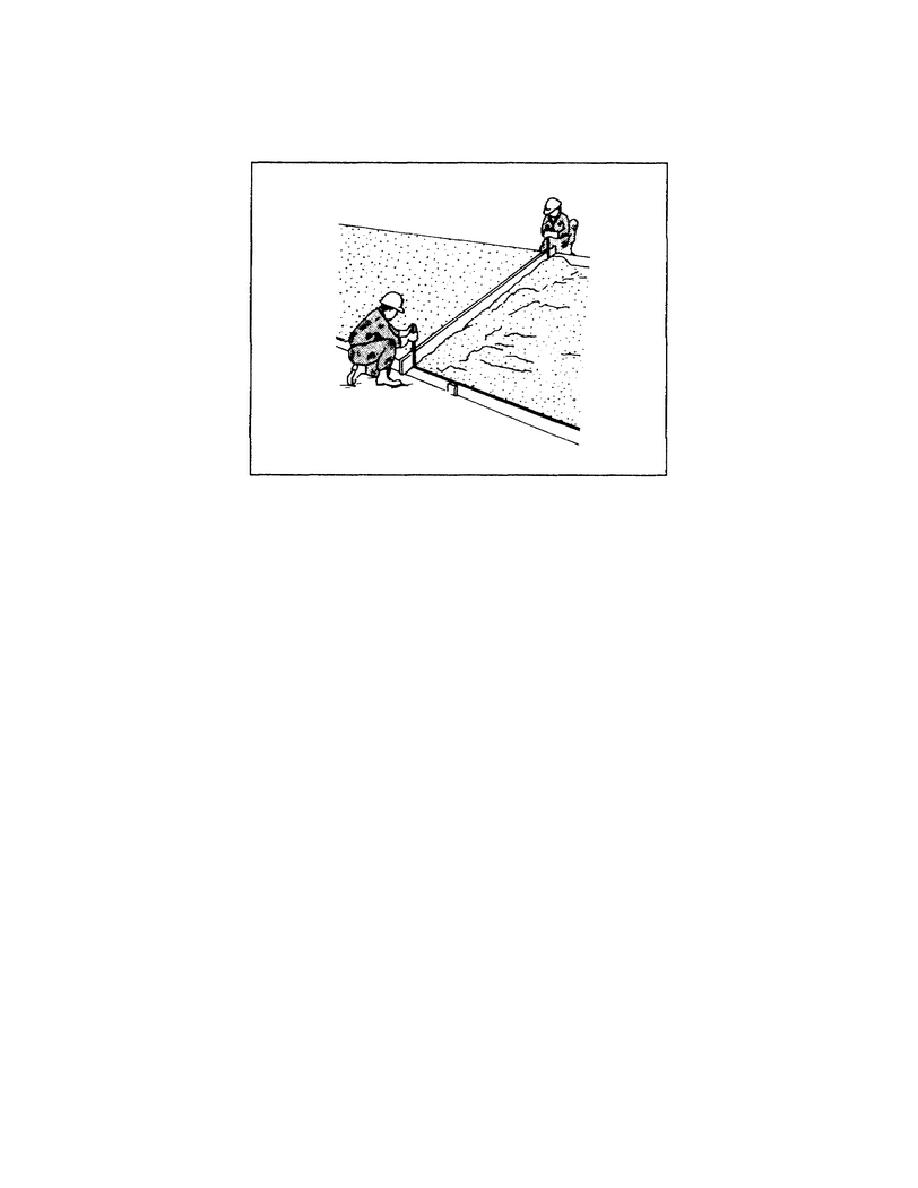

on surfaces more than 10 feet wide. Three workers (excluding a vibrator operator) can screed approximately 200

square feet of concrete per hour. Two of the workers can operate the screed while the third pulls excess concrete

from the front of the screed.

Figure 4-9. Screeding operation.

Floating

If you require a surface smoother than that obtained by screeding, work the surface sparingly using either a wood

or aluminum magnesium float or a finishing machine. The wood float in view 1 of Figure 4-10 is shown in use in

view 2 of Figure 4-10. Begin floating immediately after screeding, while the concrete is still plastic and

workable, and before any bleed water appears on the surface. Floating has three purposes: to embed aggregate

particles just beneath the surface, to remove slight imperfections and high and low spots, and to compact the

concrete at the surface in preparation for other finishing operations. Do not overwork the concrete while it is still

plastic or you will bring an excess of water and paste to the surface. This fine material will form a thin, weak

layer that will scale or wear off under use. To produce a coarse texture as the final finish, you usually have to

float the surface a second time after it partially hardens. Use a long-handled wood float for slab construction, as

shown in view 3 of Figure 4-10. You use an aluminum magnesium float the same way as the wood float, but it

gives the finished concrete a much smoother surface. To avoid cracking and dusting of the finished concrete,

begin aluminum floating when the water sheen disappears from the freshly placed concrete surface. Do not use

either cement or water as an aid in finishing the surface.

EN5466

4-18

Previous Page

Previous Page