b. Care and Use of Cutting Tools. Cutting tools, like boring

tools, have sharp edges and points, which need to be sharpened and

protected. The term sharpen is used here in a broad sense to include

all of the operations required to put a saw in firstclass condition.

The master carpenter is an expert in using the right tool in the

right way.

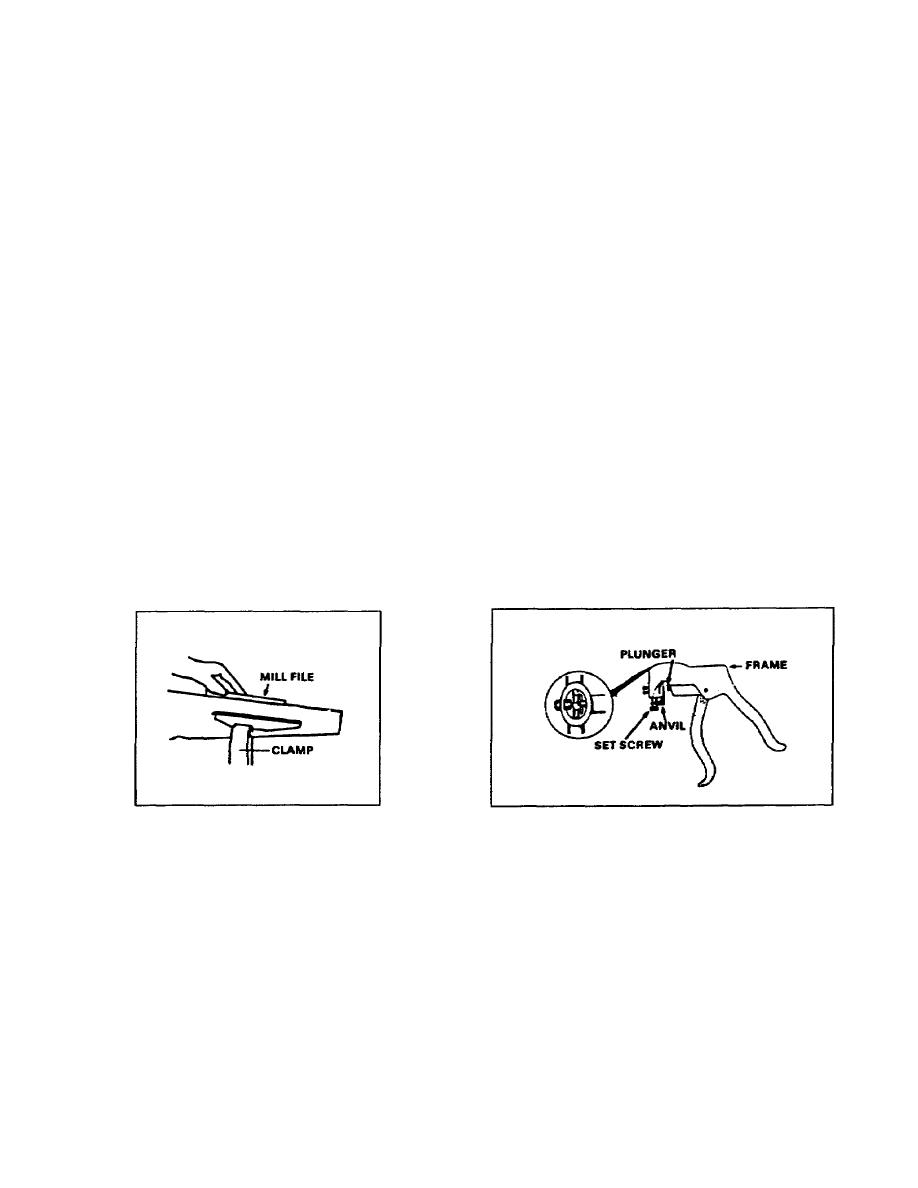

(1) Jointing. When a saw comes from the factory, the teeth are

all uniform in size, length, bevel, pitch, and set. After being used

and sharpened a few times, the teeth become distorted. When this

occurs, they must be filed to a straight line. This operation is

called jointing (Figure 212). When you joint a saw, place it in a

saw vise with the handle to the left. Starting with the heel end of

the saw, lay a flat file on top of the teeth and move it lightly

along the top of the teeth. Do not top the file. Continue this

operation until all teeth are even, with a slight crown at the top of

each tooth. If you find that the teeth are too short, which would

make them hard to set, file them to the proper shape before they are

set.

(2) Setting. After the teeth are made even by jointing, they

must be set. This means that every tooth will be bent a little to

give the blade sufficient clearance. For a handsaw, the set should

be half the thickness of the blade. This rule applies to both

crosscut saws and ripsaws. When using a saw set (Figure 213), bend

every other tooth (halfway from the point), starting at either end of

the saw. Do not attempt to hurry this operation; it takes skill and

practice to do it properly.

Figure 2-13.

Saw set

Figure 2-12.

Jointing a saw

(3) Filing. To file a crosscut saw (Figure 214, page 28),

place the saw securely in a saw vise with the handle to the left.

Using a threecornered file, start filing from the heel end. Place

the file between two teeth and incline it toward the small or tapered

end of the saw. File both teeth at once, using one or more strokes

and putting the same pressure on each stroke. Work down the length

of the saw, then turn the saw around so that the handle is to the

right. Incline the file to the tapered end, which is now to the

left, and again work down the length of the saw.

2-7

EN5155

Previous Page

Previous Page