marily used for the rear corners of drawers. The milled

corner joint, shown in figure 16, C, consists of two

members with milled grooves that are fisted together.

This joint is used for the front corners of drawers,

because it will resist the pull exerted on the front of the

drawer.

2-24. By now you should have a good idea of both the

wood used and the types of joints required to construct

an article. With this information firmly in mind, let's

take a look at the recommended procedures for

constructing a wooden article.

2-25. Butt joints. The butt joint consists of two

members that are fastened together end to end without

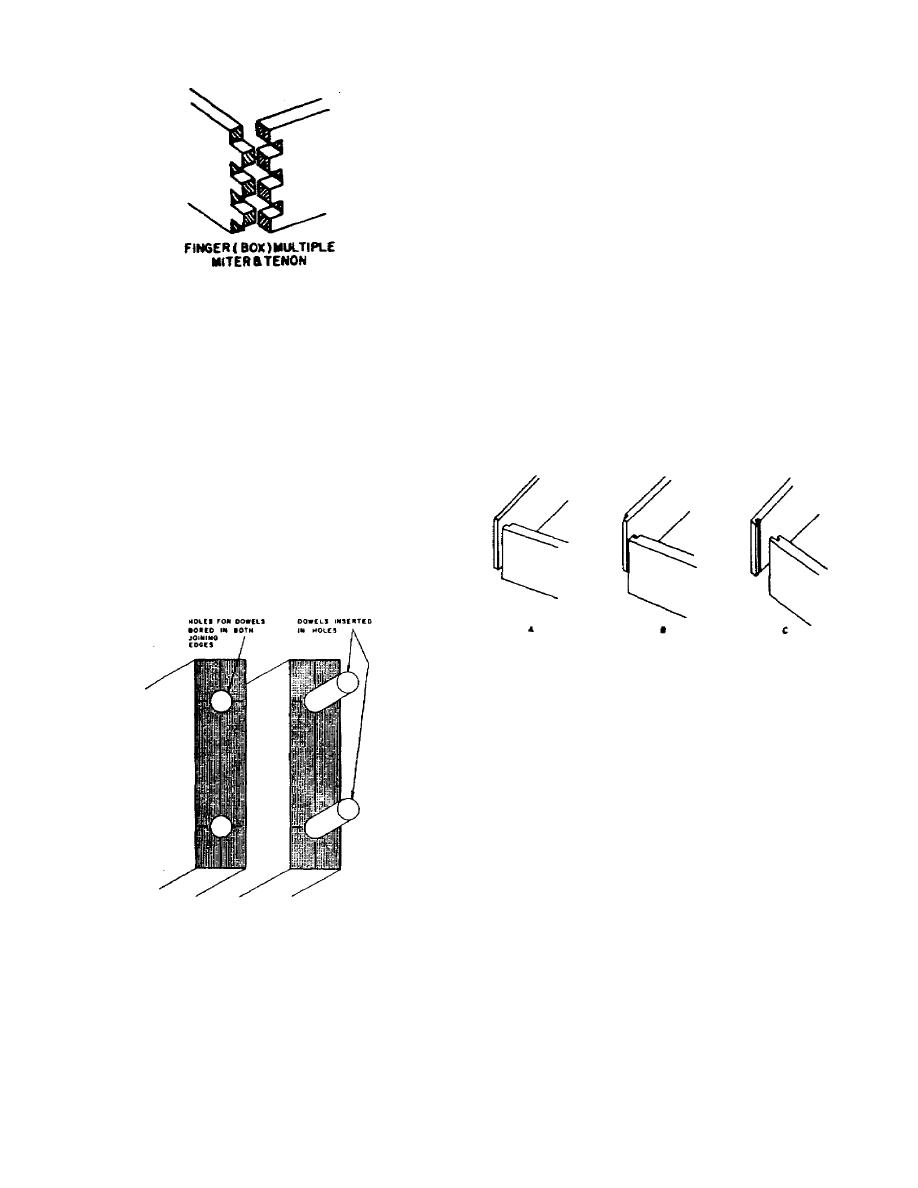

Figure 14. Finger or box dovetail joints.

overlap. This joint is often strengthened with a strap or

straps.

cut the dowels one-eighth inch shorter than the

combined depths of the holes and to point the end with

3. Constructing Wooden Articles

coarse sandpaper or a knife. Dowel joints are always

glued and are often used as a substitute for mortise and

3-1. You can probably remember the furniture in

tenon joints. To allow air and excess glue to escape, cut

your grandmother's home when you were a youngster.

a channel, or spiral, the full length of each dowel.

Today, your grandmother's furniture would be considered

2-23. Corner joints. Corner joints, other than the

as old fashioned as that

mitered, butted, doweled, or dovetailed types, are used

extensively in the construction of drawers for furniture

and cabinets. A corner joint is shown figure 16. A.

One member of the joint is rabbeted, with the other

member fitted into the rabbet and fastened with glue,

nails, screws, or a combination of glue and a metal

fastener. The box corner joint, shown in figure 16. B.

consists of two members, one dadoed and the other

rabbeted to fit the dado. This corner joint is pri-

Figure 16. Corner joints.

of her grandparents, because designs and styles continue

to change. Modern-day furniture designers try to create

furniture that will give us convenience, comfort, and

beauty.

3-2. Along with the many style changes, mass

production methods and new materials have changed

cabinet construction procedures. However, the basic

forms of construction remain relatively the same as they

were when our so-called antiques were made. Today,

however, there are more "built-ins" in the form of

cabinets, dressing tables, and workcounters.

3-3. This section will provide you with the knowledge

you will require to construct and repair cabinets; it will

Figure 15. Doweled joints.

also cover types of construction, which include frame,

stool, and box. The procedure used in the selection of

materials for the items covered in this section are also

extremely important and should be followed as closely as

possible.

3-4. The last two major topics in this section are the

assembling of parts into complete units

7

Previous Page

Previous Page