Lesson 1/Leaning Event 3

The type of material being processed and the finished product size both have a substantial influence upon the

hourly production rate of the secondary unit. The actual rate of production may be limited to the capacity of the

top screen, the capacity of the bottom screen, or in some cases upon the crushing capacity of the dual roll crusher.

Graded aggregate is normally obtained by processing raw material through both units of the plant. Frequently it is

most feasible to use only the primary unit to make base course material. In this case the fines are usually needed

for binder and therefore screening is not required.

75-tph CRUSHING AND SCREEN PLANT

The 75-tph plant is a medium to large plant with substantial processing capability. It is primarily used to support

construction activities of Engineer Battalions. It is subdivided into two separate and distinct sets of equipment.

These sets are described below.

75-tph Plant, Set No. 1

Function and Operation. This set consists of primary and secondary units.

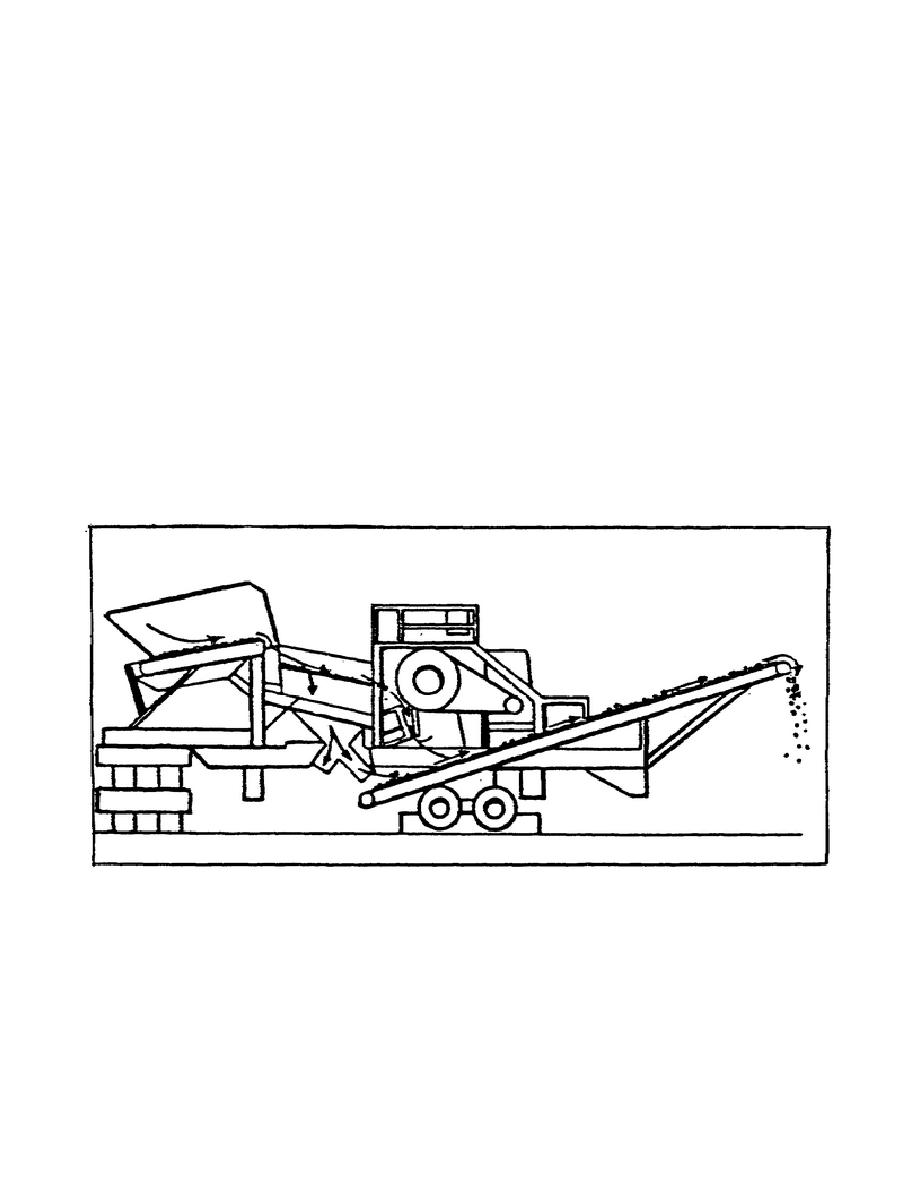

The primary unit (Figure 11) is used to accomplish the first stage of reduction of quarry run rock. It is also

frequently used to crush coarse gravel. When used by itself, the product is suitable for base course material only.

FIGURE 11. MATERIAL FLOW THROUGH THE PRIMARY UNIT OF

A 75-tph CRUSHING AND SCREENING PLANT, SET NO. 1

20

Previous Page

Previous Page