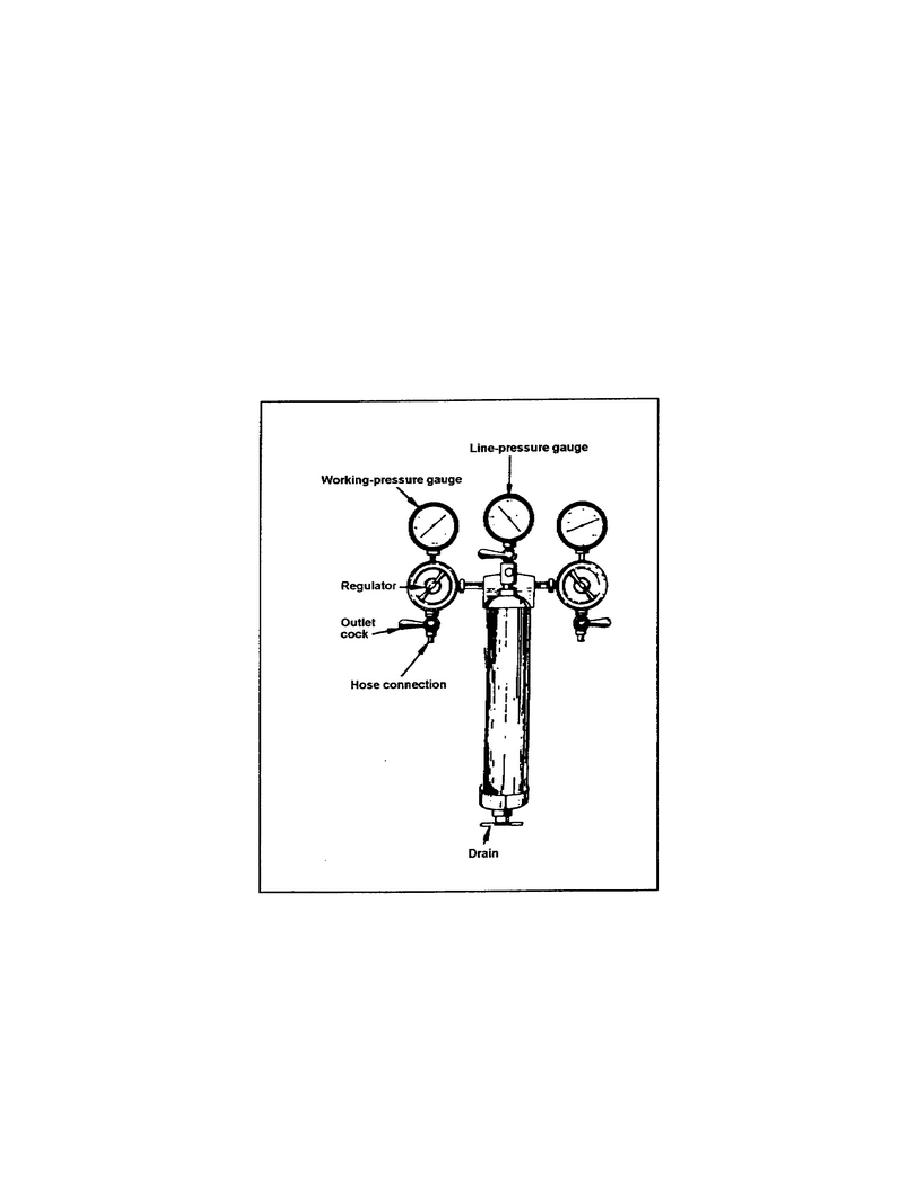

3-14. Air Transformer. Supply spray guns with clean, moisture-free, regulated air by installing an air

transformer (Figure 3-46) in the main air-line. The air transformer separates oil, dirt, and water from the

compressed air before it enters a spray gun; reduces the pressure on the main air-line to the desired

working pressure; and provides convenient hose connections for one or more spray guns. The

transformer has gauges which indicate the working pressures at the outlets.

Whenever an air transformer has only one working-pressure regulator, all attached spray guns will have

the same working pressure. However, if the transformer has two working-pressure regulators, as shown

in Figure 3-46, the attached spray guns are regulated by different working pressures. Use an air

transformer in all finishing paint shops where a supply of clean, moisture-free, regulated air is required.

When a regulated supply of air is available, a condenser is used to separate oil and moisture from the air.

Conventional spray systems have basic similarities. There must be an adequate source of compressed

air, a paint supply, and a spray gun for controlling the combination of air and paint in an atomized cloud

against the surface to be coated.

Figure 3-46. Air transformer

3-15. Spray Booth. A permanent spray-paint shop requires a well-ventilated and well-illuminated

spray booth. Figure 3-47, page 3-39, shows a portable spray booth that is ventilated by the deflector

plate shown in the back. It is illuminated by floodlights recessed in the walls of the booth. Portable

floodlights should also be available for the

3-39

EN0562

Previous Page

Previous Page