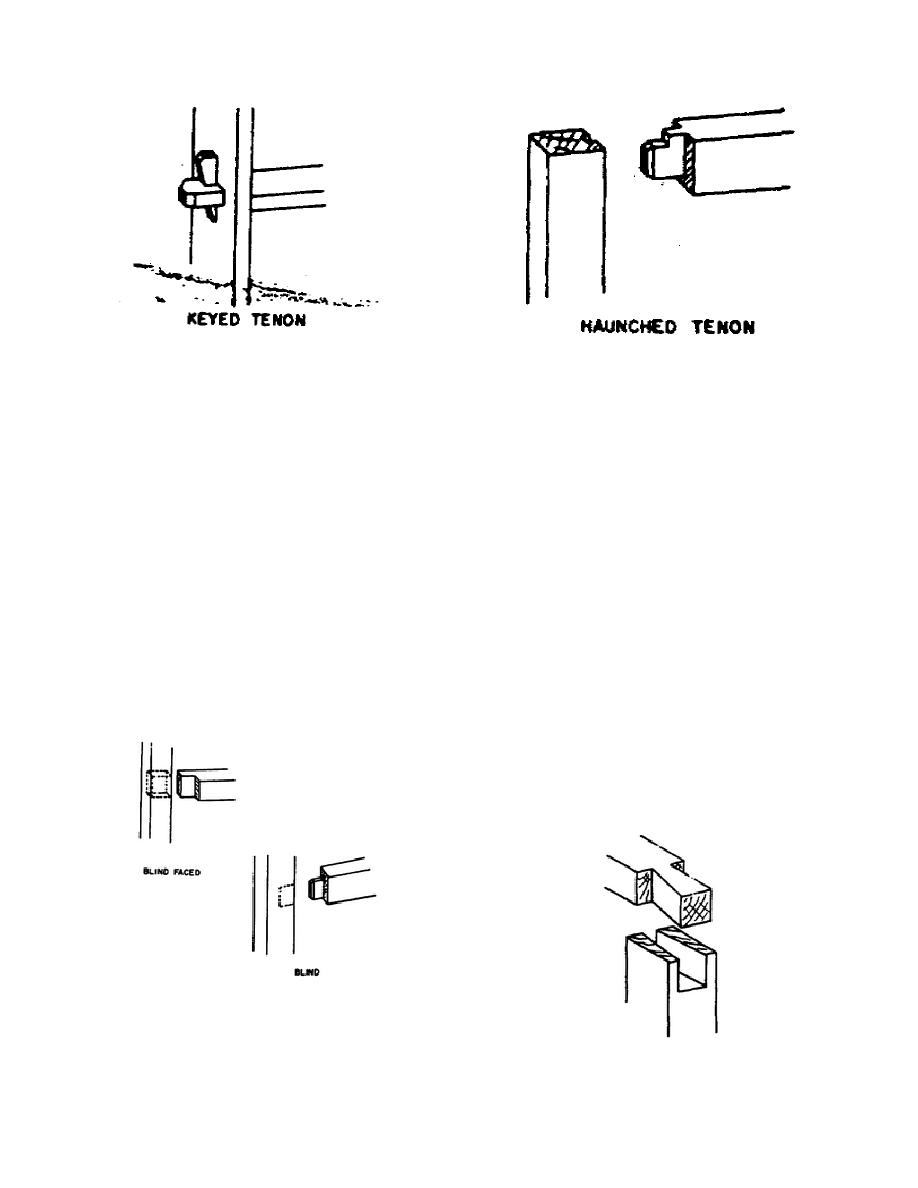

Figure 10. Keyed mortise and tenon joints.

Figure 12. Haunched mortise and tenon joints.

mortise and tenon. This eliminates a springy tenon and

figure 14. They are used primarily for corners of small

gives more shoulders which can rest against the sides

boxes.

which have the greatest stress. Before starting any

2-20. There are a few good rules to follow when

mortise and tenon joints, be sure the stock is squared. To

making dovetail joints. In softwood, the tails should be

determine the proper thickness of a tenon, compare a with

wider than they are deep. For hardwood, the face (widest

the member of which it is a part. The thickness should be

part) of the pins, or fingers, should be at least three-

approximately one-third the thickness of the member.

fourths of the thickness of the wood.

The tenon should fit snugly but not bulge the sides of the

2-21. It is not feasible to try to explain each step in

mortise or have to be driven into it.

laying out the fingers and tails of each type of dovetail

2-19. Dovetail joints. One of the strongest and neatest

joint, but it does take experience and patience to make

of all joints used in cabinetwork is the dovetail joint. For

them.

a corner joint, the dovetail is considered a mark of good

2-22. Dowel joints. Similar to the one shown in figure

workmanship, and a good fit can only be achieved by

15, dowel joints are used extensively to reinforce boards

accurate and painstaking labor:

that are glued edge to edge or otherwise butted together.

a. Single dovetail joints, like the one shown in

The dowels are made of birch and the standard diameter

figure 13, are used for drawing boards, tabletops.

sizes range from three-sixteenths to one inch. When you

drawers, etc.

bore holes for the dowels, use a bit the same size as the

b. Finger, or box, dovetail joints are those which

dowel. The size of the dowel should be large enough to

have square fingers and tails, as shown in

support the intended job but not so large as to weaken the

work rather than strengthen it. The diameter should be

approximately one-third to one-half the thickness of the

stock on which it is being used, and all holes must be

bored straight so that the dowel will not be forced into a

bent position. It is good practice to

Figure 11. Blind mortise and tenon joints.

Figure 13. Single dovetail joints.

6

Previous Page

Previous Page