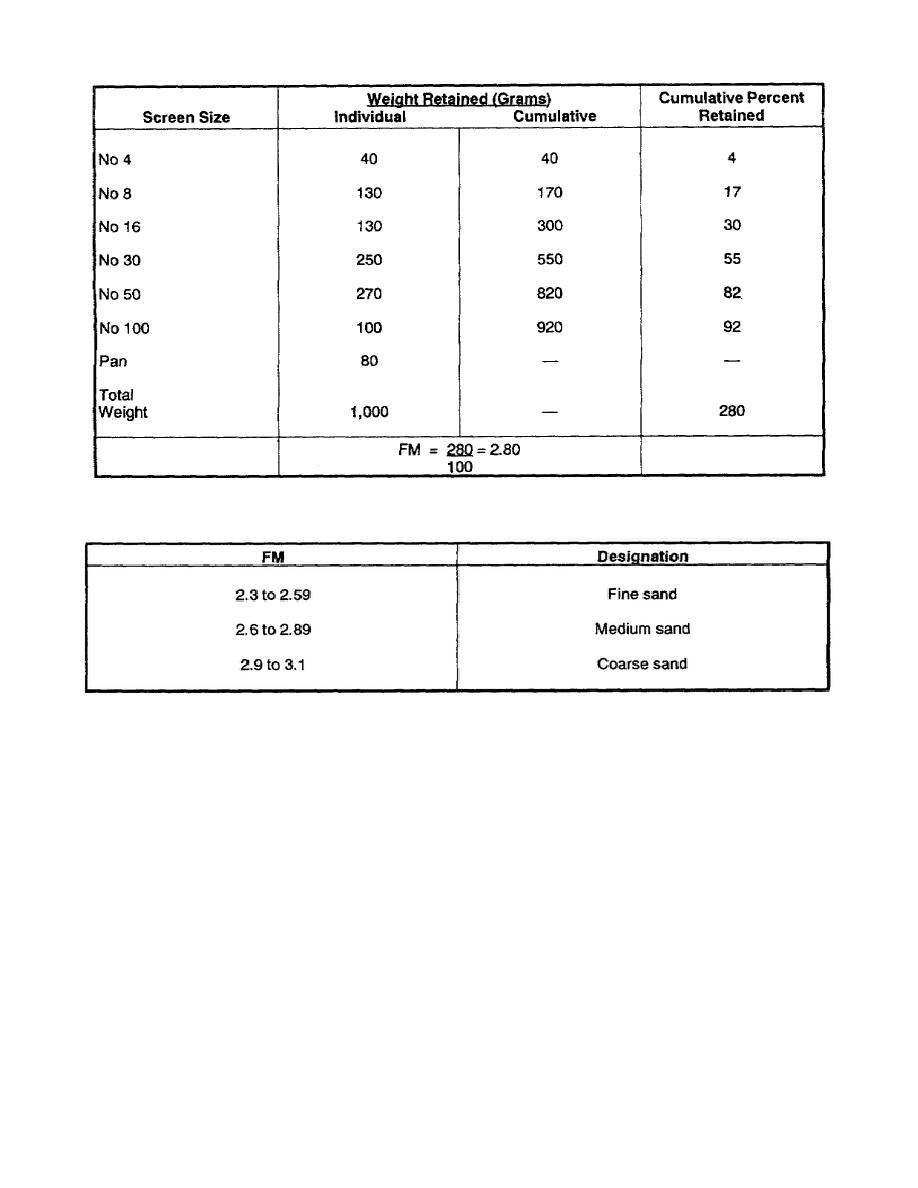

Figure 1-2. Typical FM calculation.

Table 1-2. FM ranges for fine aggregate.

Fine-aggregate grading. The selection of the best fine-aggregate grading depends on the application,

richness of the mix, and the maximum size of coarse aggregate used. In leaner mixes, or when small

coarse aggregate is used, a fine-aggregate grading near the maximum recommended percentage passing

each sieve is desirable for workability. In richer mixes, coarser fine-aggregate gradings are desirable for

economy. In general, if the water and cement ratio is kept constant and the ratio of fine-to-coarse

aggregate is chosen correctly, you can use a wide range of fine-aggregate gradings without much effect

on strength. Grading is expressed as the percentages by weight passing through the various standard

sieves. The amount of fine aggregate passing the No 50 and 100 sieves affects workability, finished

surface texture, and water gain or bleeding. For thin walls, hard-finished concrete floors, and smooth

concrete surfaces cast against forms, the fine aggregate should contain not less than 15 percent passing

the No 50 sieve and at least 3 or 4 percent, but not more than 10 percent, passing the No 100 sieve. These

minimum amounts of fines give the concrete better workability, make it more cohesive, and produce less

water gain or bleeding than lower percentages of fines. In no case should the percent passing a No 200

sieve exceed 5 percent and only 3 percent if the structure is exposed to abrasive wear. Aggregate

gradings falling within the limits are generally satisfactory for most concretes.

1-9

EN5466

Previous Page

Previous Page