Lesson 6/Learning Event 4

(7) As previously determined, bins #3 and #4 must feed 32.6 TPH each. Reading down the

proper column on Table 13, it is seen that the capacity closest to this is 32.9 TPH requiring 7 1/2

inch gate opening. Since the initial gate settings are only approximations, gates #3 and #4 are

each set at 7 1/2" openings and will be adjusted as necessary when operations begin.

(8) Bins #1 and #2 feed the fine aggregates onto tie rubber belt conveyor of the cold feed

unit. The proper table to use to determine the gate openings for these bins is Table 21.

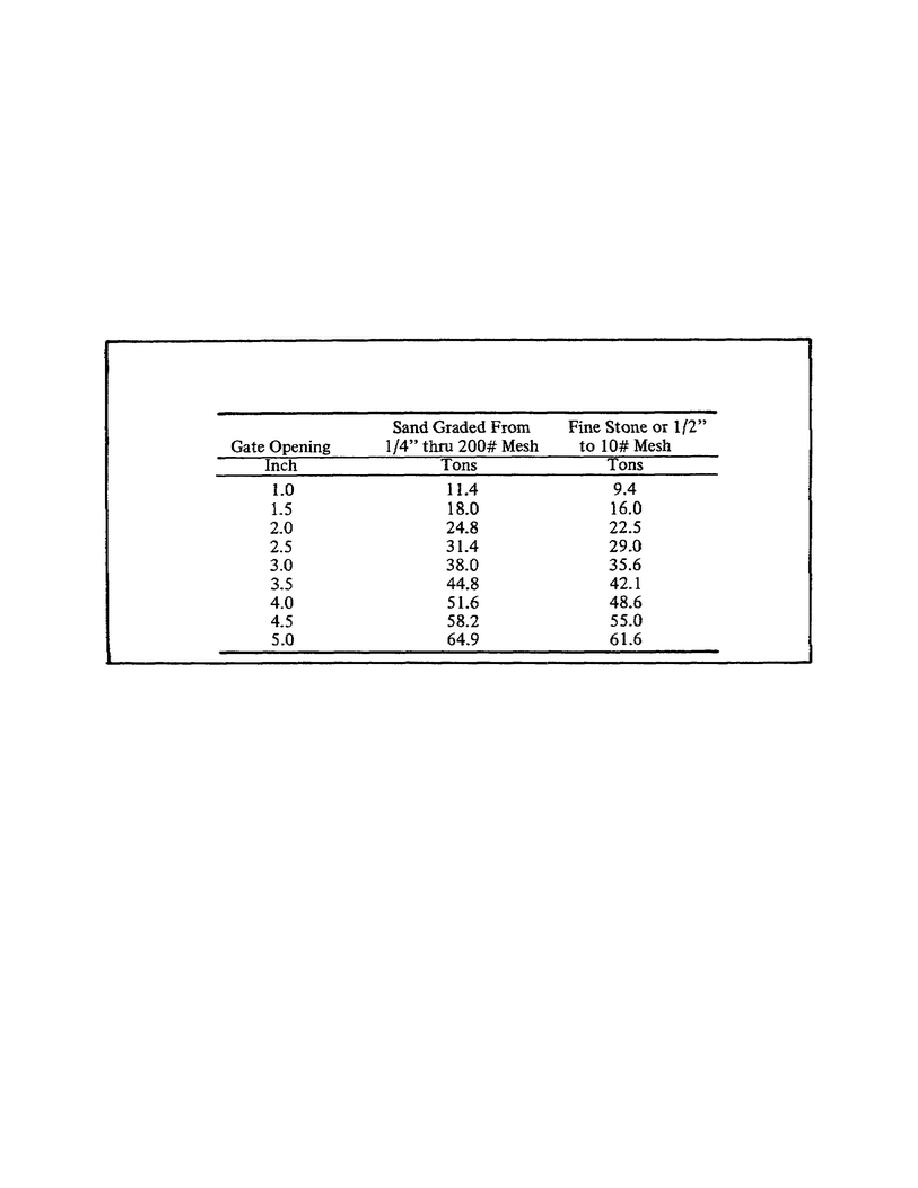

TABLE 21. FEEDING RATE (TONS PER HOUR) -

MODEL 815 FEEDER 12-INCH GATE WITH

BELT CONVEYOR

(9) The fine aggregate in bin #1 consists of 3/4" minus material. However, as seen in the

sieve analysis, only 2 percent of this material is larger than 1/2". The proper column in Table 21

to use to determine the gate opening would be the "Fine Stone" column. The required feeding

rate from bin #1 is 43.6 TPH. Reading down the "Fine Stone" column, it is seen that 43.6 TPH is

closest to the listed capacity of 42.1 TPH. Therefore, the #1 gate is set at a 3" opening and will

be adjusted as necessary when operations begin.

(10) Bin #3 is to feed sand at a required rate of 29.1 TPH. The proper column to use to

determine the gate opening is the "Sand" column. Reading down the "Sand" column, it is seen

that the required rate of 29.1 TPH falls approximately half way between the listed capacities of

24.8 TPH. Therefore, gate #1 is set at an opening approximately half way between the openings

listed for these capacities (2 1/4") and will be adjusted as necessary when operations begin.

As determined above, the cold feed gates are set as follows:

Gate #1

2 1/4"

Gate #2

3"

Gate #3

7 1/2"

Gate #4

7 1/2"

99

Previous Page

Previous Page