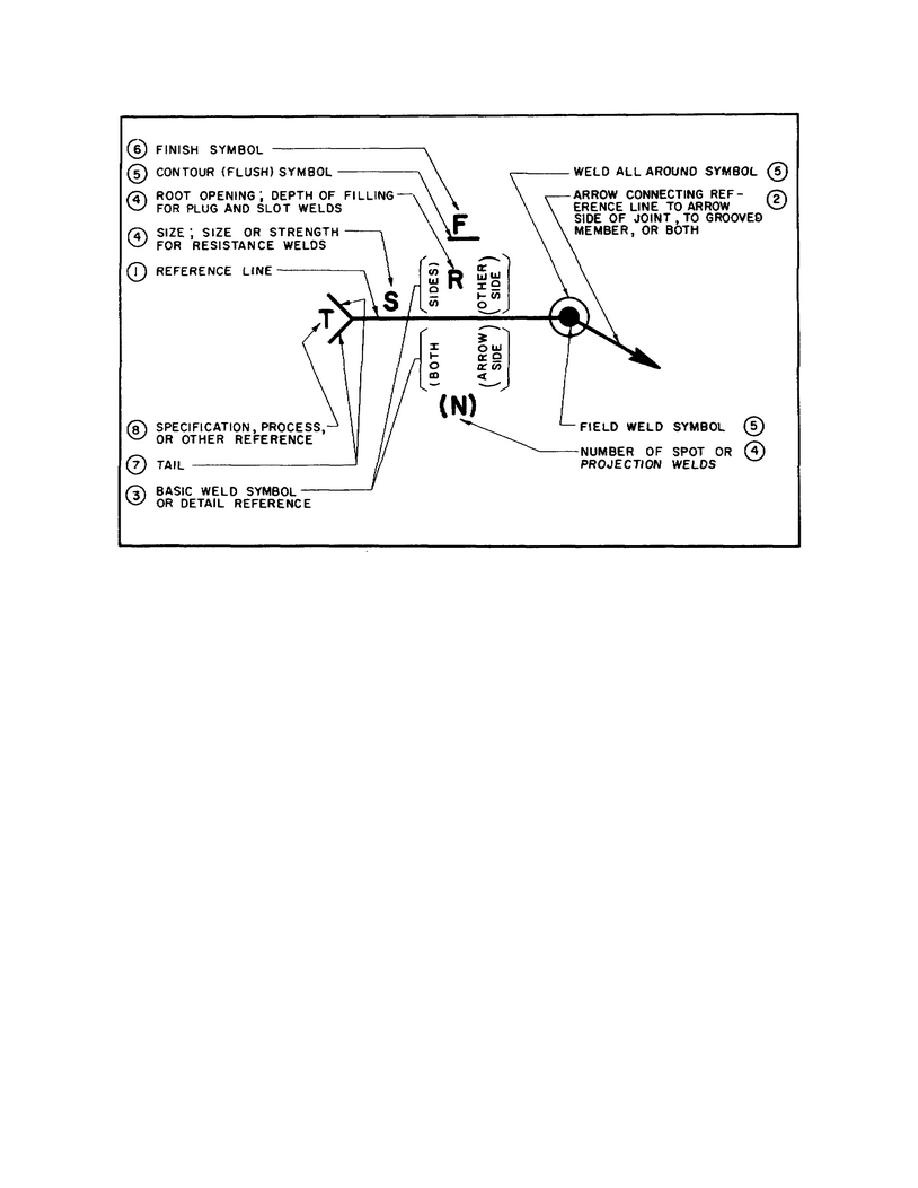

Figure 2-35. Standard location of elements of a welding symbol.

and contour of weld is to be flush, respectively.

symbol designates arrow side, other side, or both

sides to be welded.

(6) Finish. The finish symbols indicate the

method of finishing (C = chipping, M = matching, G

2-20. STRUCTURAL DRAWINGS

= grinding, R = rolling, H = hammering) and not the

degree of finish.

Structural drawings usually consist of some or

all of the elements described in the following

(7) Tail. The tail is only used to set off the

paragraphs.

notation that designates a definite process or

specification or other references considered as

a. Shop Drawings. Shop drawings show the

element (8) of the welding symbol. When no

details of the fabrication of parts and methods of

notation is required, the tail may be omitted from the

assembly of the structural members that are prepared

welding symbol.

in special fabricating shops. Figure 2-37 illustrates

structural members (a beam and a column) fabricated

from a combination of rolled steel shapes. Figure 2-

(8) Specification, process, or other

references. This is a notation that indicates a

38 illustrates structural members of a welded steel

definite process or certain specifications or other

truss.

references. When the use of a definite process is

required, the process may be indicated by one or

(1) Working lines and working points.

more of the letter designations listed in tables 2-7 and

Shop drawings are made about light working lines

2-8.

laid out first along the centerlines of rivet gage lines

to form a skeleton of the assembled member. The

intersections of these working lines are called

d. Applications of Welding Symbols.

Applications of the welding symbol are shown in

working points

figure 2-36. Note how the location of the weld

81

Previous Page

Previous Page