e. Whether the fasteners are to be visible or

contact over the entire area and that there are no air

bubbles or foreign particles between the wood layers.

concealed.

2-2. A product of the cabinetmaker is no stronger

2-6. Classification by Grain Direction. In our study

than its weakest joint. However it is well to remember

of joints, let's first consider their classification pertaining

that you need not be a skilled perfectionist to produce a

to grain direction. By this we mean the length, face, edge,

good joint. If you pan your work, visualize the various

and end of a board.

2-7. Parallel grain joints. Parallel grain joints are

steps in their proper sequence, and perform these steps to

the best of your ability, you can succeed in making joints

those in which the grain in the jointed pieces runs in the

that fit well and serve their purpose. A strong joint is one

same direction. There are two types of such joints: (1)

that is well fitted.

Parallel edge grain joints, which are used in joining wood

2-3. Many types of joints are used in woodworking;

edgewise; and (2) parallel right-angle joints, which are

however, in this section we will discuss only the

used in joining pieces of wood so that their faces are at

following classifications pertaining to cabinetmaking:

right angles and their grain parallel.

2-8. Right-angle joints. Right-angle joints are those

Parallel grain joints.

in which the grain of the woods meet at right angle when

Right-angle grain joints.

they are joined. There are three types of right-angle grain

Lap joints.

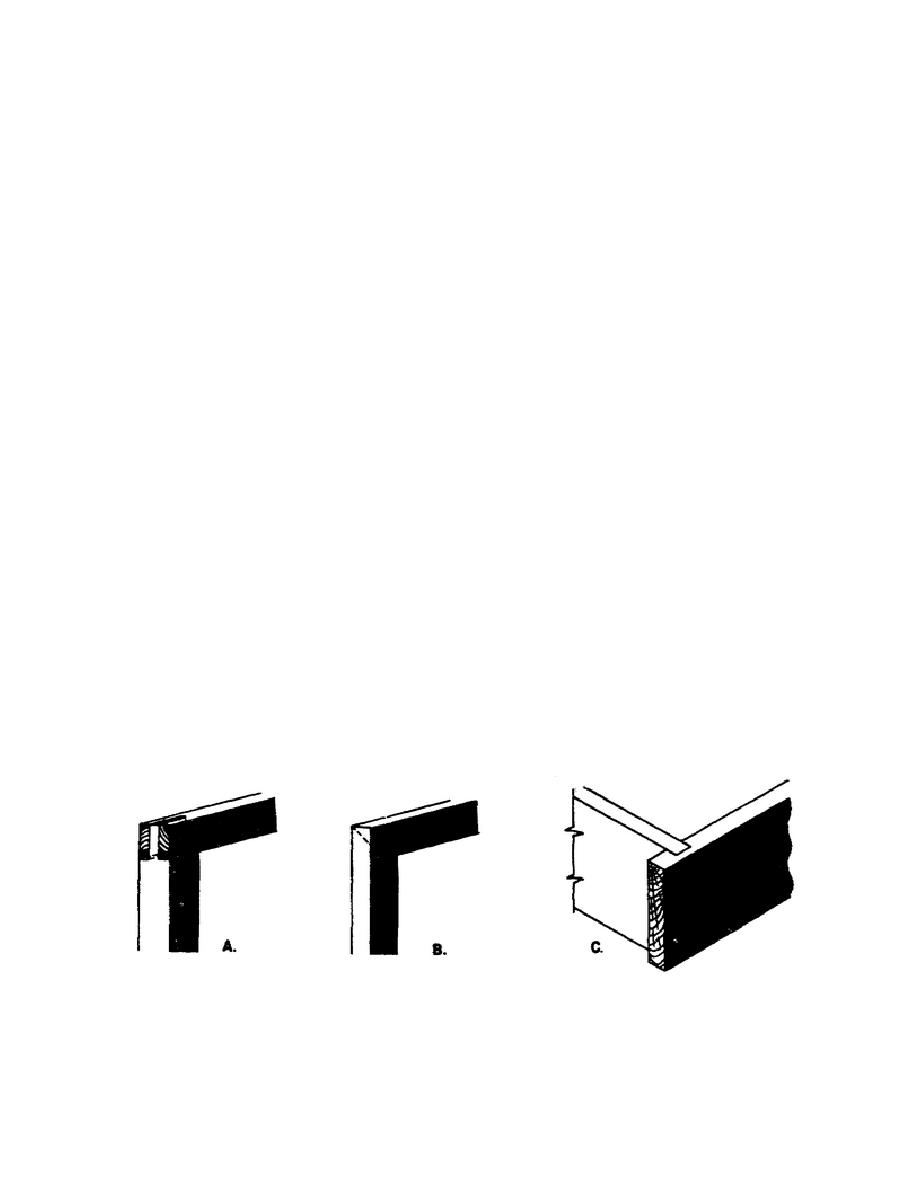

joints: (1) end-to-edge joints, in which the end of one

Grooved joints.

member is fitted to the edge of the other member (see fig.

Miter joints.

1, A); (2) oblique joints, where the graining of both

Mortise and tenon joints.

members is fitted end to end; and (3) end-to-face joints,

Dovetail joints.

where the end gain of one member is joined to the face of

Butt joints.

the other member (see fig. 1, C). The pain miter joint

shown in figure 1, B, is a good example of an oblique

2-4. This section will acquaint you with these

right-angle joint.

classifications, the types of joints covered by each, and

2-9. Classification by Construction Detail. We

where they are used, rather than with any detailed

have described the main classes into which all

descriptions of bow each kind of joint is laid out and

woodworking joints fall.

Now let's study joint

constructed.

classification with regard to construction detail.

2-5. The selection of a specific type of joint is

2-10. Lap joints. The lap joint a simple lap, or halved,

determined by the following factors:

joint made by cutting out equal half sections from both

a. Working qualities and strength of the material to

members which are to be jointed. There are several variations

be used.

of the lap joint. When the half sections are cut from the end

b. Whether the work is on the exterior or on the

of the members to be jointed and cross each other at right

interior and whether it is a movable or a stationary

angles, the joint is known as an end lap joint as shown in

project.

figure 2, A. If the members cross each other at right angles in

c. How the project will be fastened, such a nailed,

the center, the joint is called a cross lap joint, as

screwed, glued, or a combination of these.

d. Whether the grain is parallel or at right right

angles where the joint is fastened.

Figure 1. End-to-edge joints.

3

Previous Page

Previous Page