Lesson 6/Learning Event 4

feed gate openings. The gates are set to estimated openings which will feed the approximate

amount of aggregate required. Due to varying aggregate weights and sizes, accurate gate settings

can be made only after the operation begins. Final gate adjustments must be made to prevent the

gradation unit bins from overflowing or running low. Several adjustments may be necessary to

maintain a balanced aggregate flow to the gradation unit.

(2) One method of estimating the initial cold feed settings is shown in the following example.

In this example, the total aggregate in tons per hour must be determined. This is done by

dividing the dryer capacity (138 TPH) by the percent of dried aggregate in the total aggregate

(0.95). In this example, 145.3 tons of aggregate will be required per hour.

(3) The total aggregate is then multiplied by the percent required from each aggregate

stockpile (coarse agg, 0.45, fine agg, 0.30, sand, 0.20) to determine the feeding requirements

from each stockpile. Here it is seen that the mix will require 65.4 tons of coarse aggregate, 43.6

tons of fine aggregate, and 29.1 tons of sand each hour. The cold feed gates must now be

adjusted to feed approximately these amounts.

(4) Since the coarse aggregate must be fed at a rate of 65.4 TPH, it is recommended to divide

this aggregate equally between cold bins #3 and #4. By doing this, bins #3 and #4 will be

feeding coarse aggregate at a rate of 32.7 TPH each.

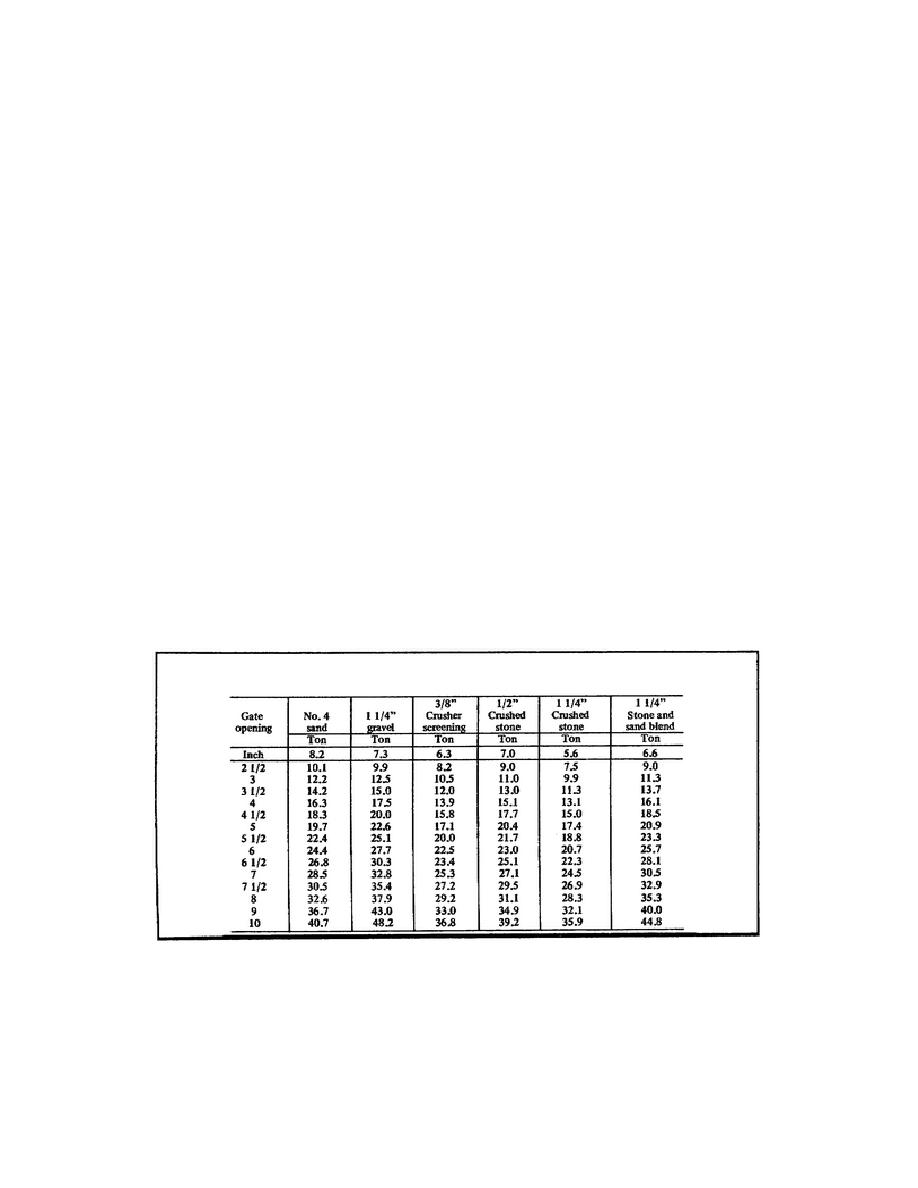

(5) To determine the gate openings required to feed this amount of coarse aggregate, refer to

Table 20. This table shows the approximate feeding rate of the reciprocating feeder for various

types of material.

TABLE 20. FEEDING RATE (TON PER HOUR) - MODEL 815 FEEDER

12-INCH GATE WITH RECIPROCATING FEEDER

(6) The sieve analysis of the coarse aggregate (Table 12, gradation of material) shows that

this material contains 1" maximum size aggregate with considerable fine material. Therefore,

the coarse aggregate may be classed as sand/aggregate mixture. The proper column to use in this

case would be the 1 1/4" Stone and Sand Blend (Table 20).

98

Previous Page

Previous Page