_________________________________________________________________ Semiconductor Diodes

CONSTRUCTION

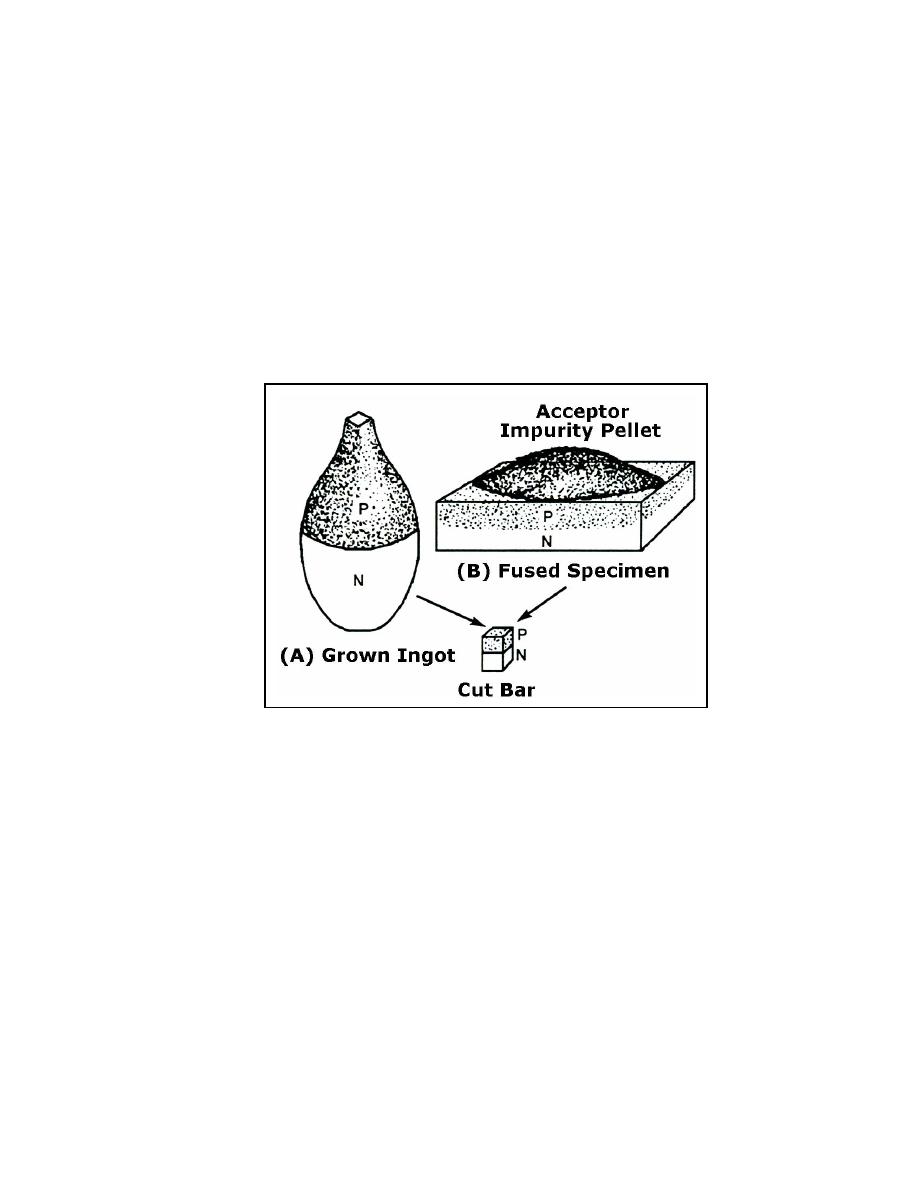

1-58. Merely pressing together a section of P and N material is not sufficient to produce

a rectifying junction. To form a proper PN junction, the semiconductor should be in one

piece, but divided into a P-type impurity region and an N-type impurity region. This can be

done in different ways. One way is to mix P-type and N-type impurities into a single

crystal during the manufacturing process. Doing this causes a P-region to grow over part of

a semiconductor's length and an N-region to grow over the other part. This is called a

GROWN junction (see Figure 1-13, view (A)). Another way to produce a PN junction is to

melt one type of impurity into a semiconductor of the opposite type impurity. For example,

a pellet of acceptor impurity is placed on a wafer of N-type germanium and heated. Under

controlled temperature conditions, the acceptor impurity fuses into the wafer to form a P-

region within it (see Figure 1-13, view (B)). This type of junction is known as an ALLOY

or FUSED-ALLOY junction. This is also one of the most commonly used junctions.

Figure 1-13. Grown and Fused PN Junctions From Which Bars are Cut

1-59. Figure 1-14 shows a POINT-CONTACT type of construction. It consists of a fine

metal wire (called a cat whisker) that makes contact with a small area on the surface of a

N-type semiconductor (view (A)). The PN union is formed in this process by quickly

applying a high-surge current to the wire and the N-type semiconductor. The heat

generated by this current converts the material nearest the point of contact to a P-type

material (view (B)).

1-60. Still another process is to heat a section of semiconductor material to near melting

and then diffuse impurity atoms into a surface layer. Regardless of the process, the object

is to have a perfect bond everywhere along the union (interface) between the P and N

materials. Proper contact along the union is important because the union (junction or

interface) is the rectifying agent in the diode.

23 June 2005

TC 9-62

1-17

Previous Page

Previous Page