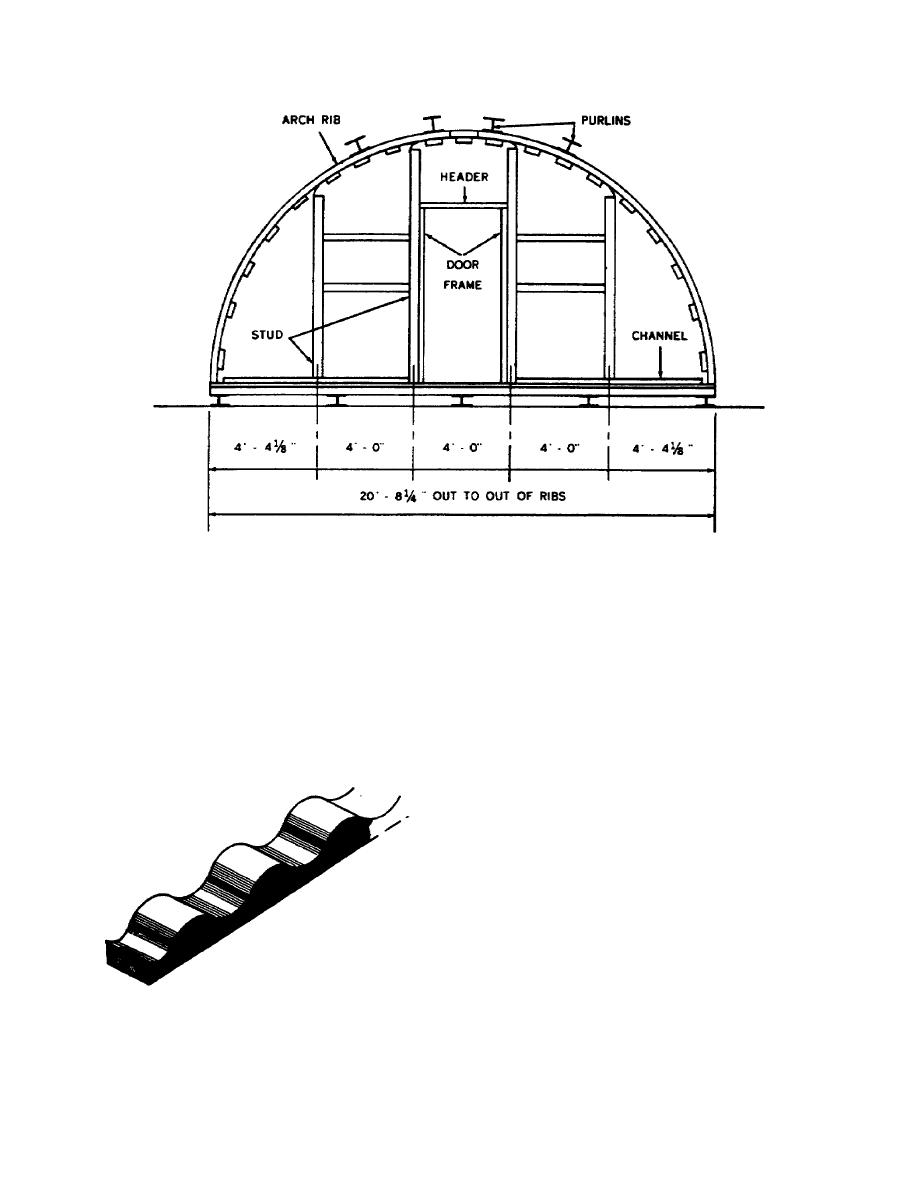

Figure 34. End wall framing.

36 shows the complete assembly as it appears at the

ing that has been put up to support one special function.

bottom of the wall. Be very careful when you remove an

The light-steel frame building is made in different sizes,

inside panel. If you should loosen the adjoining panels,

with different types of light-steel frames. The frame

they may spring from the ribs and you will have more

shown in figure 37 is similar to the frames used for

than a handful of panels at one time. Always have

buildings of 20-to 50-foot width, with bays 12, 16, or 20

another worker with you when you remove the panels or

feet long, and exterior walls that are 10, 12, or 14 feet

corrugated sheet metal, because it is a two-man job.

high. A bay is the distance between columns along the

side walls. A bay is the basic assembly, and a building

5-10. Light-Steel Frame Buildings. The light steel

consists of one or more bays. There is no limit to the

frame building is a common building or many bases. It

number of bays that can be placed end-to-end to form a

is usually a special-purpose build-

building. The frame shown in figure 37 is often referred

to as open-bay construction, because the are no supports

needed in the bay. The area between the side walls is

open, unobstructed space.

5-11. Framing. The end wall frame is assembled of

prefabricated parts. Each piece of metal is shaped and

drilled for assembly before it leaves the factor. The

frame is set up on a concrete foundation or slab. Anchor

bolts are placed in the concrete to provide solid fasteners

far the columns. Because the column is a vertical

member, a channel type base plate is used to secure the

column in place. The anchor bolts hold the base plate,

and the base plate is bolted to the base of the column

Figure 35. Rubber seal.

20

Previous Page

Previous Page