Lesson 6/Learning Event 4

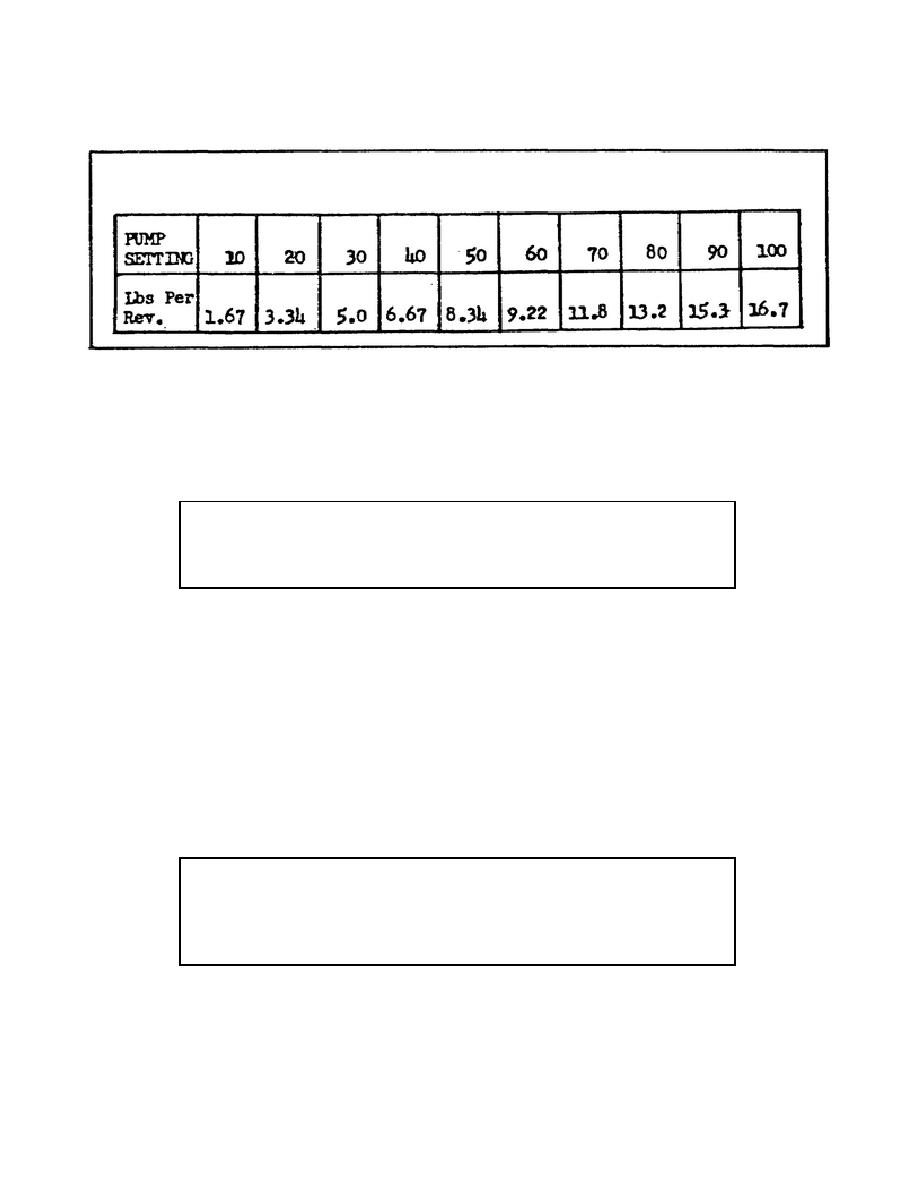

TABLE 19. METERING PUMP CAPACITY CHART

Example: Assume that the calculated lbs per gallon in the above example is 7.85.

The required pump discharge rate is 9.3 lbs per rev (from Step 6). This feeding rate falls

between 9.22 lbs per rev and 11.8 lbs per rev on the chart. By interpolating, it is found that the

required pump setting is 60.3.

NOTE: Since the pump dial is calibrated from 0 to 100 in increments of 1,

the .3 must be estimated between 60 and 61. When the pump has been set

and locked, a check should be made to insure that the proper pump output

is being obtained.

If the calculated lbs per gallon is other than 7.85, the required feeding rate must be adjusted

before the pump setting is determined.

Refer to Step 9-1. In this example, the calculated lbs per gallon is 7.77. In this case, the 9.3 lbs

per rev delivery rate must be adjusted before it is used with the METERING PUMP CAPACITY

CHART to determine the pump setting. To do this, the average weight of asphalt at mixing

temperature (7.85 lbs per gal) is divided by the calculated weight of one gallon of the asphalt

being used (7.77 lbs.). The result is then multiplied by the required delivery rate (9.3 lbs per

rev). The corrected delivery rate based on 7.85 lbs per gallon is found to be 9.395 lbs per rev

rounded to 9.4 lbs per rev. Referring to the METERING PUMP CAPACITY CHART (Table

19), it is found that to deliver 9.4 lbs per rev, a setting of 60.7 is required.

NOTE: The adjusted lbs per rev serves as a correction factor for the

METERING PUMP CAPACITY CHART. It must be remembered that,

due to the difference in the weight of the asphalt being used and the basis

of the chart, though 9.4 lbs per rev is used to set the pump, the actual

pump output will be 9.3 lbs per rev.

(2) Pump output method (specific gravity NOT known). This method of calibrating the

metering pump consists of a series of weight samples and

96

Previous Page

Previous Page