for opening. When you fit doors, remove the waste

equally from all stiles and rails so that their width will

stay balanced.

3-21. Flush doors for most cabinets are solid and are

cut to the specified dimensions shown on your drawing-

making sure the tops, bottoms, and hinged sides are true.

3-22. Regardless of the type of door, the material

selected must be straight and have good grain

characteristics. If the material for the doors must be

glued, match the grain characteristics. When you mill

out material for more than one door-especially for double

doors-do it all at one time.

3-23. If the article you make has drawers., there will

usually be a detailed drawing of the drawer construction

along with your blueprint. Check your plan for the

thickness and width of the sides, front, and back of each

drawer, and then mill the stock to these dimensions.

When you start cutting the joints for a drawer, mark the

pieces "sides," "fronts," and "backs," with the side pieces

marked "lefts" and "rights." The reason for this is that

bottoms of most drawers are inserted into grooves cut on

the inside of each side, front, and back piece of drawer.

This is clearly illustrated in figure 25. Plywood used for

the bottom of the drawers should have the good side up

so that it can be seen when the drawer is opened. It is

essential to have all material cut square if the drawer is to

fit well. Wood used for side and back pieces can have

slight defects; however, they must be placed so that they

cannot be seen from the inside when the drawer is open.

Material for the drawer fronts

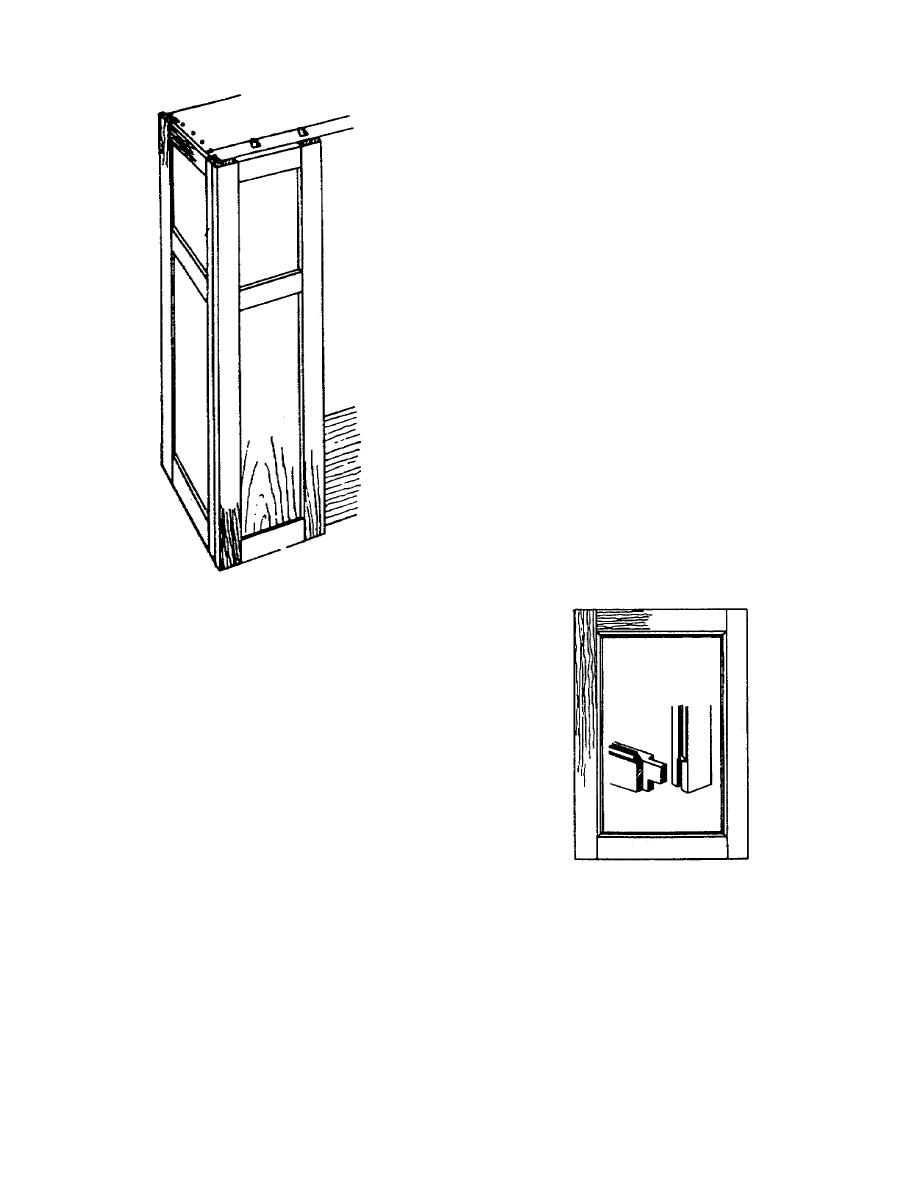

Figure 23. Panels for frame construction.

panels square, remove the rough edges, and be sure that

the groove is large enough to receive the panel.

3-20. Doors used on cabinets and furniture can be

classified as paneled or flush. Flush doors are usually

made solid or with a frame covered with plywood. The

frame for panel doors can be mortised and tenoned,

doweled, lapped, or mitered. Your drawing will give you

these details. The material for the framework is milled

to the dimensions specified on your drawing. After the

milling process, the rails and stiles are cut to length. The

material for the framework is milled to the dimensions

specified on your drawing. After the milling process, the

rails and stiles are cut to length. The joint to be used is

made along with a groove in each rail and stile for the

panel. Sometimes a molding is cut on the inside edge of

the frame near the panel. (See fig. 24.) Before cutting

Figure 24. Molding on paneled door.

the molding, select the best side of the frame to show

when the doors are closed. If any joint other than a

miter joint is used, the molding must be mitered, as

shown in figure 24. The hinged side of the door should

be planed true with the top and bottom, and the lock side

should have a slight angle to provide clearance

11

Previous Page

Previous Page