4-inch piece of lumber, and are lapped at the form corners to add rigidity. Double wales not only

reinforce the studs but also tie prefabricated panels together and keep them aligned.

Braces. Although braces are neither part of the form design nor considered as providing any additional

strength, they help stabilize the form. Of the many types of braces, the most common is a combination of

a diagonal member and a horizontal member nailed to a stake at one end and to a stud or wale on the

other. The diagonal member makes a 20- to 60-degree angle with the horizontal member. To add more

bracing you can place vertical members (strongbacks) behind the wales, or vertical members in the angle

formed by intersecting wales.

Spreaders. Spreaders are small pieces of wood placed between the sheathing panels to maintain the

proper wall thickness between them. They are cut to the same length as the wall thickness. Because

friction, not fasteners; holds the spreaders in place, you can remove them easily before the concrete

hardens. Attach a wire, off centered, securely through the spreaders, as shown in Figure 3-1, to pull them

out when the fresh concrete exerts enough pressure against the sheathing to permit removal.

Tie wires. Tie wires secure the formwork against the lateral pressure of the plastic concrete. They always

have double strands.

Tie rods. Tie rods are easier to work with and sometimes replace tie wires in the same function.

Column Forms

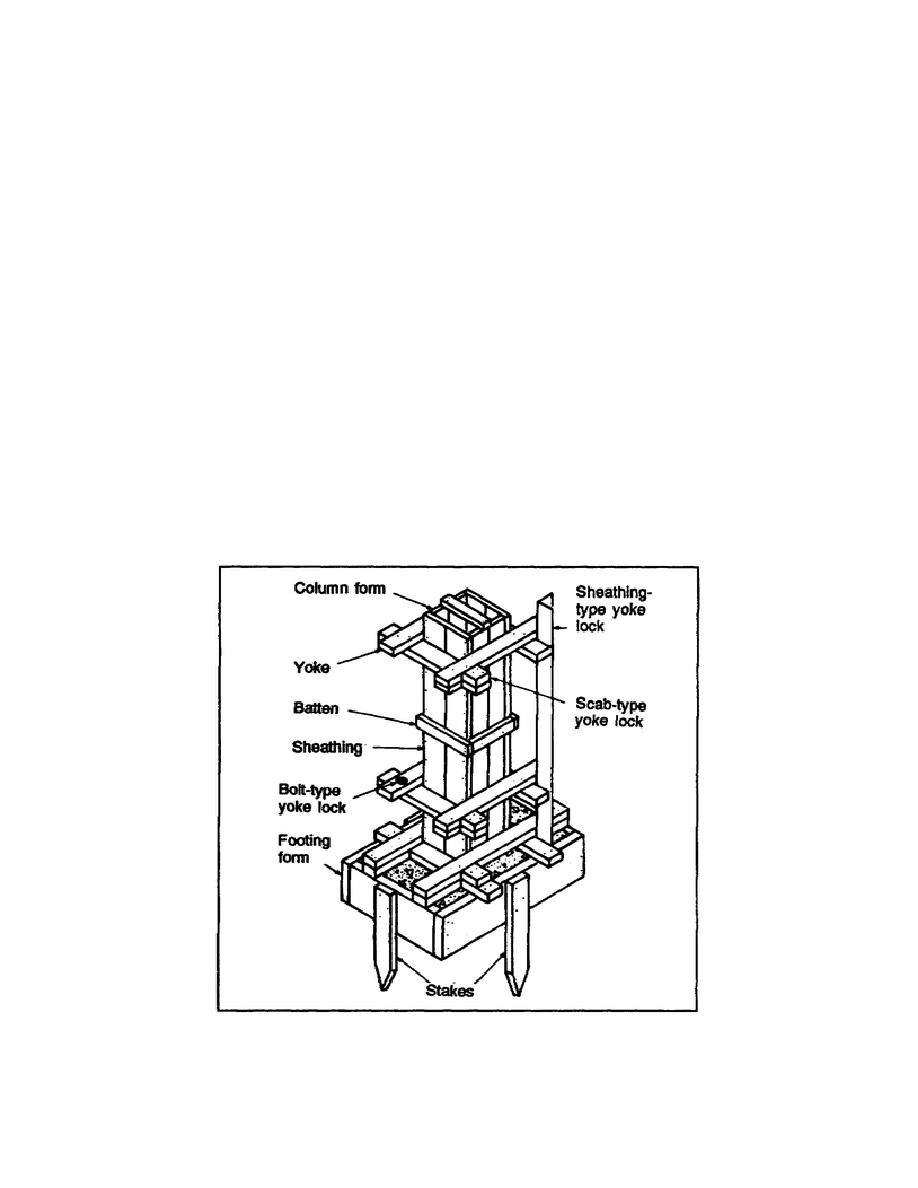

Figure 3-2 shows the basic parts of a wood for a concrete column.

Figure 3-2. Form for a concrete column and footing.

3-3

EN5466

Previous Page

Previous Page