rubber seals, to close the space between the ribs of the

panel.

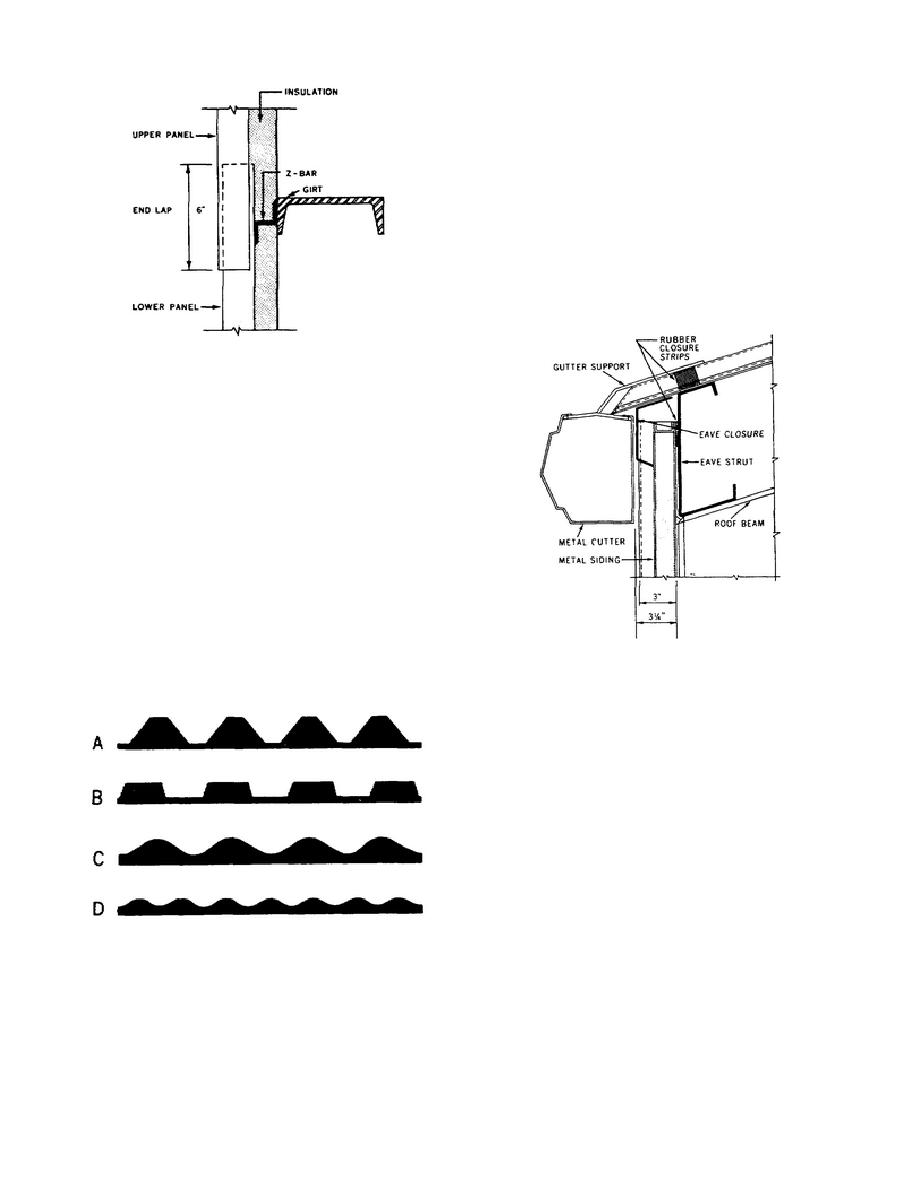

5-23. Figure 42 also illustrates the type of information

you can get from the master file of drawings in the

drafting section. This drawing shows a side view of each

part of the eave assembly. Each part is identified by

shape, name, size, or type of material. Check the drawing

file to locate hidden parts of the building so that you can

plan your work accordingly.

5-24. Sheet metal siding is fastened to the girts, base

angle, and eave strut or gable angle with self tapping

sheetmetal screw. When fastening steel to steel, you can

use steel screws or

Figure 40. End lap of exterior wall panel.

a wall, they are formed by lapping an upper panel over a

lower panel, as shown in Figure 40. A Z-shaped bar is

used at the girt where the splice is made. The metal

covering of the lower panel extends above the Z-bar, and

the metal covering of the upper panel laps over the lower

panel to form a 6-inch lap joint.

5-21. A solid rubber seal is used to make a waterproof

joint where ribbed panels overlap a smooth surface.

Figure 41 (A, B, C, and D) shows the shape of the rubber

seals used with roof and wall galvanized sheet metal

panels (A), aluminum ribbed panels (B), asbestos-cement

panels (C), and corrugated glass panels (D). The seals are

placed under the panel to prevent moisture from getting

between the panel and the smooth surface.

5-22. Special rubber seals may also be used at eave

struts, as shown in figure 42. Metal closure strips may be

Figure 42. Eave assembly.

needed, in addition to the

cadmium coated, rust resistant screws. These coated

screws are also used to fasten aluminum panels to steel

frames.

5-25. When aluminum panels are placed on a steel

frame, some type of separator must be used between the

different metals. This separator is usually provided by

coating the steel (area of contact) with an asphalt paint.

You can also use a layer of waterproof paper or asphalt

saturated felt as the separator.

5-26. In metal construction, it is frequently impossible

to prevent the contact of dissimilar metals. This contact

may result in the corrosion of one of the metals and the

protection from

Figure 41. Rubber seals.

23

Previous Page

Previous Page