is fastened to the lower ends of the rafters. The lower end

relocate. When they are no longer needed in one area,

of the rafter is seated on the top plate of the sidewalls, as

they can be shipped to an area where they can serve a

shown in figure 30. The joint made by the joist and rafter

useful function. We will concentrate our attention upon

is very important The joist helps to prevent the lower end

two metal buildings that are frequently used: the

of the rafter and the top of the wall from moving outward.

advanced base hut and the light steel frame buildings.

Perhaps you have noticed buildings where the sidewalls

5-2. Advanced Base Hut. The advanced base hut is

bowed outward and the ridge sagged in the middle. This

usually referred to as a "quonset hut". The standard size

is possible when the rafter and top plate pull loose from

is 20 by 48 feet. However, you will find that some of

the ceiling joist. The load on the rafter forces the upper

them are two or three times as long as this. They are

part of the wall outward, and the ridge line becomes

planned so that they can be assembled in sections 8-foot

lower. This also happens in permanent structures but is

lengths to make a building 8, 16, 28, etc., feet long. They

most common in light frames, where fewer and lighter

are easily adapted for quarters, office space, workshops,

ceiling joist are used.

training areas, supply storage, or any other function that

4-23. The rafter spacing is the same as stud spacing,

can be placed within them. Nails, screws, and bolts used

4-foot on-center. A knee brace fastened to the rafter,

in the assembly of the quonset hut are easily removed

ceiling joist, and wall stud is used every 12 or 16 feet for

when repair or disassembly of the unit is required. The

the length of the building. One-inch sheathing boards are

primary parts of this hut are the floor and wall, so let's see

used for the roof deck. Roll roofing is used as the roof

how they are put together.

5-3. Floors. The floor of the hut consists of a metal

covering. There is no roof overhang at the eave or gable,

and the roof covering is lapped down the side walls to

frame with a plywood covering. The main support of the

prevent leaks along the edge of the roof.

building is provided by five girders that run the length of

4-24. The interior of the light frame prefab is usually

the building.

These I-shaped girders are spaced

open, and leaks are easily located by a visual inspection.

approximately 5 feet 1 inch on-center to provide support

When a ceiling and partitions are used in the building,

for the floor joists. The girder, as we called it in the

you must locate leaks by entering the attic or going on the

wooden building, is referred to as an I-beam (its shape) or

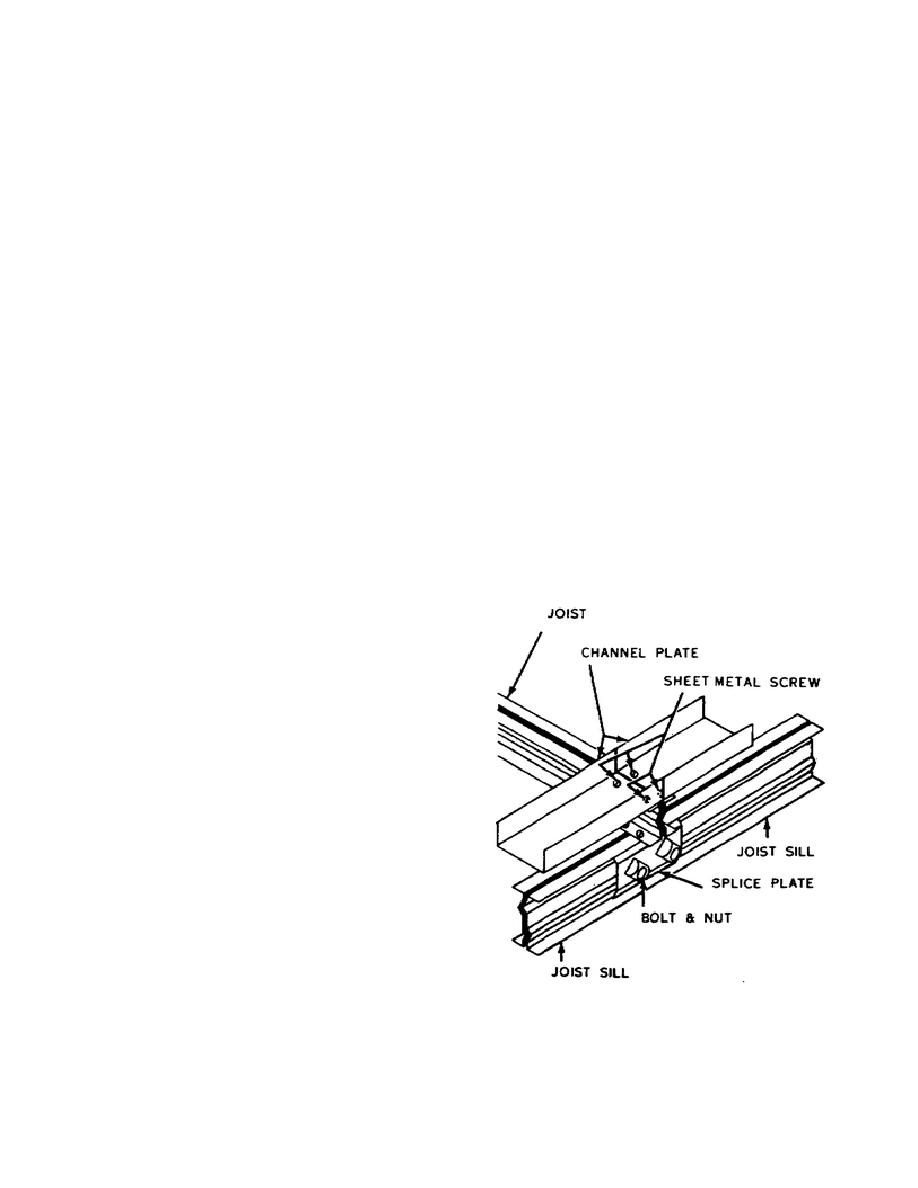

joist sill (its function) in metal construction. Joists spaced

roof. Don't walk around on the roof any more than is

absolutely necessary. Instead, you should locate the leak

2 feet on-center are placed on, and perpendicular to, the

by entering the attic and checking for water marks. Then

joist sills, as shown in figure 31. A U-shaped channel

go on the roof and make the repair. Use a 1 x 12 for a

plate fastened to

walkway and avoid walking between the rafters. The

wide spacing of the rafters allows the decking to sag when

you walk on it Of course, old, brittle roofing may be

broken beyond repair, and the only feasible way to fix

leaks may be to put on new rolled roofing.

4-25. Most repair work on the framed prefab building

is similar to the repair work on a standard frame structure.

Just keep in mind that this is a light frame building.

Repairs to the frame usually consist of nailing splices

beside the faulty member rather than attempting to replace

the frame.

4-26. Now that we have discussed wooden prefab

buildings, let's see how prefabricated metal buildings are

assembled and repaired.

5. Prefabricated Metal Buildings

5-1. The prefabricated metal buildings in use on some

military installations are constructed of many different

types of metal. However, galvanized sheet metal and

aluminum are the most common metals used in prefab

buildings. Most metal prefabs are referred to as portable

buildings, because they are easy to disassemble and

Figure 31. Sill and joist assembly.

18

Previous Page

Previous Page