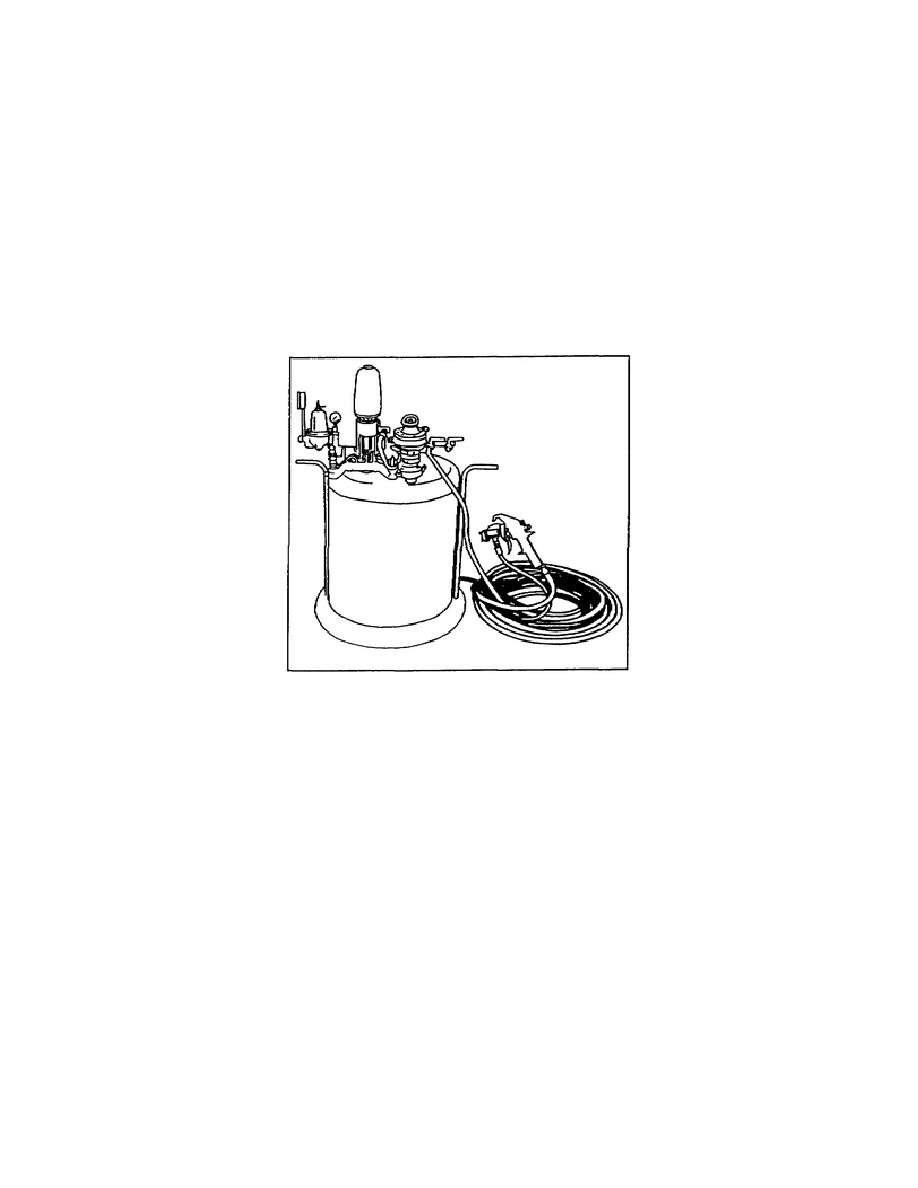

3-12. Airless Spray Systems.

a. In an airless spray system (Figure 3-43), the spray is created by forcing paint through a

restricted orifice at very high pressure. Paint atomization occurs without the use of air jets, thus the

name airless spray. Liquid pressures from 1,900 to 2,600 pounds per square inch are developed in

special air-operated, high-pressure pumps and delivered to the gun through a single hose line.

b. The system provides a very rapid means of covering large surfaces with a wide-angle spray

without producing overspray mist or rebound. The single, small-diameter hose makes gun handling

easy. The spray produced has a full wet pattern for quick film buildup. However, the system requires

extra care when lapping and stroking to avoid excessive coverage that would result in runs, sags, or

wrinkles.

Figure 3-43. Airless spray system

An airless unit with a self-contained heater (Figure 3-44, page 3-36) is also available. The advantage of

the hot sprayer is that it uses heat rather than thinner as the viscosity-reducing agent. As a result, the hot

sprayer is very compatible with VOC regulations.

3-35

EN0562

Previous Page

Previous Page