Step 13. Maximum tie spacing = 21 inches

Step 14. Because maximum tie spacing is greater than maximum stud spacing (Step 7), reduce the tie spacing to

18 inches and tie at the intersection of each stud and double wale.

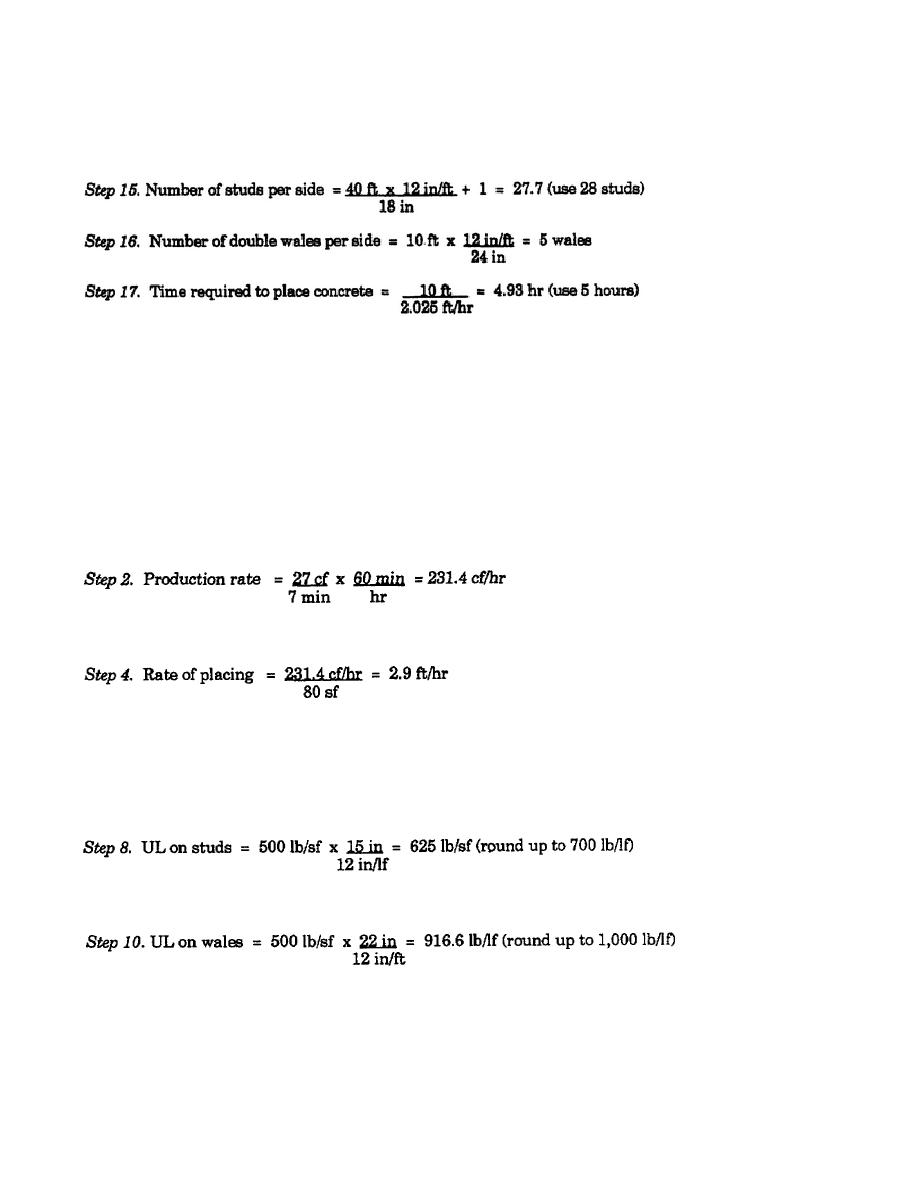

Example Problem 2

Design the form for a concrete wall 40 feet long, 2 feet thick, and 10 feet high. An M919 concrete mobile mixer

is available, and the crew can produce and place a cubic yard of concrete every seven minutes. The concrete

placing temperature is estimated at 70F. The form materials you have are 2- by 4-inch lumber, 3/4-inch

plywood, and 3,000-pound (breaking strength) snap ties.

Solution Steps:

Step 1. Materials available: studs, 2 by 4 (single); wales, 2 by 4 (doubled); sheathing, 3/4-inch plywood (strong);

ties, 3,000-pound snap ties

Step 3. Plan area of form = 40 ft x 2 ft = 80 sf

Step 5. Concrete placing temperature = 70F

Step 6. Maximum concrete pressure (refer to Figure 3-3, page 3-5) = 500 lb/sf

Step 7. Maximum stud spacing (refer to Table 3-2, page 3-7) = 15 inches

Step 9. Maximum wale spacing (refer to Table 3-3, page 3-9, using 700 lb/lf load) = 22 inches

Step 11. Tie spacing based on wale size (refer to Table 3-4, page 3-11, using 1,000 lb/lf load) = 27 inches

EN5466

3-14

Previous Page

Previous Page