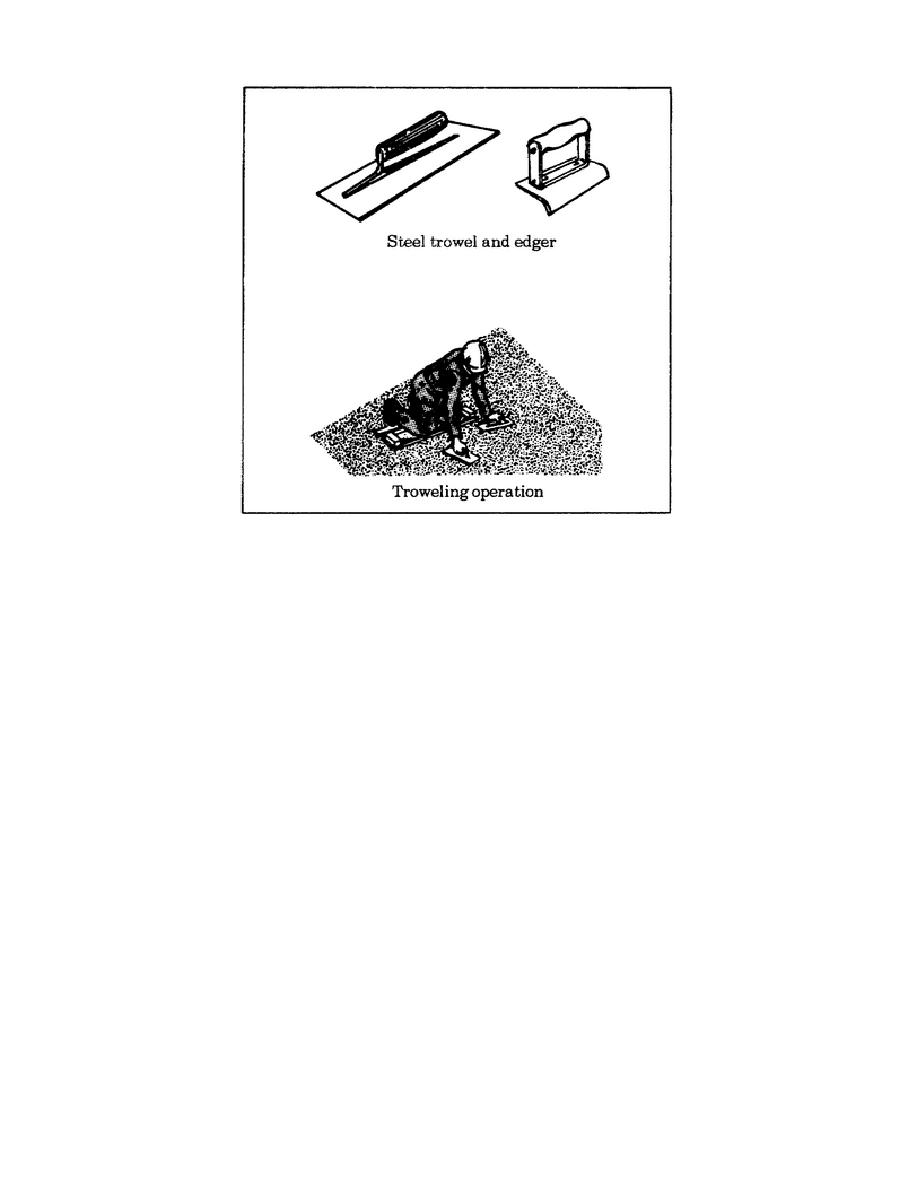

Figure 4-11. Steel finishing tools and troweling operation.

Brooming

You can produce a nonskid surface by following the floating operation (after waiting 10 to 15 minutes) by

brooming the concrete before it hardens thoroughly. When severe scoring is not desirable, such as in some floors

and sidewalks, you can produce the broomed finish using a hairbrush after troweling the surface once to a smooth

finish. However, when rough scoring is specified, use a still broom made from either steel or coarse fiber. The

direction of scoring when brooming should be at right angles to the direction of the traffic.

Rubbing

The most uniform and attractive surface requires a rubbed finish, although you can produce a surface having a

satisfactory appearance simply by using plywood or lined forms. As soon as the concrete hardens, rub the surface

first with coarse carborundum stones so that the aggregate does not pull out. Then, allow the concrete to cure

before the final rubbing with finer carborundum stones. Keep the concrete damp while rubbing. To properly cure

any mortar used as an aid in this process and left on the surface, keep it damp for 1 to 2 days after it sets. Restrict

the mortar layer to a minimum because it is likely to scale off and mar the surface appearance.

CURING

Hydration

Adding water to portland cement to form the water-cement paste that holds concrete together

starts a chemical reaction that makes the paste into a bonding agent.

This reaction, called

hydration, produces a stonelike substance--hardened cement paste.

Both the rate and degree of

hydration and the resulting strength of the final concrete, depend on the curing process that

EN5466

4-20

Previous Page

Previous Page