Lesson 1/Learning Event 3

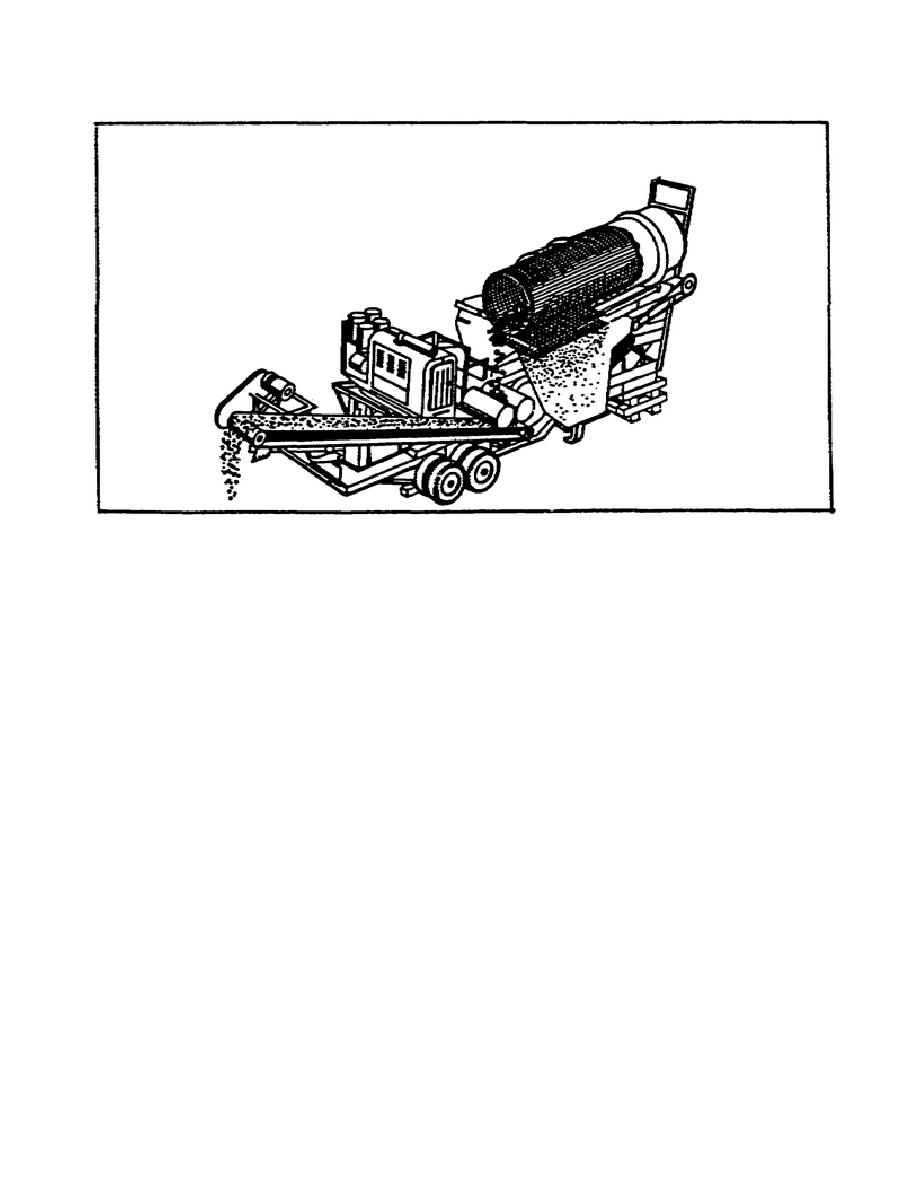

FIGURE 16. MATERIAL FLOW THROUGH THE SECOND

INTERMEDIATE UNIT OF A 225-tph CRUSHING

AND SCREENING PLANT

In addition to the major items described above, the 225-tph plant includes other items of equipment

which have been explained in detail earlier in this lesson. This equipment includes a sand dehydrator, a log

washer, a reciprocating plate feeder, and four conveyors.

Production Considerations. The jaw crusher, or primary unit, will produce between 200 and 400 tons per hour,

depending upon the product setting and the toughness of the material being crushed. The maximum product

setting is 8 inches and the minimum setting is 4 inches.

The first intermediate unit is capable of receiving gravel deposit materials or crushed rock up to 7 inches in size

and reducing it. The maximum product setting is 4 inches and the minimum setting is 1-1/2 inches. This unit has

a wide range of production capability. The actual rate of production is normally determined by screening capacity

of the size screens being used, although in some cases the rate may be limited to the reduction capacity of the dual

rolls.

The washing plant is capable of receiving gravel source material or crushed rock up to 4 inches in size,

accomplishing further size reduction, and producing up to two size ranges of washed aggregate and clean, washed

sand. It has a wide range of output production rates depending upon the screen sizes being used and upon the roll

crusher product setting.

The second intermediate unit is capable of accomplishing a fourth stage of rock size reduction, and will produce

up to one size range of crushed stone product and sand. It has a wide range of output production rates depending

26

Previous Page

Previous Page