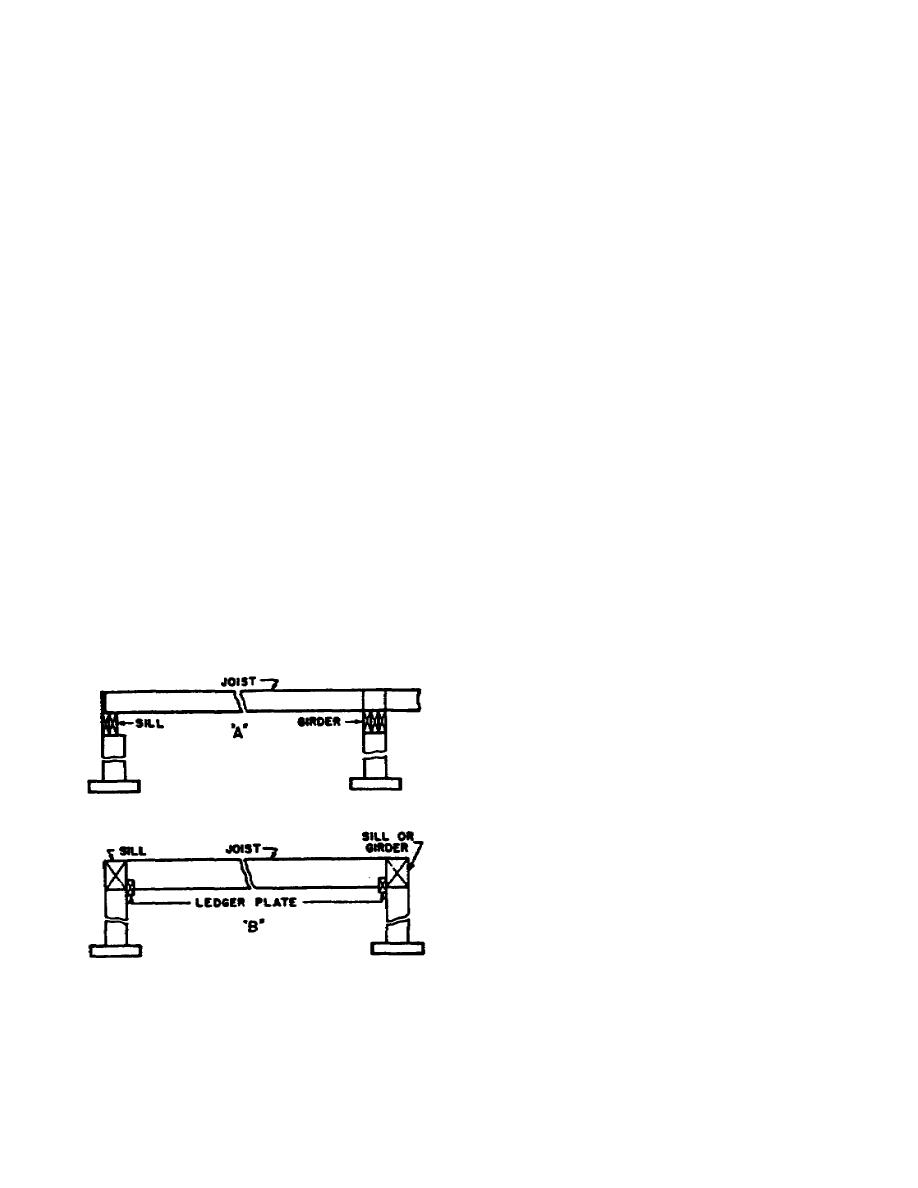

Figure 46. Joist contruction

carry only the weight of cargo. For this reason, we will

discuss the different types of foundations and how they

you should use a heavier joist rather than narrow the

should be constructed to adequately support the intended

spacing. When joists are being placed, make sure that

loads.

the greatest bearing surface is used. In other words, place

7-3. Foundations.

Normally, loading dock

them with the crown edge up.

foundations are constructed of either wood and masonry

Placing the crown edge up will tend to counteract the

piers or columns. These columns or piers must be spaced

bending force imposed on the joist. After each joist is

according to the weight they are to carry. In most cases,

placed, it should be secured. as indicated in figure 46.

7-8. Bracing.

however, they are spaced from 6 to 10 feet apart.

If we expect loading docks to

7-4. If the earth on which the foundation is to rest

adequately support the loads placed up on them and to

has low supporting strength. of if the loads are expected

withstand the abuse from vehicles, we must reinforce

to be extremely heavy, the foundation should be

them with some type of bracing.

constructed as a solid, reinforced concrete wall.

This bracing must be properly designed and placed to

7-5. Sills. Sills consist of single heavy timbers or

give the support desired.

buildups of two or more timbers. Sill sizes will be

7-9. If wooden piers are used as a foundation, they

determined by the intended loads to be carried and the

should be braced to each other with diagonal braces, as

distance between piers. Consequently, sills are used with

shown 'in figure 45. If wooden girders are used in the

pier type foundations and are placed directly on the pier.

platform construction, a truss brace should be placed

If sills are correctly placed, they will surround the

under each girder.

If the platform is to support

perimeter of the dock. After the sills are tied to the

extremely heavy loads.

piers, girders (if needed) are placed.

bracing should be secured with bolts. On the other hand,

7-6. Girders. Girders are used as interior foundation

light load carrying platform bracing may be secured with

walls to support the inner ends of floor joists. However,

spikes. No matter what method you use to secure the

they will not be needed if joists safely span the distance

bracing, make sure that the materials used have good

from sill to sill. If girders are not used, joists should be

bearing qualities.

7-10. Decking. Decking. or flooring. used on loading

placed directly on the sills.

7-7. Joists. Joists are the lighter pieces which make

docks should be at least 3 inches thick and laid

up the body of the floor fame. We don't mean that they

perpendicular to the joists. All joints must be staggered

are actually light in weight but that they are light in

and joined directly over a joist. After decking has been

comparison with the other framing members. Joists are

correctly fitted and placed, it should be secured with large

usually 3 inches thick, but thicknesses will vary to suit the

spikes.

construction details. They are usually spaced from 16 to

7-11. After the platform has been erected and properly

24 inches on-center. However, if this spacing is too wide

floored, it should be protected from unnecessary bumps

to support the intended load.

and scrapes. This protection is supplied by fender boards.

7-12. Fender boards. Fender boards are heavy timbers

placed in front of the loading dock to protect it from

vehicle contact damage. They are secured to the sills

with spikes or bolts, depending upon the size of the

timbers. If adequately placed, fender boards form a solid,

continuous row of timbers.

7-13. General Maintenance Problems. Your job is

not complete when you finish the construction of the

warehouse loading dock.

There is a continual

maintenance problem, and it is your job to perform this

maintenance. Aside from original flaws in materials,

structural sealing, weathering, and normal wear and tear,

deterioration presents our most extensive maintenance

problem. Deterioration is cause by decay (fungi action),

rust (chemical action), and insects (termites and marine

borers).

7-14. Decay and its prevention. Unpainted or untreated

wooden members are more subject to decay than any of

the other construction materials. Warm, humid climates

or seasonal periods

27

Previous Page

Previous Page