Coarse aggregate should be graded up to the largest practicable size for the job conditions. According to the

American Concrete Institute (ACI) 318-83, nominal maximum size of coarse aggregate cannot be larger than one-

fifth the narrowest dimension between the sides of forms, nor one-third the depth of slabs, nor three-fourth the

minimum clear spacing between individual reinforcing bars or wires, bundles of bars, or prestressing tendons or

ducts. The type of equipment also limits the aggregate size. The 16S mixer can handle up to 3 inches of

aggregate, while the maximum size aggregate for the M919 concrete mobile is 1.5 inches. These limitations may

be waived if, in the judgment of the engineer, workability and methods of consolidation are such that concrete can

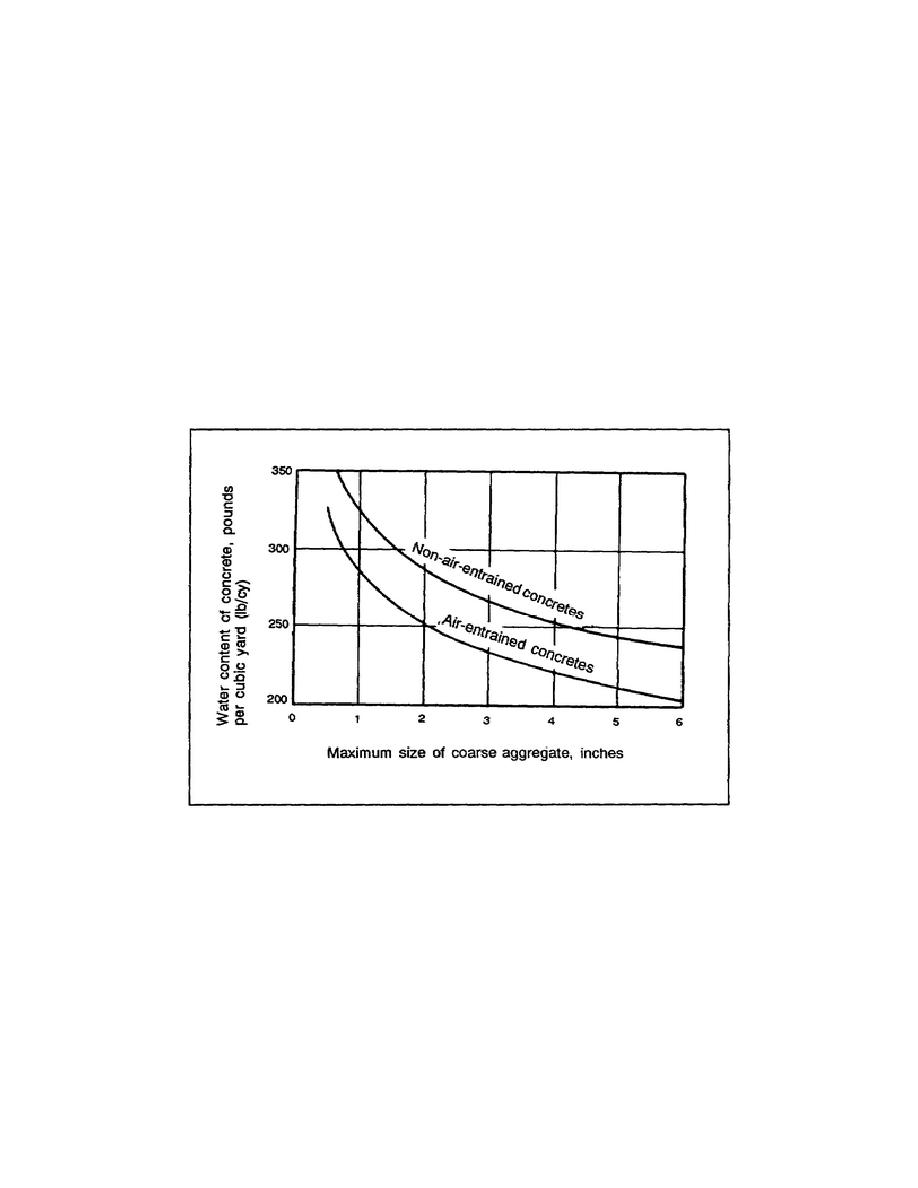

be placed without honeycomb or voids. The larger the maximum size of the coarse aggregate, the less paste

(water and cement) required to produce a given quality. Field experience shows that the amount of water required

per unit volume of concrete for a given consistency and given aggregates is nearly constant, regardless of the

cement content or relative proportions of water to cement. Further, the amount of water required decreases with

increases in the maximum size of the aggregate. The water required per cubic yard of concrete with a slump of 3

to 4 inches is shown in Figure 1-3 for a wide range of coarse-aggregate sizes. The figure demonstrates that for a

given w/c ratio, the amount of cement required decreases as the maximum size of coarse aggregate increases.

However, in some instances, especially in higher strength ranges, concrete containing smaller maximum-size

aggregate has a higher compressive strength than concrete with larger maximum-size aggregate at the same w/c

ratio.

Figure 1-3. Water requirement for concrete of a given consistency

as a function of coarse-aggregate size.

Bulk Unit Weight

The weight of the aggregate that fills a 1-cubic-foot container. This term is used because the volume contains

both aggregate and voids air spaces.

1-11

EN5466

Previous Page

Previous Page