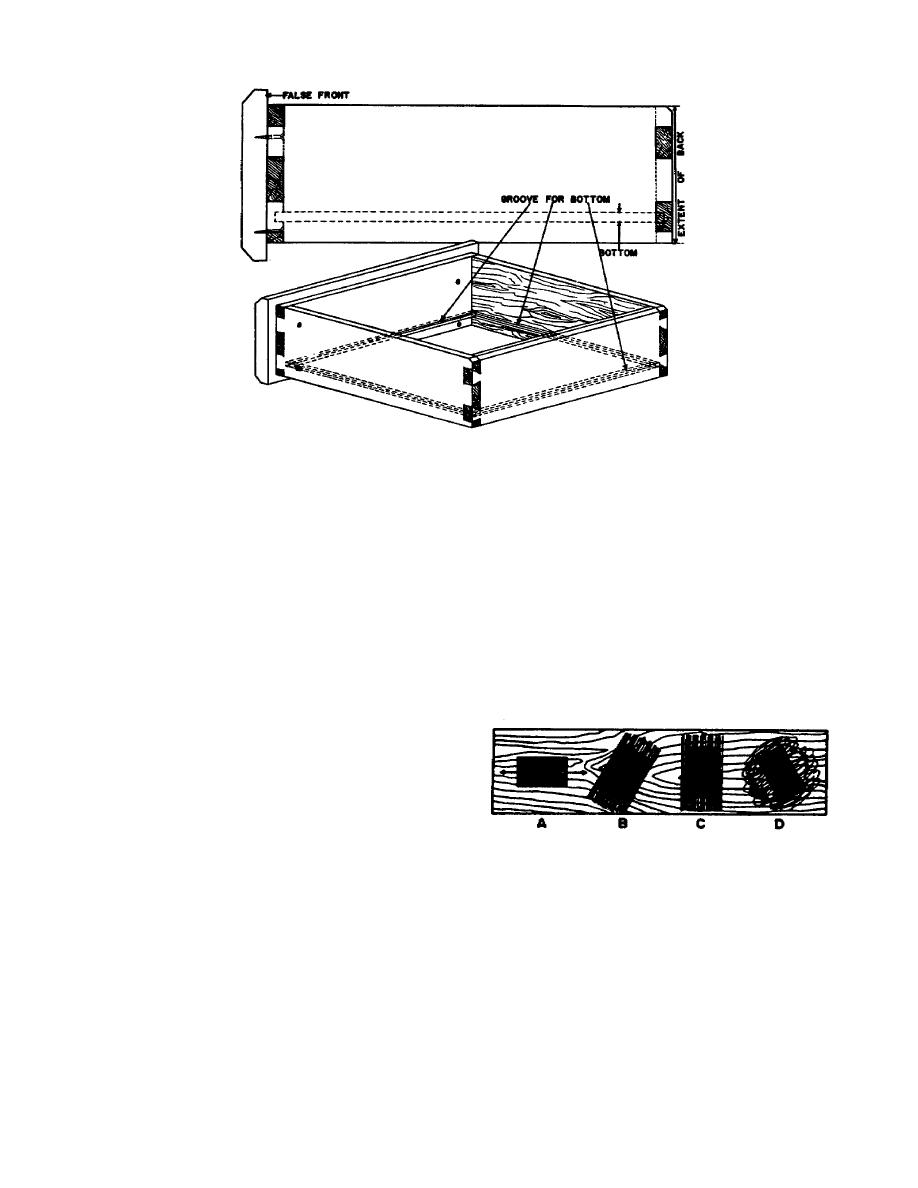

Figure 25. Detail for drawer construction.

should have a pleasing grain, and if more than one

motion when sanding flat surfaces; instead, use long,

drawer is used, the grain characteristics should be similar

even strokes.

on each front. This is true for a clear finish but is not

3-26. If parts of the article you are making have

important if your articles will be painted. Your drawing

irregular curves, sand them on the spindle part of the disk

may call for a false front on a drawer (see fig. 25); if so,

and spindle sander; however, if a sander is not available

the material should be carefully selected and milled to the

and the curves are long, sand by hand with a block. The

dimensions specified.

block guards against rounding the edges. Sand inside

3-24. We have discussed the various parts you will

curves by hand, using a stick with a rounded surface.

have to mill in any one of your projects. Before you

(See fig. 27.)

begin to assemble any of these pans into units, sand each

3-27. For all lathe turnings, such as the posts for

part to remove toolmarks or other blemishes. The

tables, stools, or the rungs of chairs, make sure each

greater portion of the sanding should be completed

turning is sanded to a smooth surface before you begin

before the parts are assembled, so that after an article is

any assembly work.

assembled, it needs only touchup sanding to have it ready

for finishing.

3-25. Always sand with the grain-never across it-or

you will mar the surface of the wood with scratches.

Figure 26, A, illustrates the correct direction the sand

block should move when you are sanding by hand. The

other three parts of figure 26 show incorrect use of the

sand

Figure 26. Direction for sand block.

12

Previous Page

Previous Page