Form Characteristics

Forms must be tight, rigid, and strong. Loose forms permit either loss of cement, resulting in honeycomb, or loss

of water, causing sand streaking. Brace forms enough to align them and make them strong enough to hold the

concrete. Take special care in bracing and tying down forms used for such configurations as retaining walls that

are wide at the bottom and that taper toward the top. The concrete in this and other types of construction, such as

the first pour for walls and columns, tends to lift the form above its proper elevation. To reuse forms, make them

easy to remove and replace without damage. The easiest way is to oil the forms before placing the concrete.

Form Materials

Forms are generally made from four different materials: wood, metal, earth, and fiber. Metal forms are more

expensive than wood, but are more economical if reused enough. The material you will use is wood.

FORMING

Wall Forms

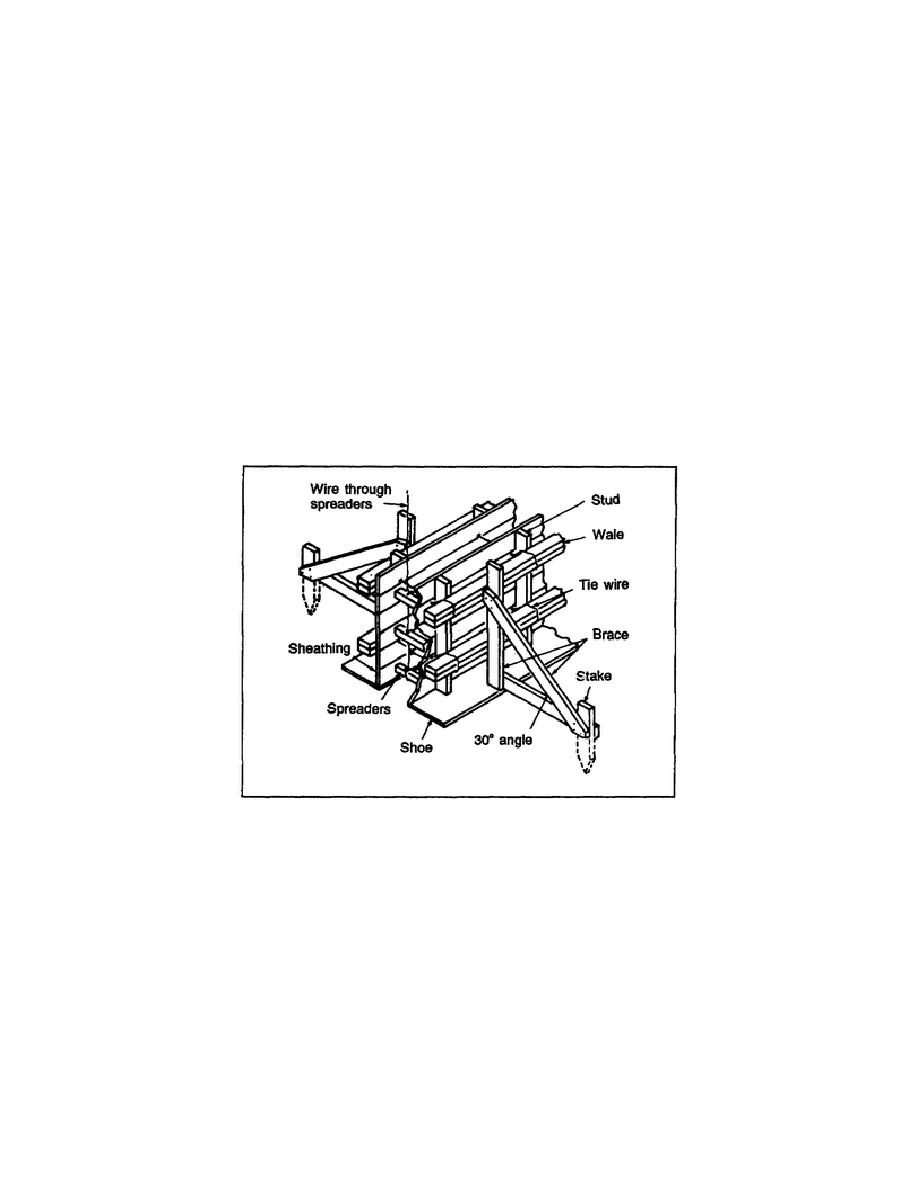

Figure 3-1 shows the basic parts of a wood form for panel walks.

Figure 3-1. Wood form for a concrete panel wall.

Sheathing. Sheathing forms the vertical surfaces of a concrete wall. The sheathing must be watertight.

Although sheathing made from tongue-and-groove lumber gives the smoothest and most watertight

concrete surface, you can also use plywood or fiber-based hardboard.

Studs. Vertical studs add rigidity to the wall forms. They are made from single 2- by 4-foot or 2- by 6-

foot lumber.

Wales (walers). Wales reinforce the studs when they extend upward more than 4- or 5-feet.

They should be made from doubled 2- by 4-inch, 2- by 6-inch, or a single 4- by

EN5466

3-2

Previous Page

Previous Page