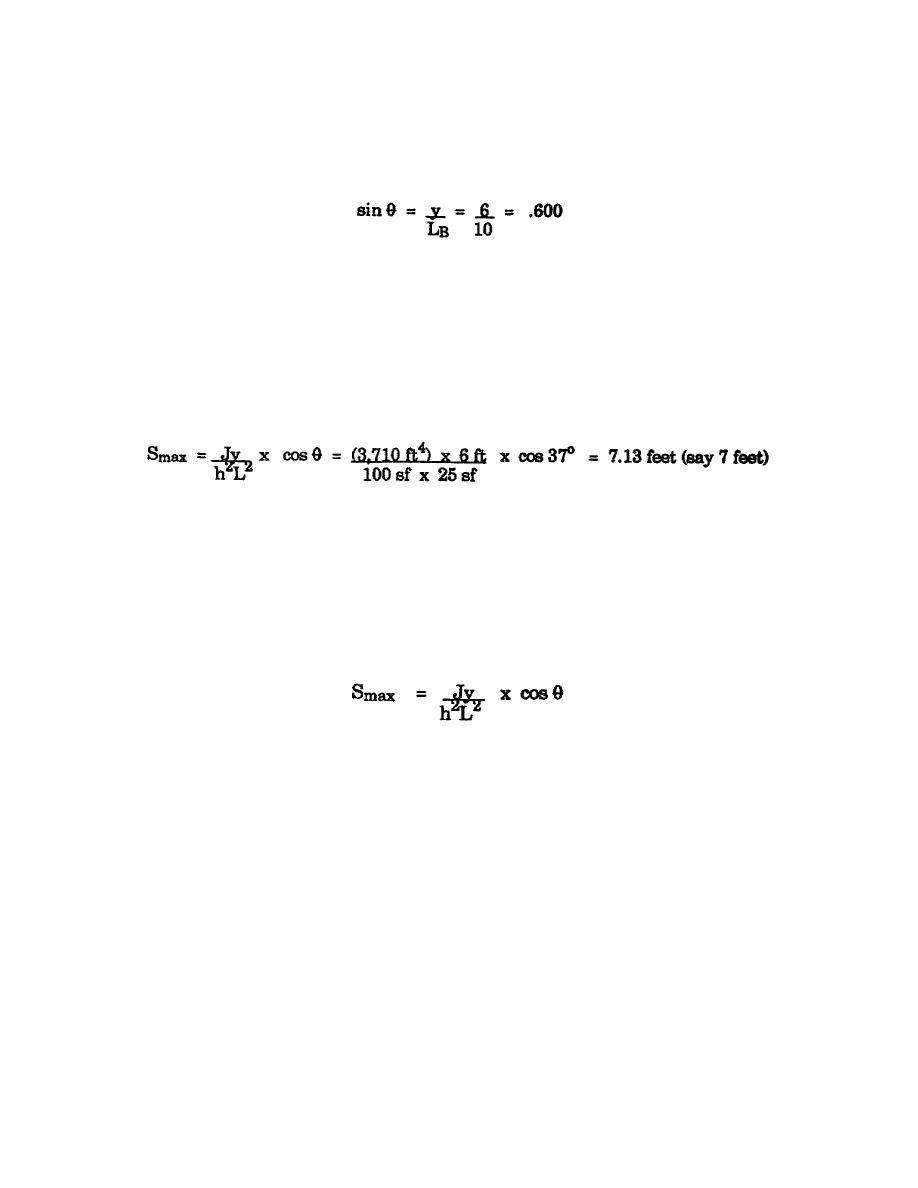

Step 1. Determine angle of placement, θ.

θ= sin1 (.600) = .600 = 37

Step 2. Determine L (actual supported length of brace). Since the Lmax for all 2-inch material is 6 1/4 feet and

the brace in this problem is 10 feet long, you will have to use something to support the braces (usually 1- by 4-

inch or 1- by 6-inch material). The best position to put this support would be in the middle of the brace, thus

given L = 6 feet.

Step 3. Determine Smax from the formula.

Thus, using 2- by 6-inch by 10-foot braces applied to the wall form at y = 6 feet, you should place these braces no

further apart than 7 feet. Remember also that after the braces are properly installed, connect all braces to each

other at the center so deflection does not occur.

NOTE: This procedure determines the maximum safe spacing of braces. There is no doctrine that states the

braces must be placed 7 feet apart--they can be less!

Discussion. To fully understand the procedure, the following points lend insight to the formula:

Derivation of the formula has a safety factor of 3.

For older or "green" lumber, reduce Smax according to judgement.

For maximum support, attach braces to the top edge of the forms (or as close as practicable). Also, better

support will be achieved if θ = 45.

Remember to use intermediate supports whenever the length of the brace (LB) is greater than Lmax.

Whenever there are choices of material, the larger size will always carry greater loads.

To prevent overloading of the brace, support should be placed no closer together than 2 feet for all 2-inch

material, nor 5 feet for all 4-inch material. This is necessary to prevent crushing of the brace.

EN5466

3-18

Previous Page

Previous Page