Lesson 1/learning Event 3

crusher is set up at the source of material to be crushed. It is important that it be jacked up or cribbed so that the

rubber tires are off the ground, and level. It may be fed by some combination of headwall, chutes, and small

materials handling equipment. However, in many circumstances, feeding by hand labor will prove to be the most

practical method.

35-tph CRUSHING AND SCREENING PLANT

Function and Operation. The 35-tph plant consists of two relatively small, self-contained units. It is intended

primarily to produce material needed to support light construction, maintenance, and repair projects of combat

battalions.

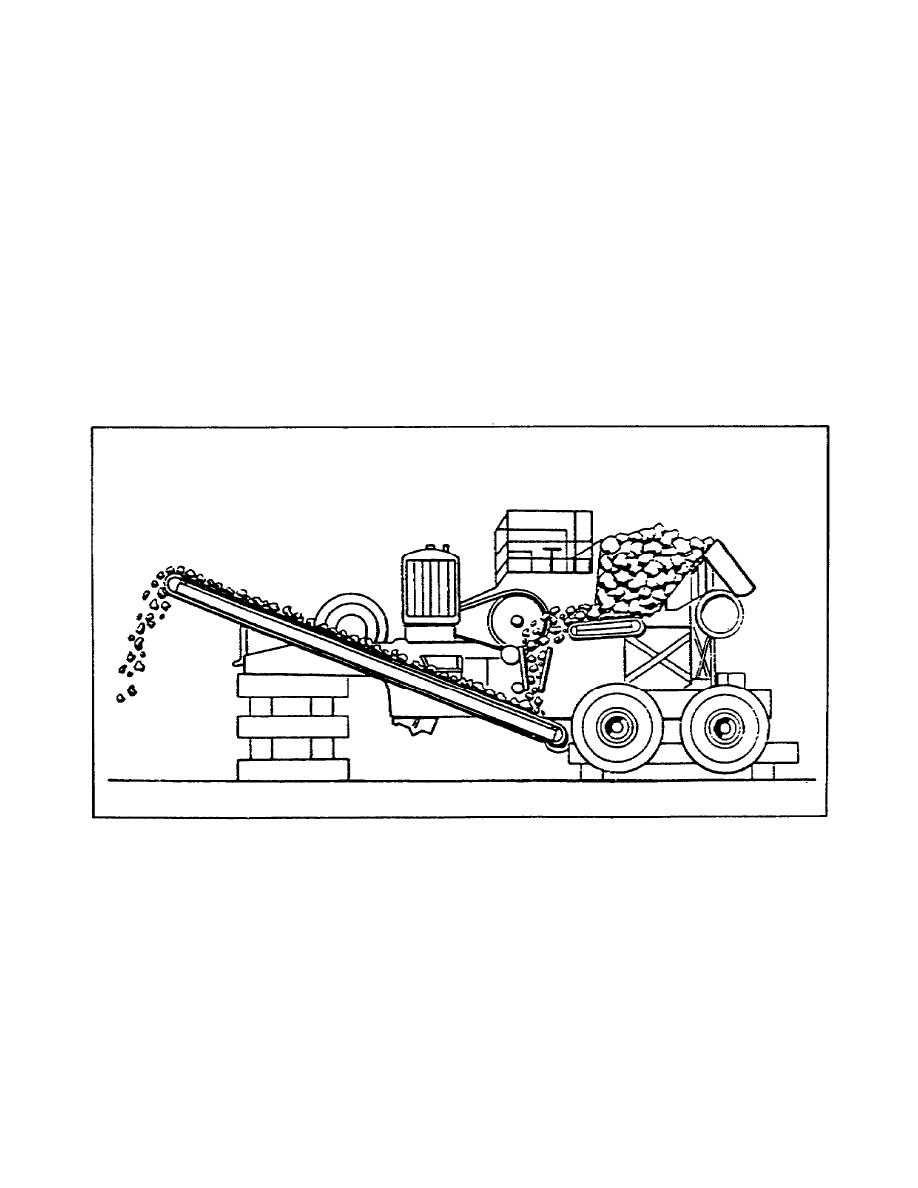

The primary unit is used for initial reduction of quarry run rock and gravel (Figure 9). It is ideally

suited to processing gravel pit source rock. Due to the relatively small jaw cavity opening (15 x24 inches) it is

very difficult to reduce material to the ideal feed size by blasting in the quarry. The product of the primary

crusher is suitable for base course material without further processing.

FIGURE 9. MATERIAL FLOW THROUGH THE PRIMARY UNIT

OF A 35-tph CRUSHING AND SCREENING PLANT

The secondary unit is used to accept the product of the primary crusher. It accomplishes necessary

further reduction in particle size and screens the material into size ranges to meet specifications (Figure 10).

18

Previous Page

Previous Page