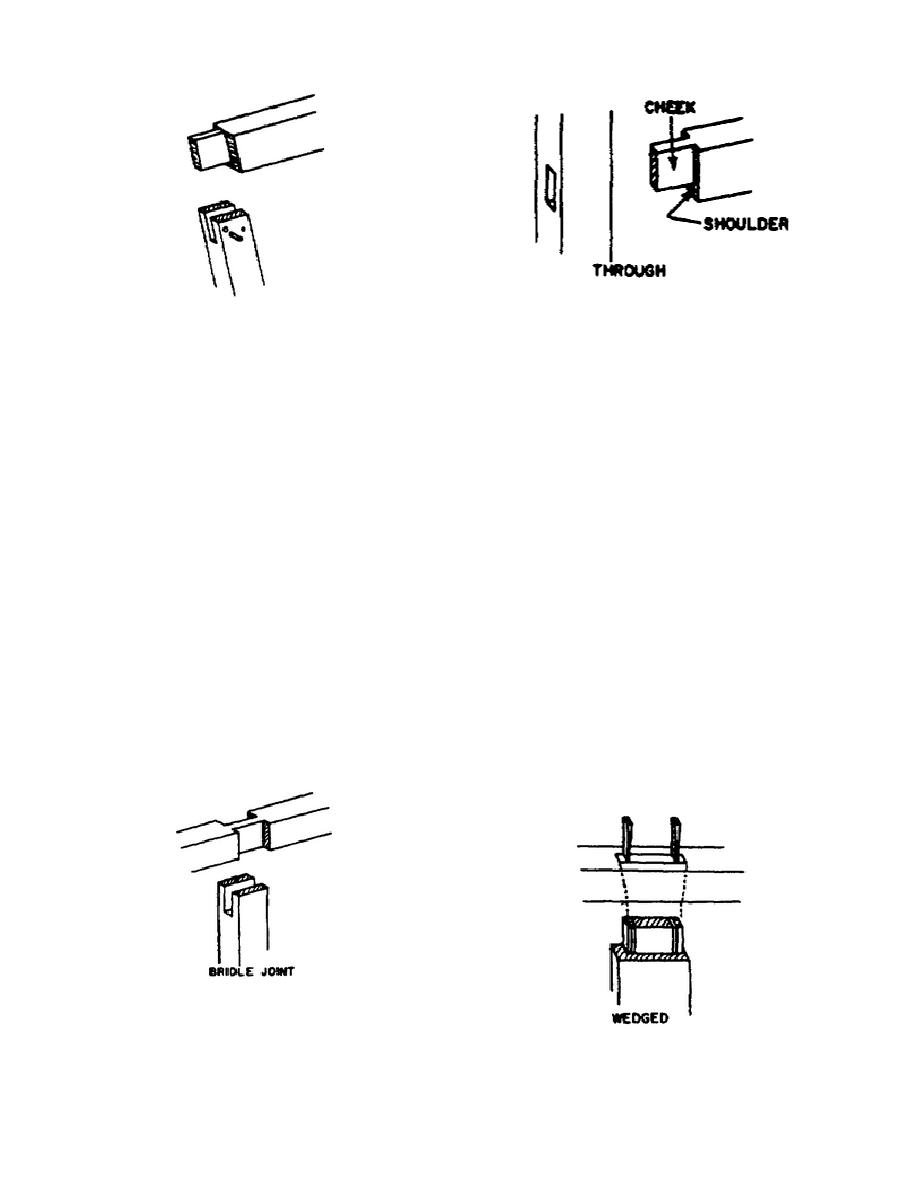

Figure 8. Through mortise and tenon joints.

Figure 6. Open mortise and tenon joints.

joints are those in which the mortise extends completely

a plain miter joint. Shown in figure 5, C, is one way of

through one member. (See fig. 8.) When wedges are

inserting a spline in a miter joint. A miter joint with a

driven into the end of the tenon, it is called a wedged

spline is usually fastened only with glue. Joints of this

mortise and tenon joint, as illustrated in figure 9. For

type, if made with hand tools, must have each piece

rough knockdown or outside furniture, the tenon can be

marked. However, if power machinery is used, then only

cut longer than the depth of the mortise, with a hole

one layout is necessary to set up the machine.

drilled into the protruding part of the tenon and a wedge

2-17. Mortise and tenon joints. The mortise and tenon

driven close to the outer face of the member which has

joint is one of the oldest and most used joints in cabinet

the mortise cut into it. (See fig. 10.) When this is done, it

construction. The numerous variations of this type of

is called a keyed mortise and tenon joint.

joint provide ample choices for framing doors, panels,

c. Blind mortise and tenon joints. These joints are

tables, chairs, and cabinets. Of these variations, we will

those in which the mortise and tenon do not go

discuss four: open, through, blind, and haunched mortise

completely through the mortise member, as shown in

and tenon joints.

figure 11. They are used for doors, table legs, rails, and

a. Open mortise and tenon joints. These joints are

panels when it is desired that no part of the mortise or

sometimes called slip joints, as illustrated in figure 6. As

tenon be seen after the work is assembled.

you can see, the mortise is cut completely through the end

d. Haunched mortise and tenon joints. These joints

of one piece, which is open on three sides, and the tenon

are used when a groove is cut into the framing where the

is slipped into this open mortise. It is a strong joint and

mortise and tenon will fit. Figure 12 illustrates how the

can be used on various types of frames. This type of

tenon is cut to fit into the groove after the tenon is

mortise and tenon joint can be nailed, screwed, pegged, or

inserted into the mortise. These are used often for

glued for added strength. Another version of this type of

framework where grooves are cut for panels.

joint is the bridle joint, illustrated in figure 7. However,

2-18. When making a mortise and tenon joint, make

in this version one member is joined in the center.

sure the tenon has at least one shoulder where the greatest

b. Through mortise and tenon joints. These

stress is anticipated. For additional strength on wide

stock, provide a double

Figure 7. Bridle mortise and tenon joints.

Figure 9. Wedged mortise and tenon joints.

5

Previous Page

Previous Page