rounded or cubed particles. Angular particles require more cement paste to coat them, making the concrete more

expensive. For most purposes, aggregates should be clean, hard, strong, durable, and free from chemicals or

coatings of clay or other fine materials that affect the bond of the cement paste. The most common contaminating

materials are dirt, silt, clay, mica, salts, and humus or other organic matter that appears as a coating or as loose,

fine material. You can remove many contaminants simply by washing the aggregate. However, test coarse

aggregate containing easily crumbled or laminated particles. The most commonly used aggregates are sand,

gravel, crushed stone, and blast-furnace slag. They produce normal weight concrete (concrete that weighs 135 to

160 pounds per cubic foot). Normal weight aggregates should meet "Specifications for Concrete Aggregates,"

which restricts contaminating substances and provide standards for gradation, abrasion resistance, and soundness.

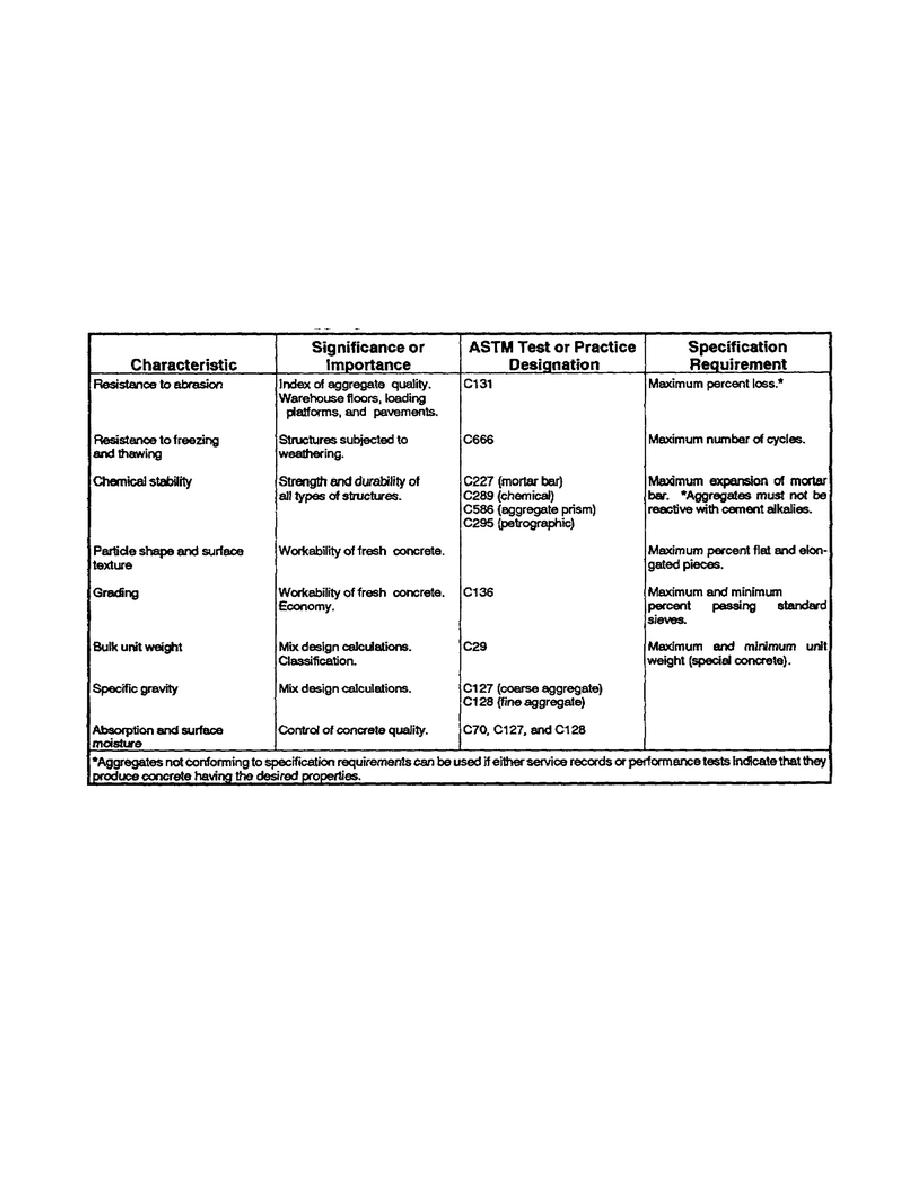

Aggregate characteristics, significance, and standard tests for evaluating these characteristics are given in Table

1-1 and discussed below.

Table 1-1. Aggregate characteristics and standards tests.

Aggregate Size, Distribution, and Grading

These affect the concrete's workability, economy, porosity, and shrinkage. For example, experience shows

that very fine sands are uneconomical, whereas very coarse sands produce harsh, unworkable mixes.

The proportioning of the different particle sizes is called grading an aggregate. Grading is controlled

by the aggregate producer. The particle size distribution of aggregate is determined by separation with a series

of standard sieves. The six standard sieves for fine-aggregate are Nos 4, 8, 16, 30, 50, and 100. Sieves for

coarse aggregate are 3, 1 1/2, 3/4, and 3/8 inch, and No 4. The number of a fine-aggregate sieve corresponds

to the number of meshes (square openings) to the linear inch that the sieve contains. The higher the

number, the finer the sieve. Any material retained in the No 4 sieve is considered coarse aggregate,

and any material that passes the No 200 sieve is too fine for concrete. The finest coarse-aggregate

1-7

EN5466

Previous Page

Previous Page