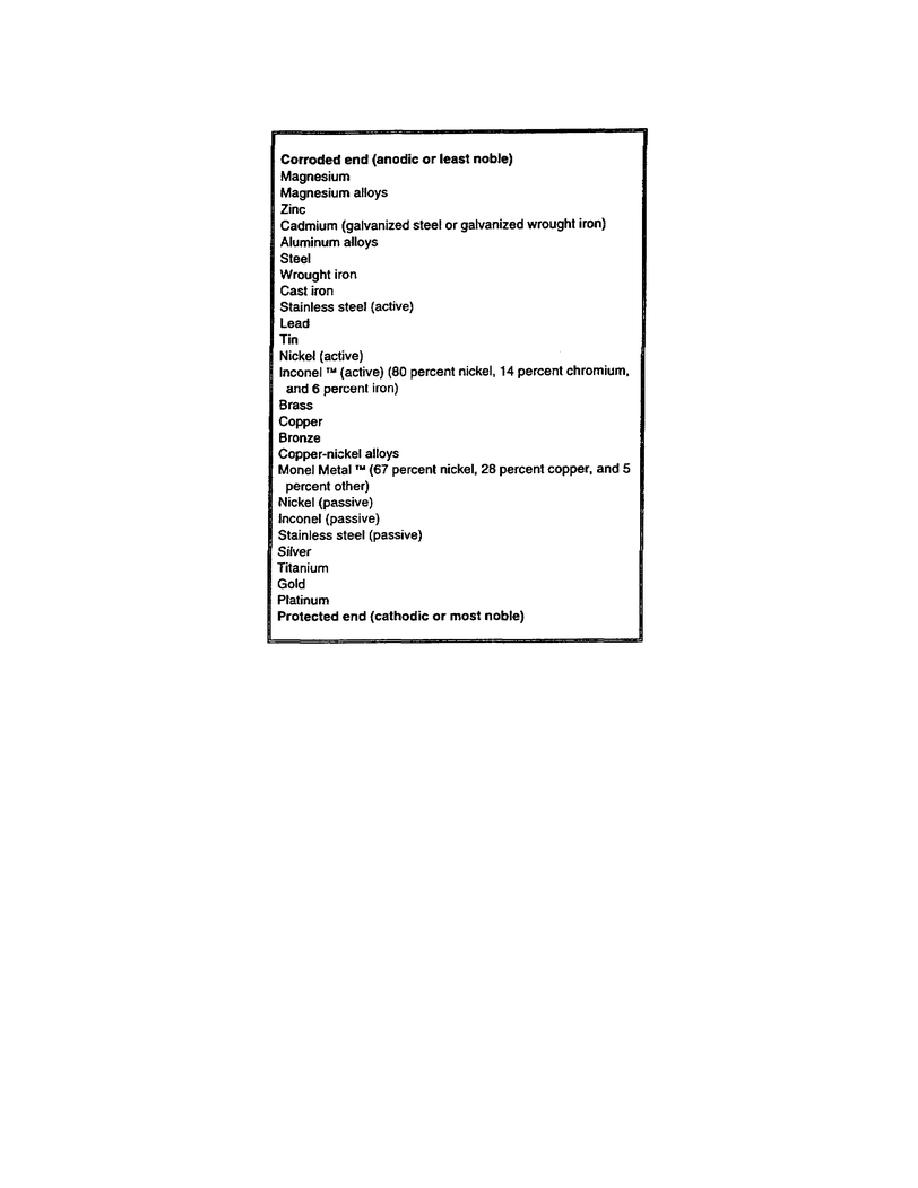

Table 5-2. Metal and alloy galvonic series

d. Stress Cracking.

(1) Stress cracking is caused by the distortion of a metal's grain structure. Distortions are

induced when metals are punched, cold-riveted, shrink-fitted, or otherwise distorted after hot-finishing.

Distortion is also caused by the metal bending or twisting. This bending or twisting may be a

continuous stressed condition or it may be an alternating stressed and unstressed condition. Stress

corrosion is due primarily to the fracture of a metal's surface, film, or coating. The corrosion process is

accelerated by fractures or tiny cracks that permit moisture to enter.

(2) After surface cleaning, stress cracks are usually visible at the bottom of corrosion pits.

Corrosion pits may form before or simultaneously with any stress condition. The pitting rate is more

rapid with simultaneous stress. In the second stage, a stress crack at the pit base develops rapidly and

gradually penetrates the section until a fracture occurs.

(3) A good example of stress corrosion is the use of cold-worked rivets to join steel sheets

used in storage tank construction. The rivets carry an internal strainthe deformation of the rivet shank

that makes them anodic (dissimilar metals) to the steel. The stressed area forms the anode to the

adjacent unstressed parts. Since the rivets are

5-7

EN0562

Previous Page

Previous Page