corrosion of the other metal. This is the so-called

galvanic action or electrolysis that occurs when metals of

different position in the electromotive series are in direct

contact in the presence of an electrolyte. The common

metals used in construction are listed in the electromotive

series in the following order: 1-aluminum, 2-zinc, 3-iron

4-tin, 5-lead, 6-copper. When any two metals in this list

are in contact in the presence of an electrolyte, the one

with the lowest number is corroded. Also, the farther

the separation in the list, the greater the corrosion will be.

Thus with iron and copper contact in the presence of

water, the iron would be corroded more than lead in

contact with copper under similar any condition. Any

means that separates dissimilar metals will protect against

this action.

5-27. Perhaps you are beginning to wonder how

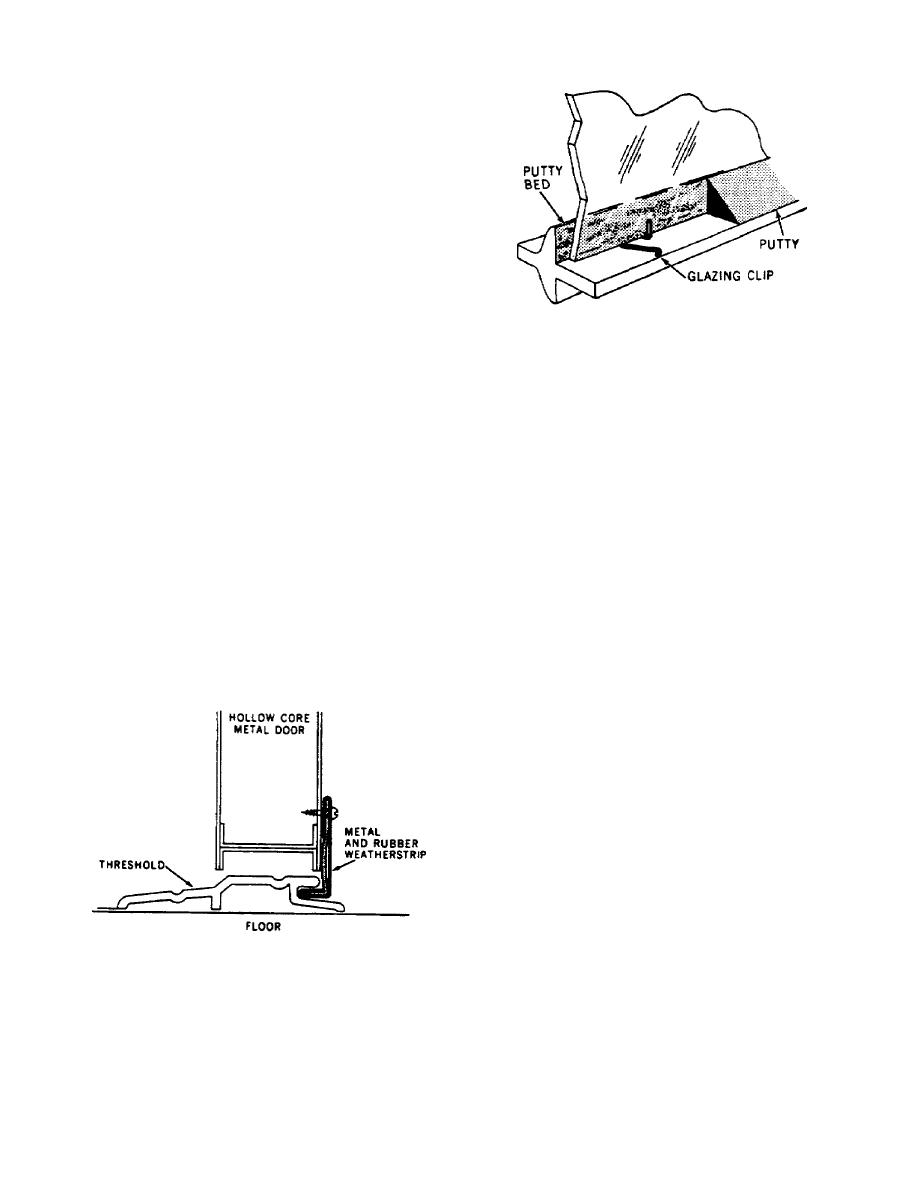

Figure 44. Glazing metal sash.

dissimilar metals can be used in layers as a single sheet of

metal. Let's take lead-coated copper as an example. The

like a flush door and may have either a hollow or

lead coating on the copper is of a lower number value in

insulated core.

the electromotive series and is affected by the corrosion

5-30. Metal doors seldom need repairing and

while the copper is being protected from corrosion. Also,

maintenance usually consists of tightening the bolts that

the two metals are consecutive (5 and 6) in the series,

hold the lock in place, or tightening or replacing screws in

and a minimum amount of corrosion is anticipated. The

the hinges and weatherstrip. Occupants usually correct

purpose of the lead coating is to protect the copper; in

the problem of loose screws and bolts, but you will

this case, it protects it in two ways, physically and

probably be called on to supply new or larger screws.

chemically.

When retightening of screws is required at frequent

5-28. Doors and windows. We have discussed the

intervals, you should substitute a screw that is one size

location and fastening of door post and window angles.

larger than the old one or relocate the hinge and make

Now let's look at the main units.

new screw holes. The weatherstrip on the jamb causes

5-29. Metal doors are preferred for prefabricated metal

very little trouble, but the strip along the bottom of the

buildings. There are two types of these doors. One type

door may get damaged or become loose. This threshold

has an angle iron, steel, or aluminum frame and a single

strip extends beyond the lower edge of the door and

metal covering that serves as the exterior surface. The

hooks into a groove in the threshold as shown in figure

frame is exposed on the inside of the building. The

43. Make sure that the strip is adjusted so that it fits into

other type of metal door has a metal frame with a metal

the groove. This type of threshold and weatherstrip is

covering on each side. This door is built

common in exterior doors that swing over a concrete

floor.

5-31. Window maintenance consist of tightening the

mounting screws in the frame, side panels, and the

U-shaped drip channel (gutter). Replacing glass in a

metal sash is a little different than working with a wood

sash. When you remove the old putty from the sash, you

must locate and save the metal glazing clips. Look at the

glazing clip shown in figure 44. This clip fits between

the edge of the glass and the frame. One end of the clip

fits into a hole in the frame, and the other end hooks

over the edge of the glass. Allow for the thickness of

these clips when you cut the new glass. Place a bed of

putty on the frame and press the new glass gently against

it. Use a screwdriver to install the glazing clips. The

clips will hold the glass in place while you are applying

the beveled layer of putty around the edge of the glass.

Figure 43. Weatherstrip installation.

24

Previous Page

Previous Page