vertical cut that will be framed against the platform.

by the thickness of a tread - in this case 1 1/2

inches.

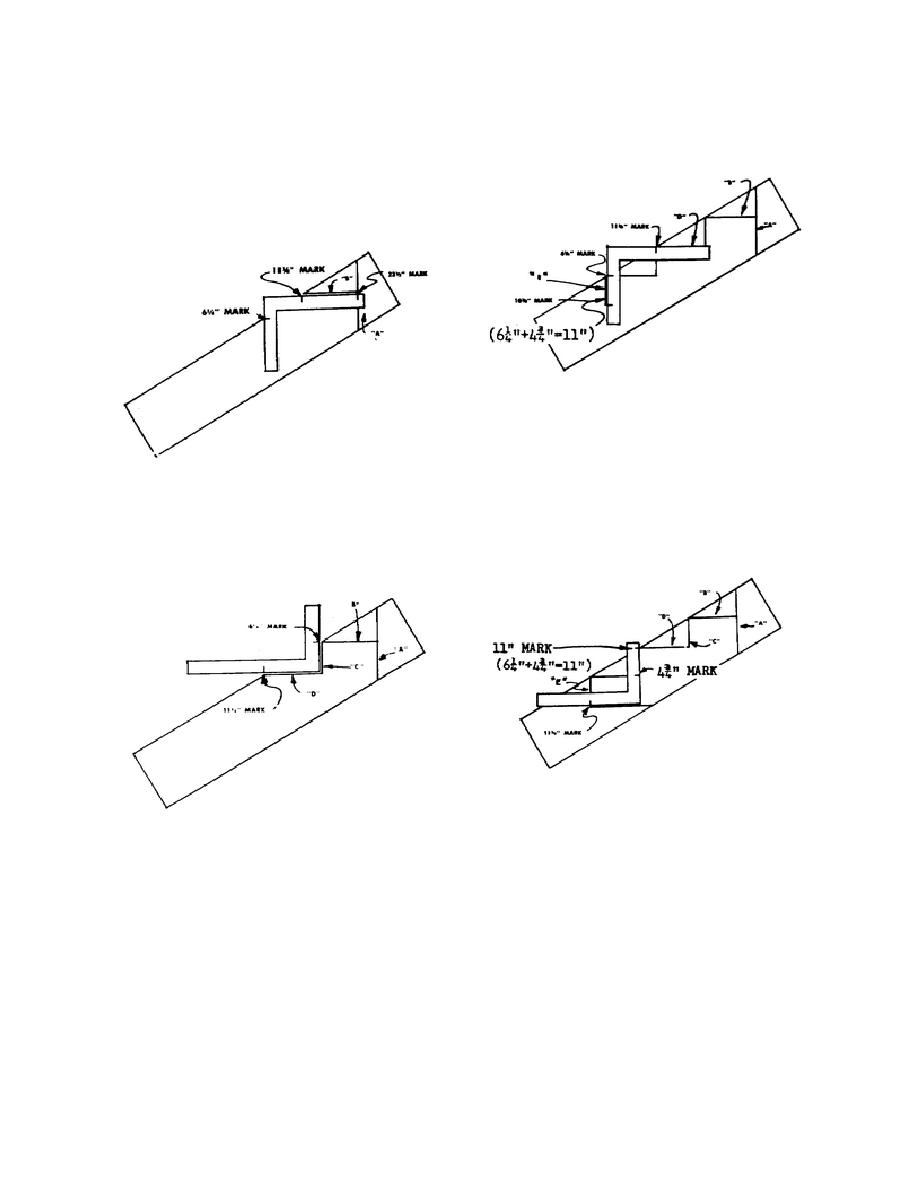

(2) The next step is to mark off the top

tread. Using again a rise of 6 1/4 inches but with a

run of 2 times 11 3/4 or 23 1/2 inches, lay off the top

tread as shown in figure 3-16. By drawing line B 11

3/4 inches long, the top tread has been marked.

Figure 3-18. Layout of bottom riser.

(5) The final step is to mark the

horizontal cut at the lower end of the stringer. It is

located by drawing a horizontal line through the

lower end of line E. Figure 3-19 shows the

Figure 3-16. First tread cut.

placement of the framing square. When this line has

(3) To mark the top riser of the stringer

been drawn, the layout of the stair stringer is

and the second tread from the top, use again a 6 1/4-

complete. The stringer can then be cut out and used

inch rise and 11 3/4-inch run and mark them in the

as a pattern for other stringers of the same stairs,

manner shown in figure 3-17. Line C is the riser and

either conventional or built-up.

D the tread.

Figure 3-19. Marking the bottom horizontal cut.

c. The triangular blocks cut out in cutting

Figure 3-17. Riser and tread layout.

conventional stringers from 2 x 12 or similar stock

can be used to make built-up stringers. The blocks

(4) The next tread and riser are marked

are toenailed to a piece of 2 x 4 stock as shown in

in exactly the same way as C and D. When this is

figure 3-20. The vertical cut (fig. 3-15) and the

completed, the only marks still to be laid off are the

bottom cut (fig. 3-19) are obtained by using an

bottom riser and the horizontal cut at the bottom of

already cut conventional stringer as a pattern, adding

the stringer. Figure 3-18 illustrates how the bottom

pairs of scabs if necessary to fill out the

riser is marked. It should be noted again that the

bottom riser is always shorter than the other risers

3-11

Previous Page

Previous Page