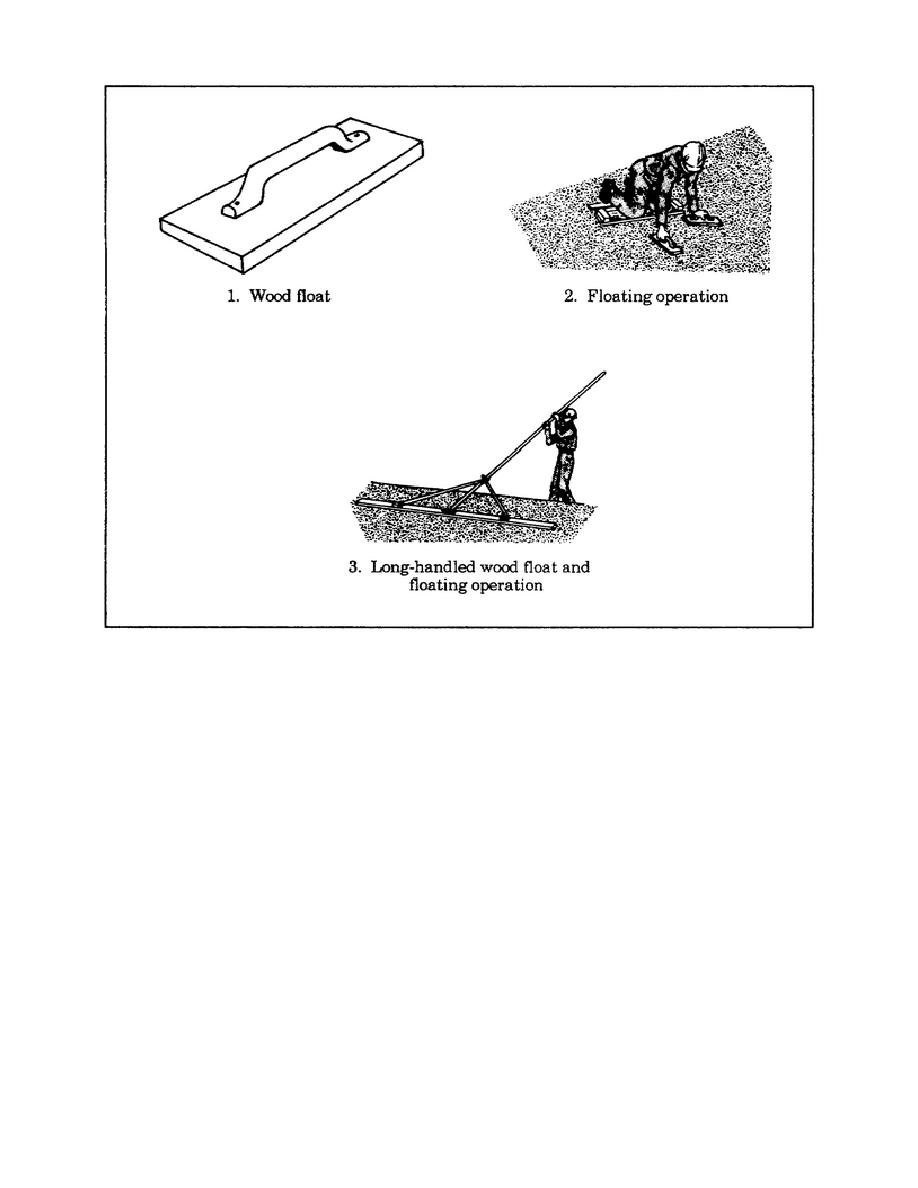

Figure 4-10. Wood floats and floating operations.

Troweling

For a dense smooth finish, follow floating with steel troweling (see Figure 4-11 on page 4-20) when the moisture

film or water sheen disappears from the floated surface and the concrete has hardened enough to prevent fine

material and water from working to the surface. But delay this operation as long as possible. Too much

troweling too soon tends to produce crazing and reduces durability. However, too long a delay in troweling

makes the surface hard to finish properly. Troweling should leave the surface smooth, even, and free from marks

and ripples. Avoid wet spots if possible. When they do occur, do not resume finishing operations until the water

has been absorbed, evaporated, or mopped up. When a wear-resistant and durable surface is required, it is poor

practice to spread dry cement on the wet surface to absorb excess water. You can obtain a surface that is fine-

textured, but not slippery, by a second light troweling over the surface with a circular motion immediately

following the first regular troweling, keeping the trowel fiat against the surface. When a "hard steel-troweled

finish" is specified, follow the first regular troweling with a second troweling only after the concrete is hard

enough that no paste adheres to the trowel and passing the trowel over the surface produces a ringing sound.

During this final troweling, tilt the trowel slightly and exert heavy pressure to compact the surface thoroughly.

Hair cracks usually result from a concentration of water and fines at the surface due to overworking the concrete

during finishing operations. Too rapid drying or cooling aggravates such cracking. You will usually close cracks

that develop before troweling by pounding the concrete with a hand float.

4-19

EN5466

Previous Page

Previous Page