TC 9-62

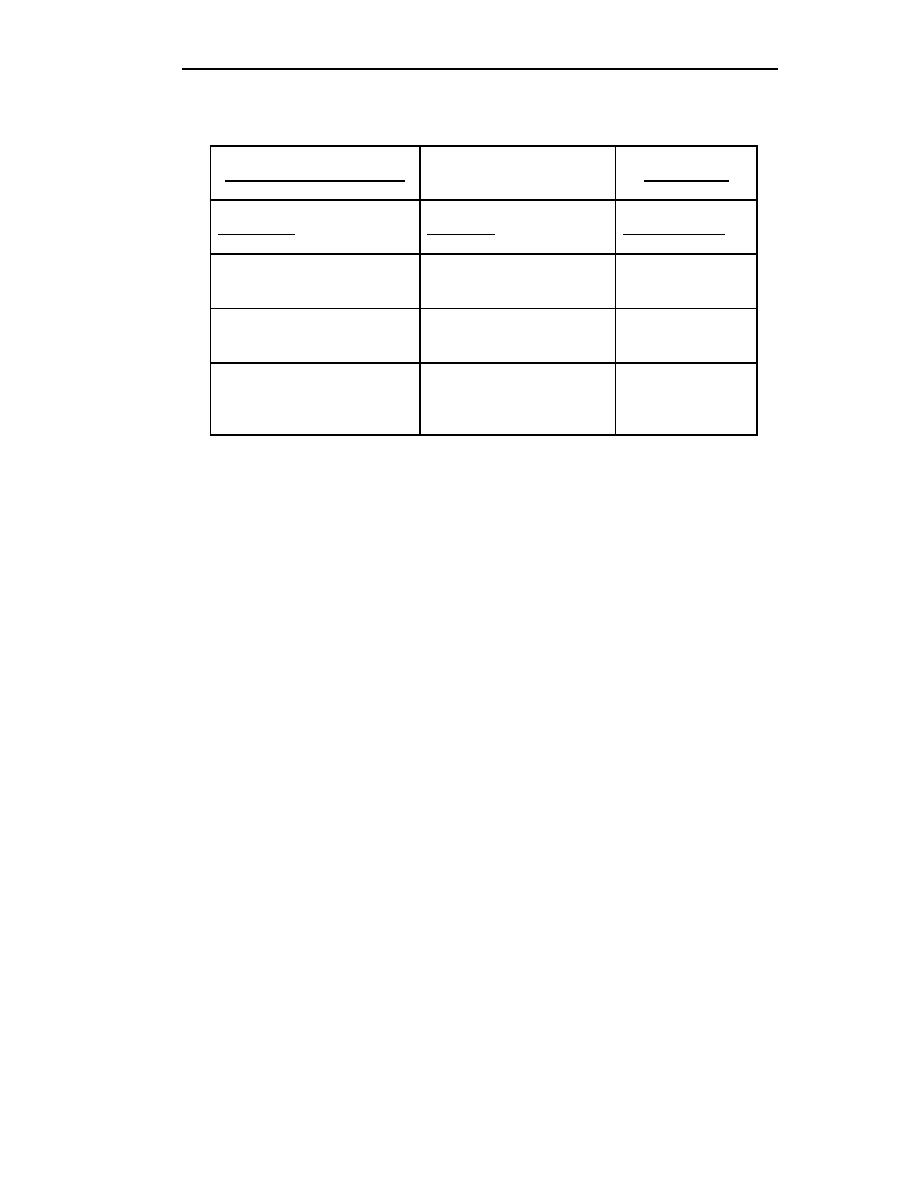

Table 2-2. Possible Transistor Problems

RESISTANCE READINGS

PROBLEMS

FORWARD

REVERSE

The transistor is:

LOW

LEAKING

(NOT SHORTED)

LOW

LOW

SHORTED

(SHORTED)

(SHORTED)

HIGH

HIGH

OPEN

SAME (NEARLY EQUAL)

SAME (NEARLY EQUAL)

DEFECTIVE

2-102. When testing PNP or NPN transistors, you should remember that the actual

resistance values depend on the ohmmeter scale and the battery voltage. Typical forward

and reverse resistances are insignificant. The best indicator for showing whether a

transistor is good or bad is the ratio of forward-to-reverse resistance. If the transistor you

are testing shows a ratio of at least 30 to 1, it is probably good. Many transistors show

ratios of 100 to l or greater.

MICROELECTRONICS

2-103. Up to now the various semiconductors, resistors, capacitors, and so on have been

considered as separately packaged components, called DISCRETE COMPONENTS. We

will now look at some of the more complex devices that contain complete circuits

packaged as a single component. These devices are referred to as INTEGRATED

CIRCUITS and the broad term used to describe the use of these devices to miniaturize

electronic equipment is called MICROELECTRONICS.

2-104. With the advent of the transistor and the demand by the military for smaller

equipment, design engineers set out to miniaturize electronic equipment. At first, their

efforts were frustrated because most of the other components in a circuit such as resistors,

capacitors, and coils were larger than the transistor. Soon these other circuit components

were miniaturized, thereby pushing ahead the development of smaller electronic

equipment. Along with miniature resistors, capacitors, and other circuit elements, the

production of components that were actually smaller than the space required for the

interconnecting wiring and cabling became possible. The next step in the research process

was to eliminate these bulky wiring components. This was accomplished with the PCB.

2-105. A PCB is a flat, insulating surface on which printed wiring and miniaturized

components are connected in a predetermined design and attached to a CB. Figure 2-23

shows a typical PCB. Notice that various components are connected to the board and the

printed wiring is on the reverse side. With this technique, all interconnecting wiring in a

piece of equipment (except for the highest power leads and cabling) is reduced to lines of

conducting material (copper, silver, aluminum, or gold) deposited directly on the surface of

an insulating "circuit board." Since PCBs are readily adapted as plug-in units, the

2-32

TC 9-62

23 June 2005

Previous Page

Previous Page