Lesson 6/Learning Event 4

Step 7: Determine the Gradation Unit Feeder Speeds.

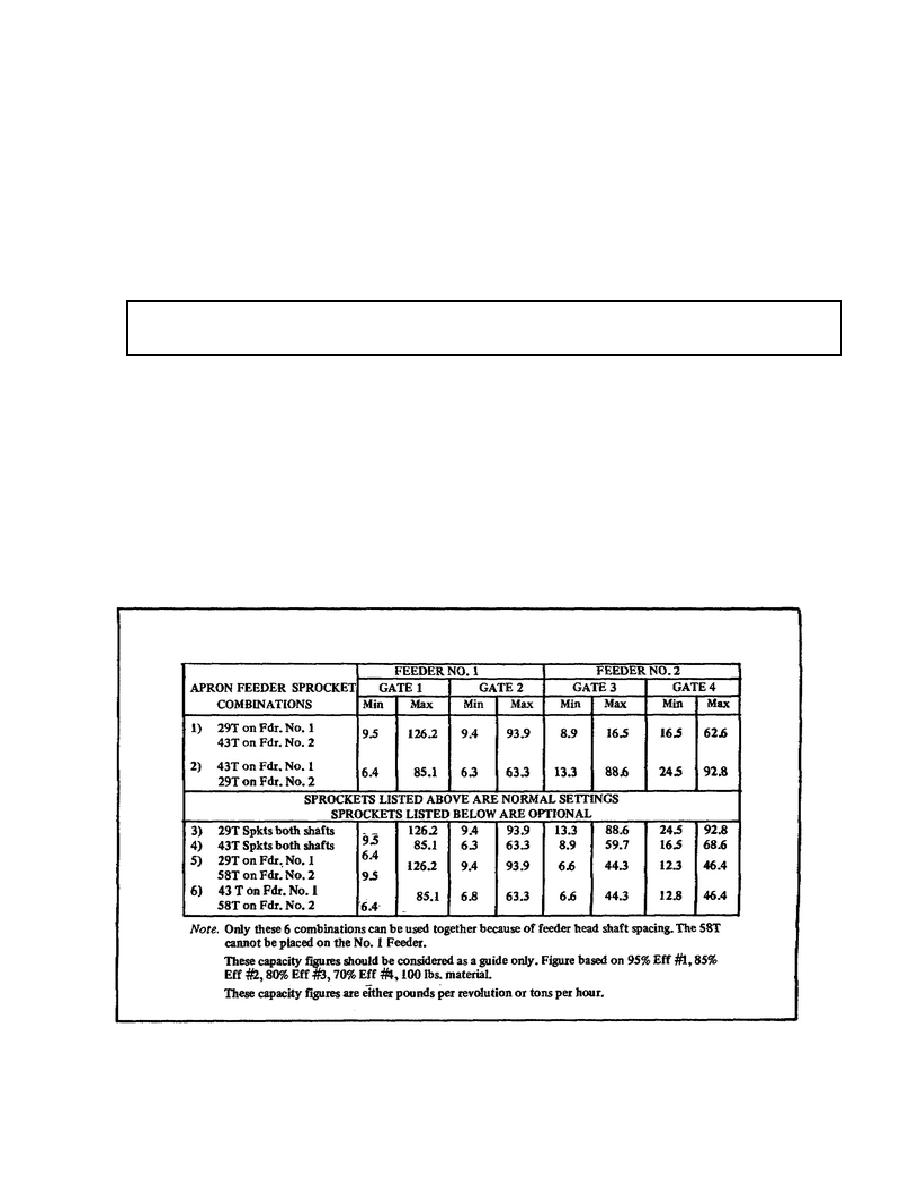

When the amount of material required from each bin has been determined, the apron

feeder sprocket combination can be selected and installed. Table 15 shows the approximate

feeding rates of the apron feeders for the six sprocket combinations available. Any sprocket

combination can be used if the required feeding rate falls within the sprocket combination

capacity range. However, best results will be obtained when the sprocket combination which

allows the required feeding rate to fall near the center of the capacity range is selected.

NOTE: A 29-tooth sprocket and a 43-tooth sprocket will be installed at the time of shipment.

These should cover the normal capacity ranges desired.

The feeding rates (from Determine the Feeding Rate paragraph), fall well within the

capacity range of sprocket combination # l (Table 15). Therefore, combination #1 is selected for

this example.

Example: Bin #1

61.0 29T sprocket on Feeder #1

Bin #2

26.1

Bin #3

14.5 43T sprocket on Feeder #2

Bin #4

36.3

TABLE 15. G6080 GRADATION UNIT APRON FEEDER

CAPACITY CHART

88

Previous Page

Previous Page