Lesson 6/Learning Event 4

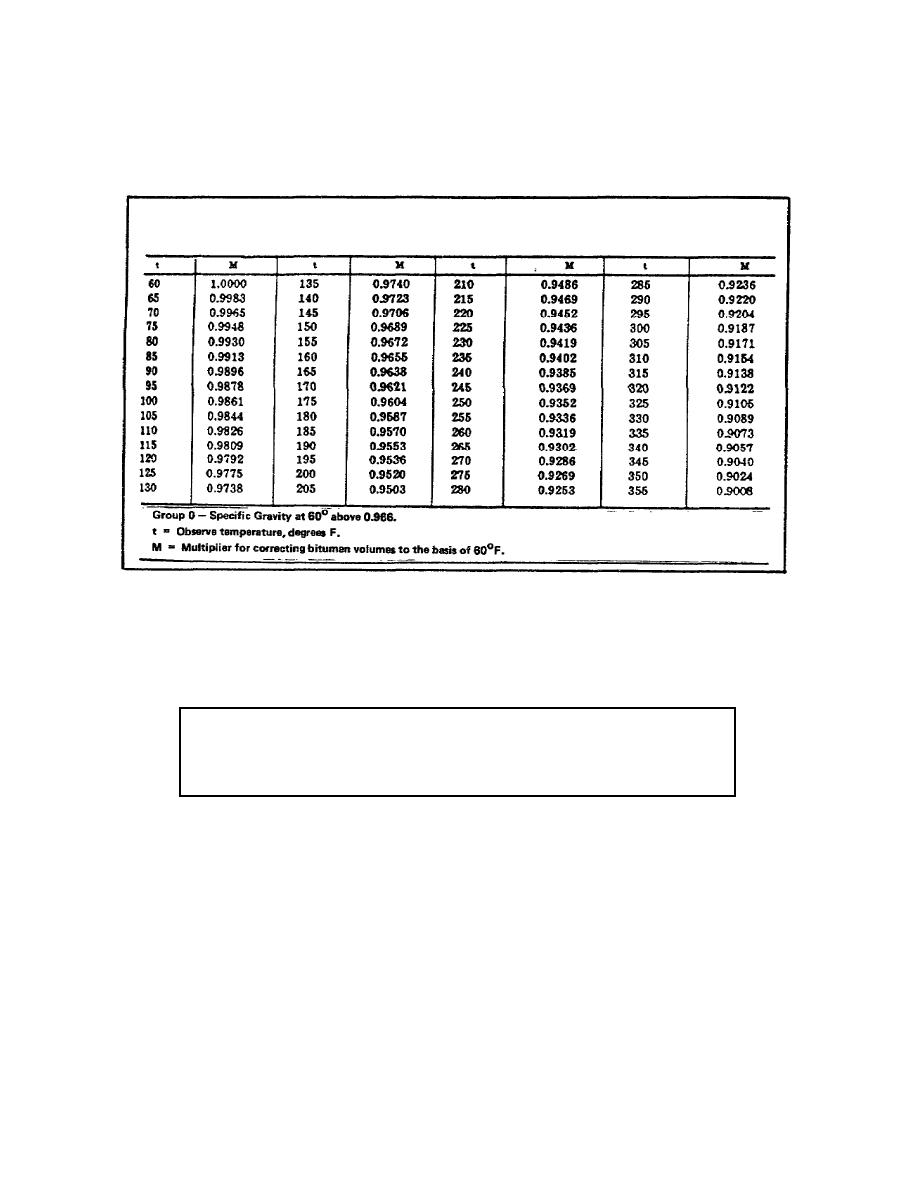

TABLE 18. TEMPERATURE-VOLUME CONVERSION

DATA FOR BITUMINOUS MATERIALS

Refer to Step 10. Once the temperature factor is obtained from Table 18, it is multiplied by the

specific gravity of the asphalt cement. The result of this multiplication is a conversion factor.

The conversion factor (in this example, 0.9325) is then multiplied by the average weight of one

gallon of asphalt cement at 60F.

NOTE: The manufacturer has established 8.328 lbs per US gal. and

10.002 lbs per Imperial gal. as the average weight of asphalt cement at

60F. For the purposes of this calculation, these figures are considered

constant.

By multiplying the conversion factor 0.9325 by 8.328 lbs per US gallon, it is determined that the

asphalt being used will weigh 7.77 lbs per gal at mixing temperature.

c. Determine the pump setting (Table 19).

The METERING PUMP CAPACITY CHART (Table 19) lists the discharge rate of the metering

pump in lbs per rev for the given pump setting. The chart is based on asphalt weighing 7.85 lbs

per gallon at mixing temperature.

If in the above example, the calculated lbs per gallon had been 7.85, then the pump setting

required to deliver 9.3 lbs per rev may be obtained directly from the chart.

95

Previous Page

Previous Page