gun air valve daily with light oil. Keep all spray-gun packings, such as the fluid needle packing, soft

and pliant by occasional applying oil.

3-10. Hoses. There are two types of hoses-air and fluid:

a. Air. Air hoses are generally lightweight, flexible, kink-free, and will withstand pressures as

recommended by the manufacturer. For proper spray-gun equipment operation, the gun must receive an

adequate supply of compressed air. Ensure that the required amount of air is applied by using air hoses

of the proper size.

b. Fluid. Fluid hoses are usually made of synthetic rubber and are used with all types of

painting materials, solvents, and oils. Fluid hoses are cleaned at the same time as the gun when thinner

or solvent is forced through them by air pressure.

3-11. Air Compressors.

a. Air compressors are mechanical units designed to continuously supply compressed air at a

specific pressure and volume. Compressors have an electric motor or a gasoline engine. The Army

painter is primarily concerned with two types of air compressors-low pressure and high pressure.

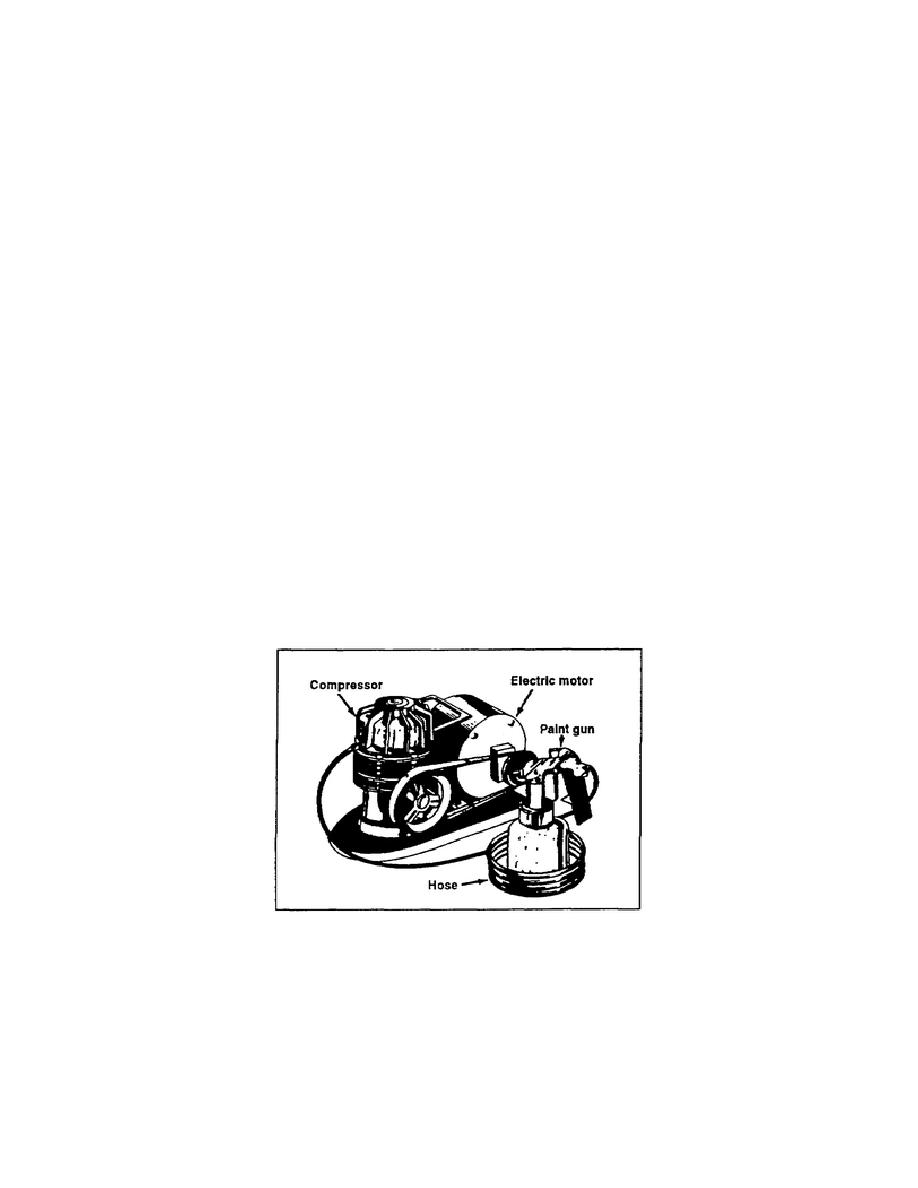

(1) Low Pressure. The low-pressure air compressor shown in Figure 3-41, weighs

approximately 50 pounds. The overall weight of this unit includes the air-pressure pump, the air-

pressure tank, and the driving unit. Since the spray unit is designed to operate on pressures from 20 to

40 pounds per square inch, you should exercise caution against applying higher pressures. Because this

gun operates at low pressures, it is not recommended for spraying quick-drying paints, lacquers, or

enamels.

Figure 3-41. Low-pressure air compressor (electric motor)

(2) High Pressure. Use this compressor for large jobs where heavy-duty spray equipment is

required. A high-pressure air compressor is shown in Figure 3-42, page 3-34.

3-33

EN0562

Previous Page

Previous Page