(e) Perilla oil. This oil is extracted from the seeds of the perilla plant grown in

Manchuria. It is extensively used in the manufacture of varnish because of its superior drying and film-

forming qualities.

(f) Fish oil. This oil is mostly extracted from the menhaden and the pilchard fish. It is

satisfactorily used for covering hot surfaces, such as smoke stacks, where hard-drying paints are not

suitable. It is not recommended for interior use.

(g) Castor oil. This oil is produced from the castor-oil plant. Its use has increased since

being accepted as a satisfactory replacement for tung oil.

(2) Driers.

(a) Driers are catalytic agents. They hasten film hardening when added to a drying oil or

a paint or varnish that contains oil. The most common driers used in paint are oil-soluble naphthenates

of cobalt, zinc, manganese, or lead. Lead driers promote hard drying throughout the thickness of the

film and influence the polymerization rate of the vehicle more than they do the oxidation rate. Lead

driers are not as strongly catalytic as others in promoting the drying of paint films. Cobalt driers assist

oxidation strongly and, if used alone, may cause wrinkling because of rapid drying of the outer layer of

the film.

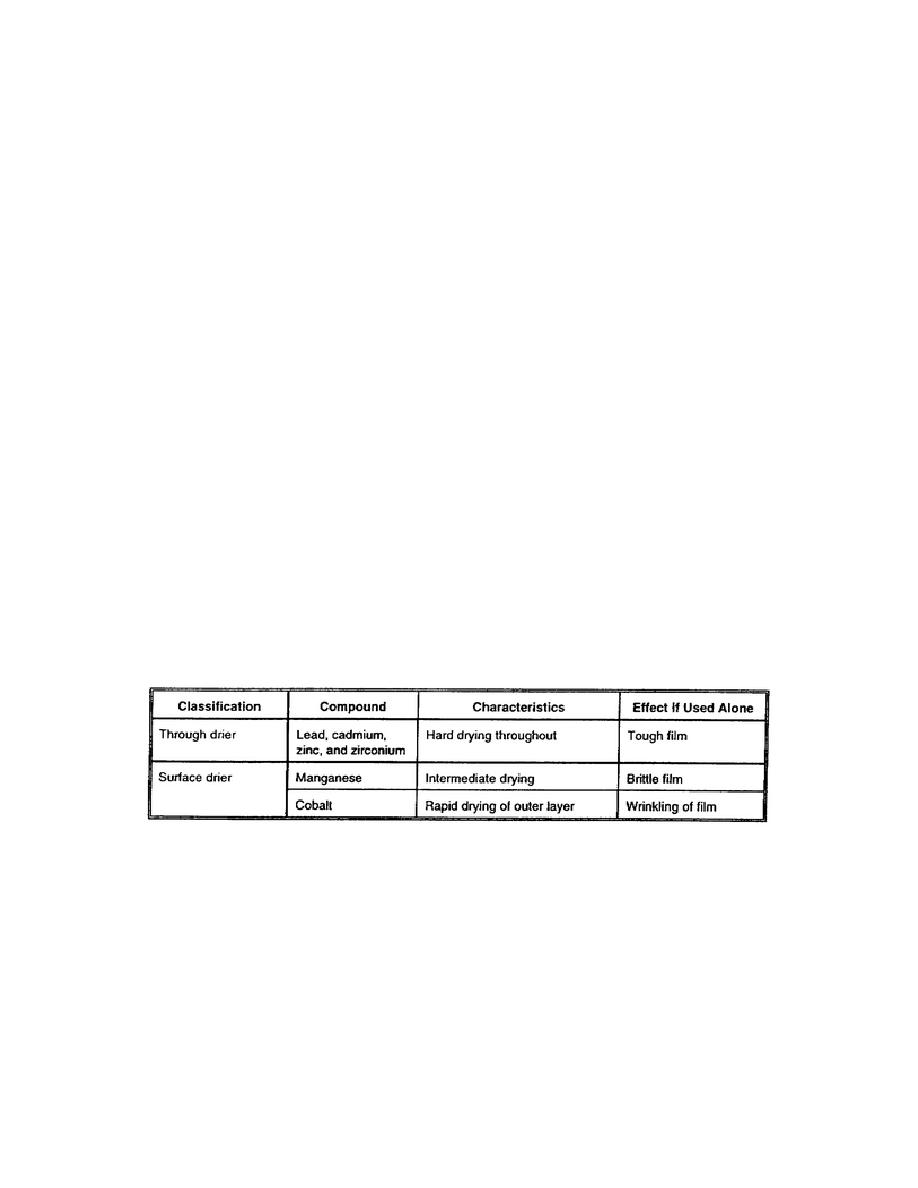

(b) Driers are classified as through driers and surface driers. Through driers are

compounds of lead, cadmium, zinc, or zirconium. Surface driers are compounds of cobalt and

manganese. Use surface driers in conjunction with through driers to prevent wrinkling, uneven drying,

and such. Table 2-1, summarizes individual drier characteristics and their effect on the film if the drier

is used alone.

Table 2-1. Characteristics of driers

(c) When using a given paint or vehicle you may make use of one or both of the drier

classifications, depending on the nature of the paint product. If too much drier is used or is improperly

combined, the drier mixture may adversely affect the durability of the film or may not allow the paint

film to harden. It is safer to purchase finished paint products with driers added whenever practicable,

since the addition of driers in the field is readily susceptible to error.

(3) Resins. Natural and synthetic resins available to the paint industry are so numerous and

varied in properties that they will only be mentioned. This same complexity

EN0562

2-8

Previous Page

Previous Page