follows placing and consolidating the plastic concrete. Hydration continues indefinitely at a decreasing rate as

long as the mixture contains water and the temperature conditions are favorable. Once the water is removed,

hydration ceases and cannot be restarted.

CURING FACTORS

Importance

Curing is the period of time from consolidation to the point when the concrete reaches its design strength. During

this period, you must take certain steps to keep the concrete moist and as near to 73F as practicable. The

properties of concrete, such as freeze and thaw resistance, strength, watertightness, wear resistance, and volume

stability, cure or improve with age as long as you maintain the moisture and temperature conditions favorable to

continued hydration.

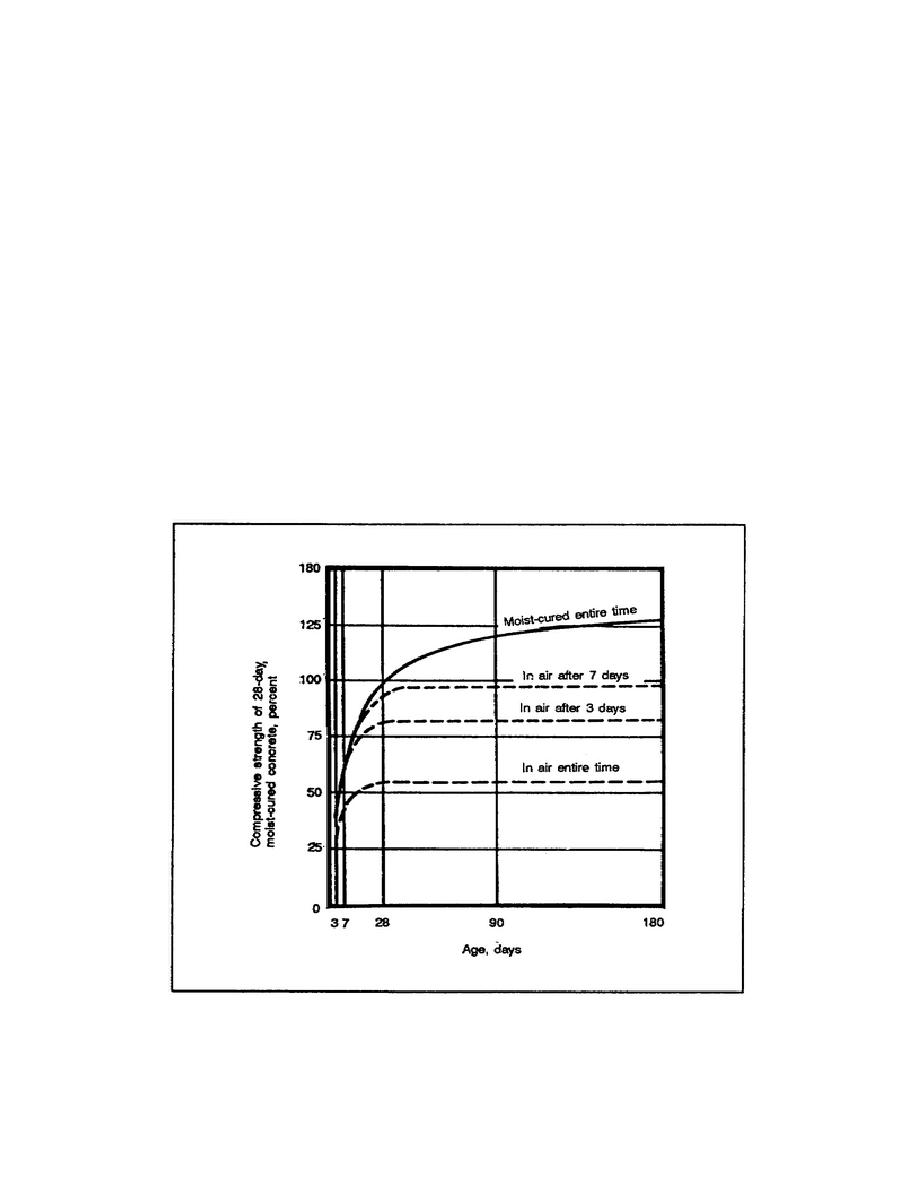

Length of Curing Period

The length of time that you must protect concrete against moisture loss depends on the type of cement used, mix

proportions, required strength, size and shape of the concrete mass, weather, and future exposure conditions. The

period can vary from a few days to a month or longer. For most structural use, the curing period for cast-in-lace

concrete is usually 3 days to 2 weeks, depending on conditions such as temperature, cement type, and mix

proportions. Bridge decks and other slabs exposed to weather and chemical attack usually require more extended

curing periods. Figure 4-12 shows how moist curing affects the compressive strength of concrete.

Figure 4-12. Moist curing effect on compressive strength of concrete.

4-21

EN5466

Previous Page

Previous Page