layer of insulation or it may be some other type of

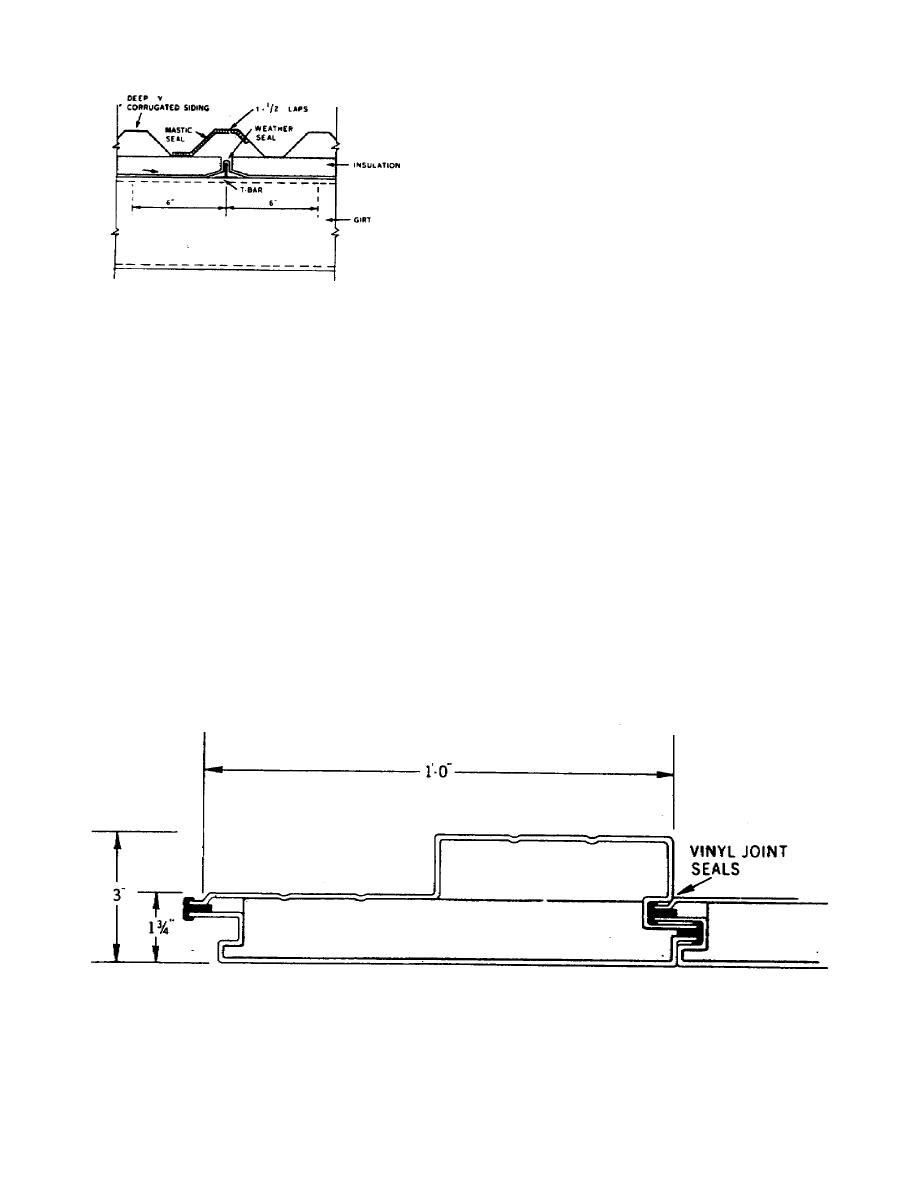

material. Figure 38 shows two insulated panels joined

together with a vertical joint.

With this type of

installation, the T-bar is secured to the wall girts, and the

metal weather seal is placed over the T-bar to provide a

durable, moisture-proof joint. The insulation of the first

panel butts against the weather seal, and the metal siding

laps over the joint. The next panel has the insulation

butted against the weather seal, and the metal siding laps

over the previous sheet to form a lap joint of 1 1/2 laps.

A mastic seal is applied to the area of the lap before the

second panel is installed. This mastic seal is permanent

and should never have to be replaced, except when the

panel is replaced or the building in disassembled and

Figure 38. Deep V-wall panel.

relocated.

5-18. Another type of ribbed wall panel that has an

and the siding. Angles also fit between the Z-shaped wall

insulated core is shown in figure 39. This panel has vinyl

girts to provide a fastening surface for the window frame.

joint seals inserted along the edges. The vertical edges fit

5-16. Notice the brace rods in figure 37. These brace

together as do those of tongue and groove boards to

rods are used to square the end bays of the building.

make a weatherproof joint.

The brace rods in the wall run diagonally from the top of

5-19. The lap joint and the vinyl seal joint are the two

one column to the bottom of the adjoining column. The

common methods used to make weatherproof vertical

rods pass through slots in the columns, and a bevel

joints in exterior walls. The mastic seal used in the lap

washer, flat washer, and nut are used on the ends of the

joint of insulated panels is also used with sheetmetal

rods. Turnbuckles are used at an intermediate point in

siding and roofing. The mastic comes in strips with a

the rod to provide for adjustment. The turnbuckle has a

moisture-proof paper backing that looks like masking

right-hand thread in one end and a left-hand thread in

tape. The strips are rolled like tape for easy handling.

the other so that it can be tightened or loosened on each

You unroll the tape and apply the mastic and backing on

section of the rod at the same time. Adjustments may

the joint area. Leave the paper backing on the mastic

also be made by tightening or loosening the nuts on the

until you are ready to install the next panel. Just peel the

end of the rods. When you tighten one rod, you must

paper off to expose the clean layer of mastic when you

loosen the one that crosses it to provide for a shift in the

are ready to cover the joint. This mastic is also required

framing. The brace rods between the roof beams serve

in the horizontal joints of roof panels to prevent water

to hold the bay square and must be considered if you

from being blown under the top panel.

adjust the brace rods enough to cause a shift in the

5-20. When horizontal joints are required in

frame.

5-17. Wall and roof coverings.

The metal wall

covering may be a panel that contains a

Figure 39. Ribbed wall panel.

22

Previous Page

Previous Page