Lesson 1/Learning Event 3

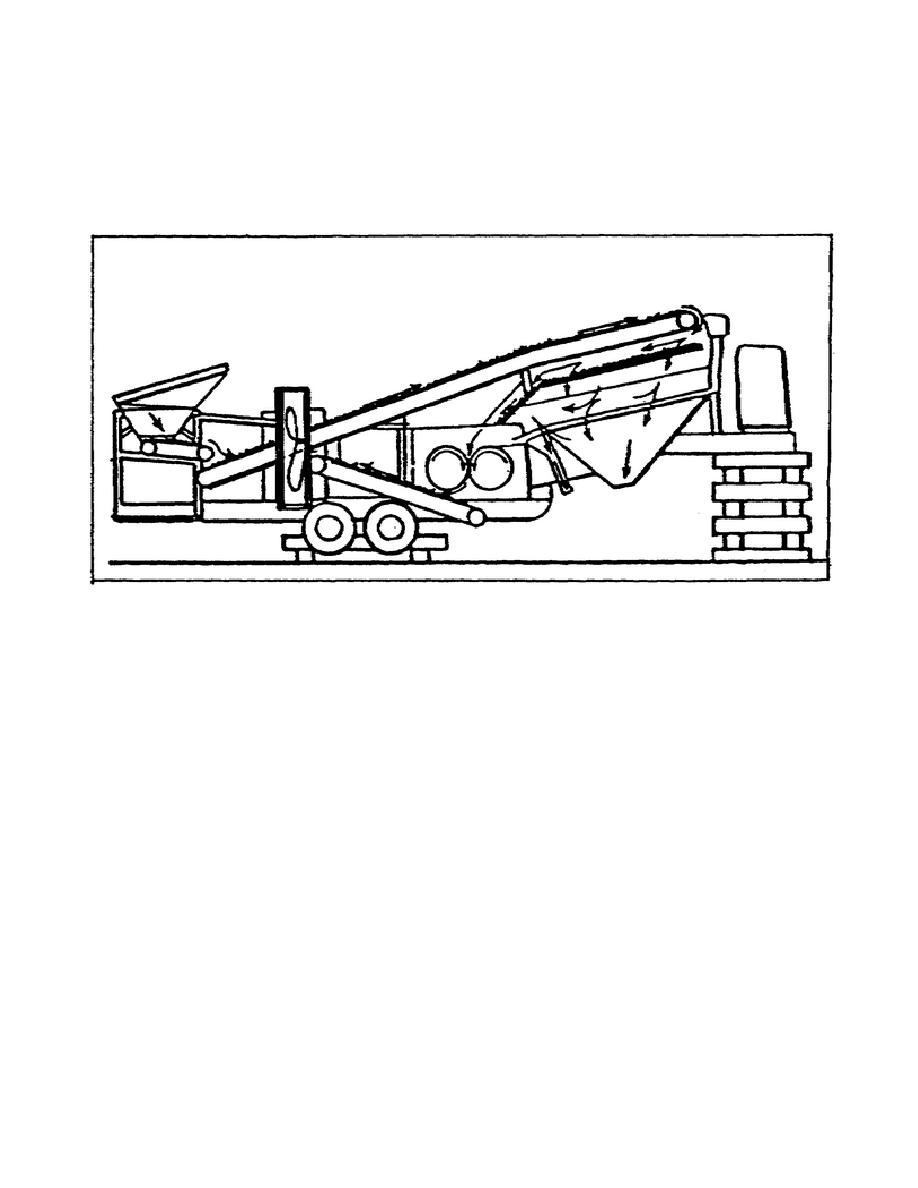

The secondary unit (Figure 12) is ordinarily used to process the product of the jaw crusher. Any further size

reduction required is accomplished in the dual roller crusher, and the crushed stone is separated into product size

ranges as required by specifications. The secondary unit of Set No. 1 has special features which also make it

ideally suited to use all by itself in gravel deposits. The 75-tph plant uses a "closed circuit" crushing system, as

does the 35-tph plant previously discussed.

FIGURE 12. MATERIAL FLOW THROUGH THE SECONDARY

UNIT OF A 75-tph CRUSHING AND SCREENING PLANT, SET NO. 1

Production Considerations. The jaw crusher will produce in the range of 55 to 185 tons per hour, depending

upon the product setting and the toughness of the material being crushed. The maximum product setting is 5

inches and the minimum setting is 1-1/2 inches.

The secondary unit has a wide range of production capability. The actual rate of production in tons per hour is

usually determined by the screening capacity of the screens being used, although in some cases the rate may be

limited by the capacity of the dual roll crusher.

The use of components within Set No. 1 is entirely flexible. Equipment is selected, arranged, and set up in such a

way as to transform the available raw material into a usable product in the most practical and effective manner.

Equipment, Set No. 2

Function and Operation. Equipment Set No. 2 is composed of a washing and screening unit and an auxiliary

screening unit. It is high capacity equipment normally found in Engineer Construction Support Units. It is

commonly

21

Previous Page

Previous Page