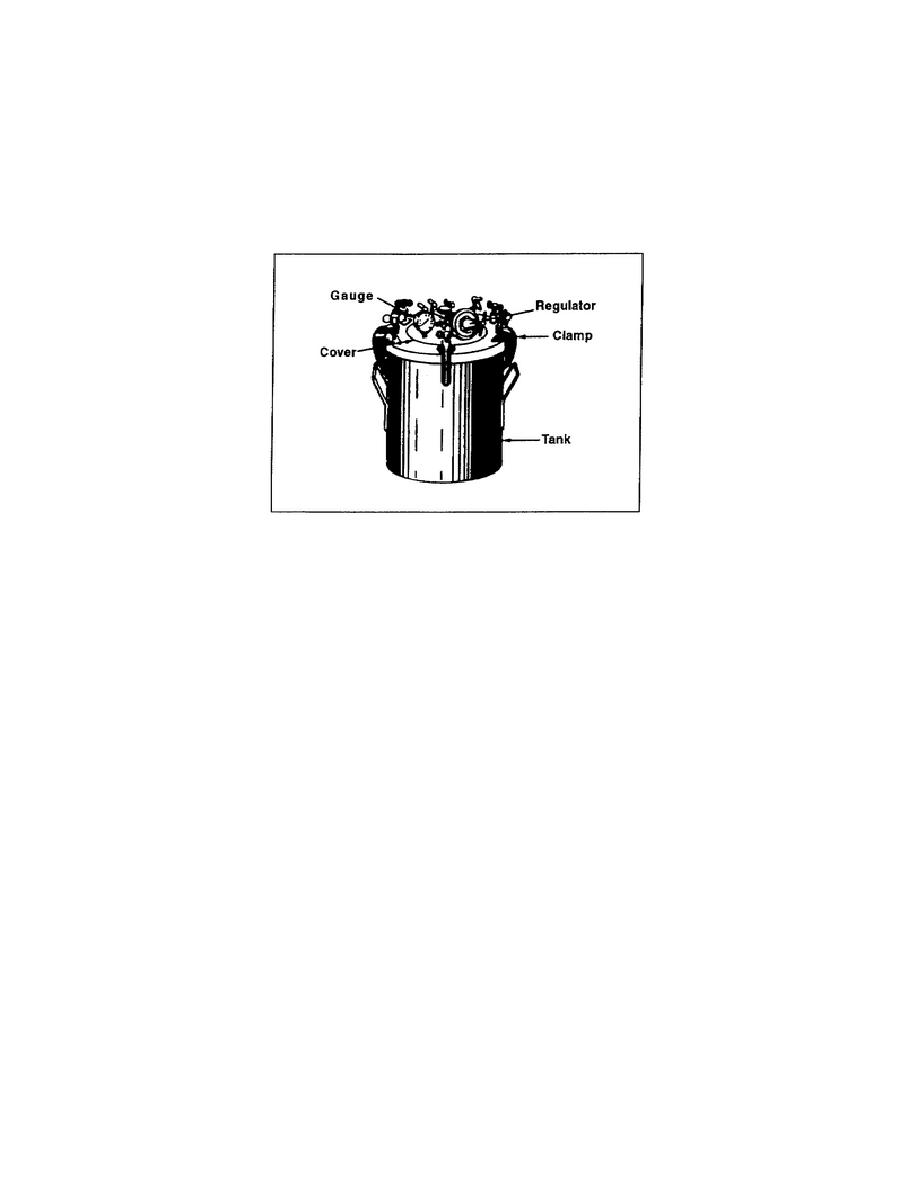

i. Pressure-Fed Paint Tank.

(1) A pressure-fed paint tank (Figure 3-40) is a large metal container that provides paint

material at a constant flow and at uniform pressure to the spray gun. The spray gun is connected to the

tank with two hoses, one for air and the other for paint material. The tanks range in size from a 2 to 60

gallons. The basic tank consists of a container with a clamp-on lid, an air-pressure regulator, and

connections for fluid and air.

Figure 3-40. Pressure-fed paint tank

(2) In actual operation, air pressure from a compressor or some other air supply is forced into

the paint tank. This air pressure causes the paint to flow out of the tank, through a fluid hose, to the

spray gun. When the paint reaches the gun head, it comes in contact with air that is passing through the

spray gun, then the paint is atomized and sprayed.

3-8. Spray-Gun and Paint-Tank Cleaning. Thoroughly clean the paint spray gun and the paint tank

after each use. Remove the gun cap, wash and wipe out the tank or the spray-gun cap. Pour a small

amount of solvent or thinner into the tank or cup, reassemble and apply air pressure until the solvent or

thinner has been blown through the hose and gun. Finish by wiping off the units with a cloth that is

moistened with solvent or thinner.

When air or paint passages become clogged with paint, it is necessary to dissemble the units and soak all

metal parts in thinner or a paint-remover solution. After the solution has softened the paint in the air or

paint passages, take an appropriate-sized soft wire and work it back and forth through the passages until

they are open and clean.

NOTE: Do not use lye or any other caustic-alkali solution to clean paint-spraying equipment.

3-9. Spray-Gun and Paint-Tank Storage. Coat the surfaces of moving parts with a thin oil film

whenever a gun or tank is stored for an indefinite time. Lubricate the spray

EN0562

3-32

Previous Page

Previous Page