Lesson 6/Learning Event 4

material, it is found that 18% will flow into Bin #2. (With available screens, it is possible to

separate 5/16-inch material (refer to Figure 20). The 5/16-inch material is selected for the

second separation leaving an aggregate balance of 35%.

Bin #3 has a capacity of 14%. Count up 14% from the 5/16-inch separation and read to

the left to where the percentage line intersects the gradation curve. The point of intersection lies

between the 1/3-inch and 5/8-inch vertical lines. Since no screen is available to separate the 5/8-

inch material the 1/2-inch material is selected as the separation allowing 10% of the aggregate to

flow into Bin #3. The remaining 25% of the aggregate will flow into Bin #4.

Screen Selection.

The vertical lines on which the bin separation were made on the gradation chart (Figure

20) represent the maximum size aggregate going into each bin. Screens must now be selected

which will allow these maximum sizes to pass.

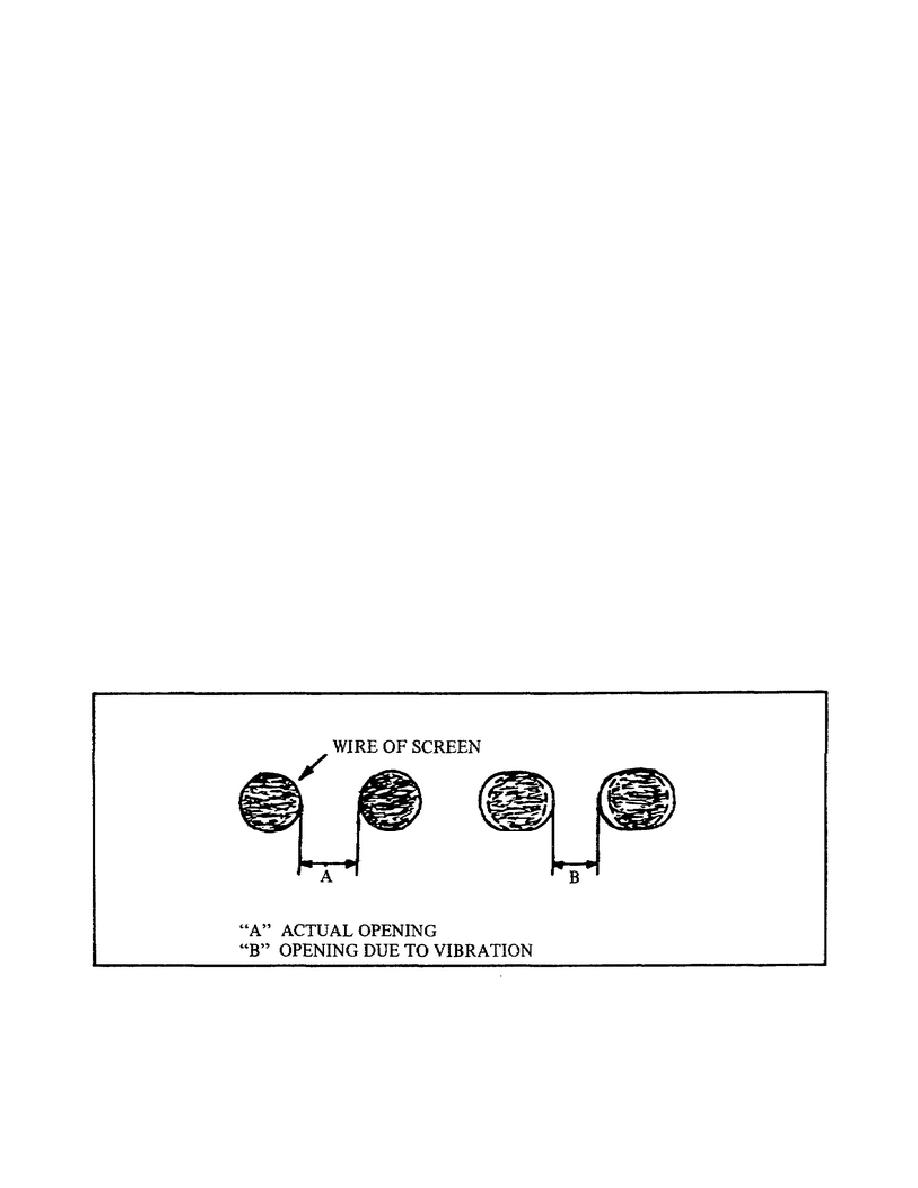

When choosing screens, an important factor must be remembered. During operation, the

vibration of the Screening deck reduces the clear space opening of the screens (Figure 21). The

screen openings must be larger than the material size desired to pass through the screen. In

Table 13, column B lists the screens available with the GQ60 gradation unit and column A lists

the material size that will pass each screen.

Therefore:

Bin #1 receives #6 material and smaller which requires a 5/32-inch screen to pass.

Bin #2 receives 5/16-inch to #6 material which requires a 3/8-inch screen to pass.

Bin #3 receives 1/2-inch to 5/16-inch material which requires a 9/16-inch screen

to pass.

Bin #4 receives 1-inch material which requires a 1-1/8-inch screen to pass.

FIGURE 21. SCREEN OPENING

83

Previous Page

Previous Page