Lesson 6/Learning Event 4

Example: Bitumen 6.0% (total mix)

Mineral filler 5.0% (aggregate in total mix)

100 - 6 = 94% (aggregate in total mix)

100 - 5 = 95% (dried aggregate in total aggregate)

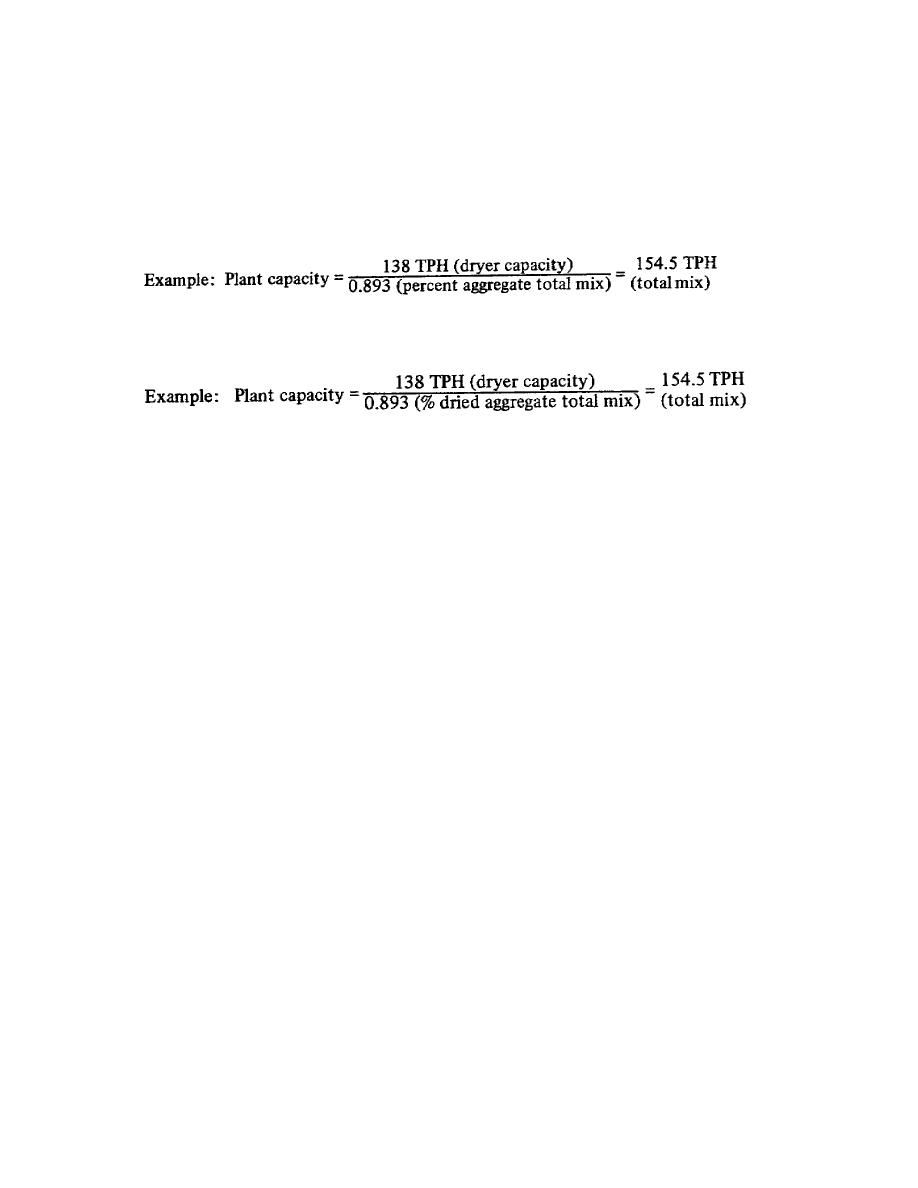

0.94 x 0.95 = 0.893 (or) 89.3% dried aggregate (total mix).

Or if Mineral Filer is Added:

NOTE: It should be remembered that the preceding example is calculated for maximum

capacity at 100% efficiency. During a sustained operation, due operating efficiency, the

actual plant output will be somewhat lower than this example.

In some instances it will be found that the screening capacity will be somewhat lower

than the dryer capacity. This condition normally occurs with a low aggregate moisture content

or when an extremely high percentage of fine aggregate is required for the mix. When this

condition occurs, substitute the screening capacity for the dryer capacity in the preceding

example.

Step 6. Determine the Feeding Rate.

The percent required from each gradation unit bin and the percent of mineral filler to be

fed by the fines feeder are expressed as a percent of the total aggregate. To determine the

percent of the total required from each component, multiply the percent of total aggregate from

each component by the percent of aggregate in the total mix.

Refer to above. The percentages listed in the second column of this example are the

percentages that were determined by screen selection. (Refer to Figure 20). However, these

percentages are of the total aggregate in the mix. The aggregate makes up only 94% of the total

mix. Therefore, by multiplying these percentages by 0.94, the percent of the total mix required

from each feeding component is determined. As a check for accuracy, add the percent of total

mix required from the four gradation unit bins and the percent of total mix required from the

fines feeder. The sum of these figures must equal the percent of aggregate in total mix (in this

case, 94%).

The percent of total mix required from each component is then multiplied by the plant

output. In Step 4, the plant output was calculated. In this example, 154.5 TPH will be the plant

output. Refer to above. The figures listed in the right column are the required amounts of

material from the appropriate component. Notice that these figures are in either lbs/rev or in

TPH. Again, as a check for accuracy, add these figures. The sum must equal the plant output.

87

Previous Page

Previous Page