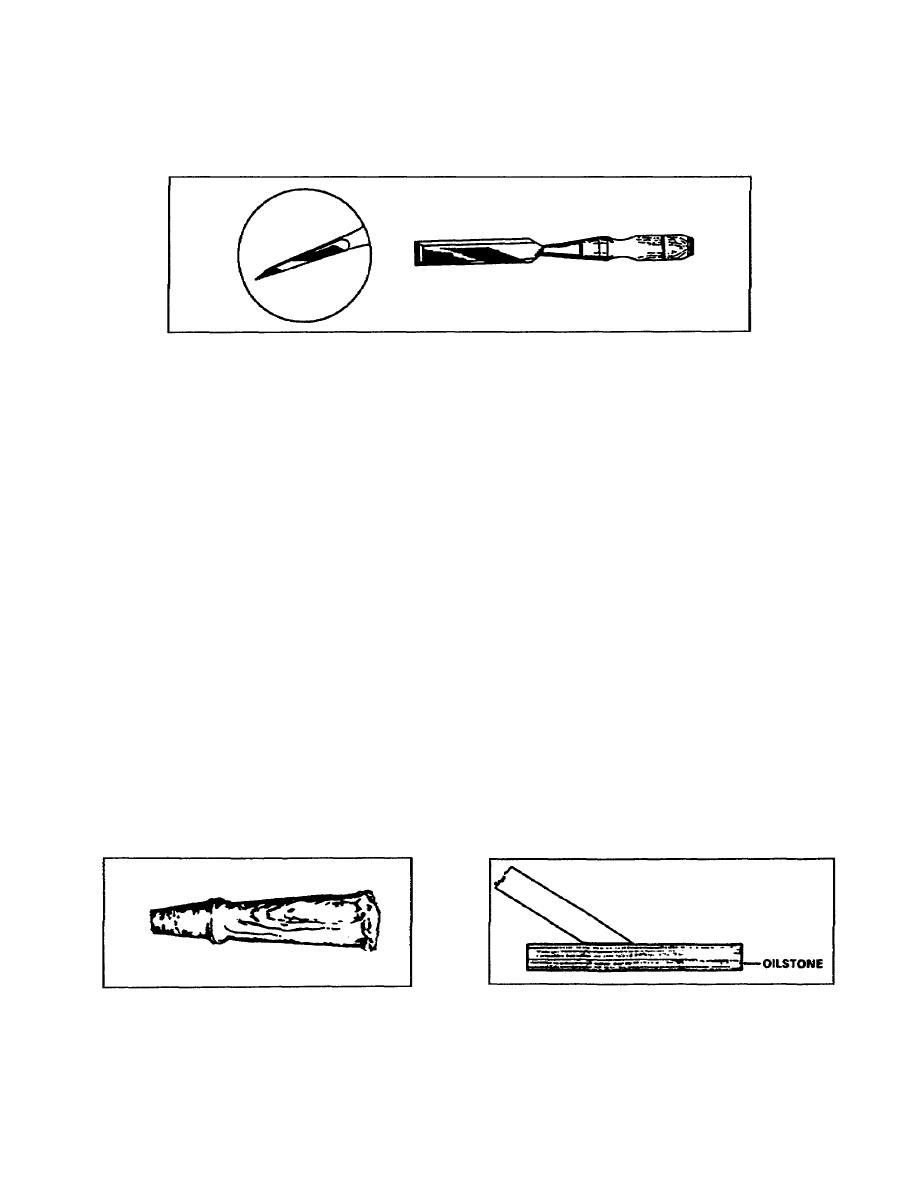

(3) Framing Chisel. A framing (or mortise) chisel (Figure 2

19) is a heavyduty tool, which is used for heavy work. These

chisels have an iron ring fitted to the end of the handle to prevent

splitting when it is struck with a heavy mallet.

Figure 2-19.

Framing chisel

(4) Slick Chisel. Any chisel having a blade wider than 2

inches is called a slick chisel. Regular sizes range from 2 1/2 to 4

inches. They are used on large surfaces where there is considerable

material to be removed or where unusual power is required.

b. Care and Use of SharpEdged Cutting Tools. For most effective

use, keep all chisels properly ground and sharp. When chisels are

not being used, keep them in a toolbox or other approved storage

place such as a rack, to prevent dulling or nicking the cutting

edges. To prevent rusting during storage, coat the metal portion of

the chisel with light oil.

(1) Replacing the Wood Chisel Head. A wood chisel with a

mushroomed head (Figure 220) should be replaced immediately, because

a mallet can glance off its mushroomed surface easily and spoil the

work surface or cause injury.

NOTE: A slightly battered wood handle can be smoothed with a wood

rasp and sandpaper.

(2) Whetting the Cutting Edge. The cutting edge of the wood

chisel can be kept in shape by whetting it on an oilstone (Figure 2

21), unless its edge is nicked or the bevel has become too rounded

with careless whetting. In this case, the chisel must be ground,

taking care the bevel is ground straight. Keep the length of the

bevel about two times the thickness of the unbeveled part of the

blade.

Figure 2-21. Whetting a chisel

Figure 2-20.

Mushroomed chisel

cutting edge

head

EN5155

2-10

Previous Page

Previous Page